Single-Crystal Metal Substrates: Unlocking Performance in Advanced Materials Research

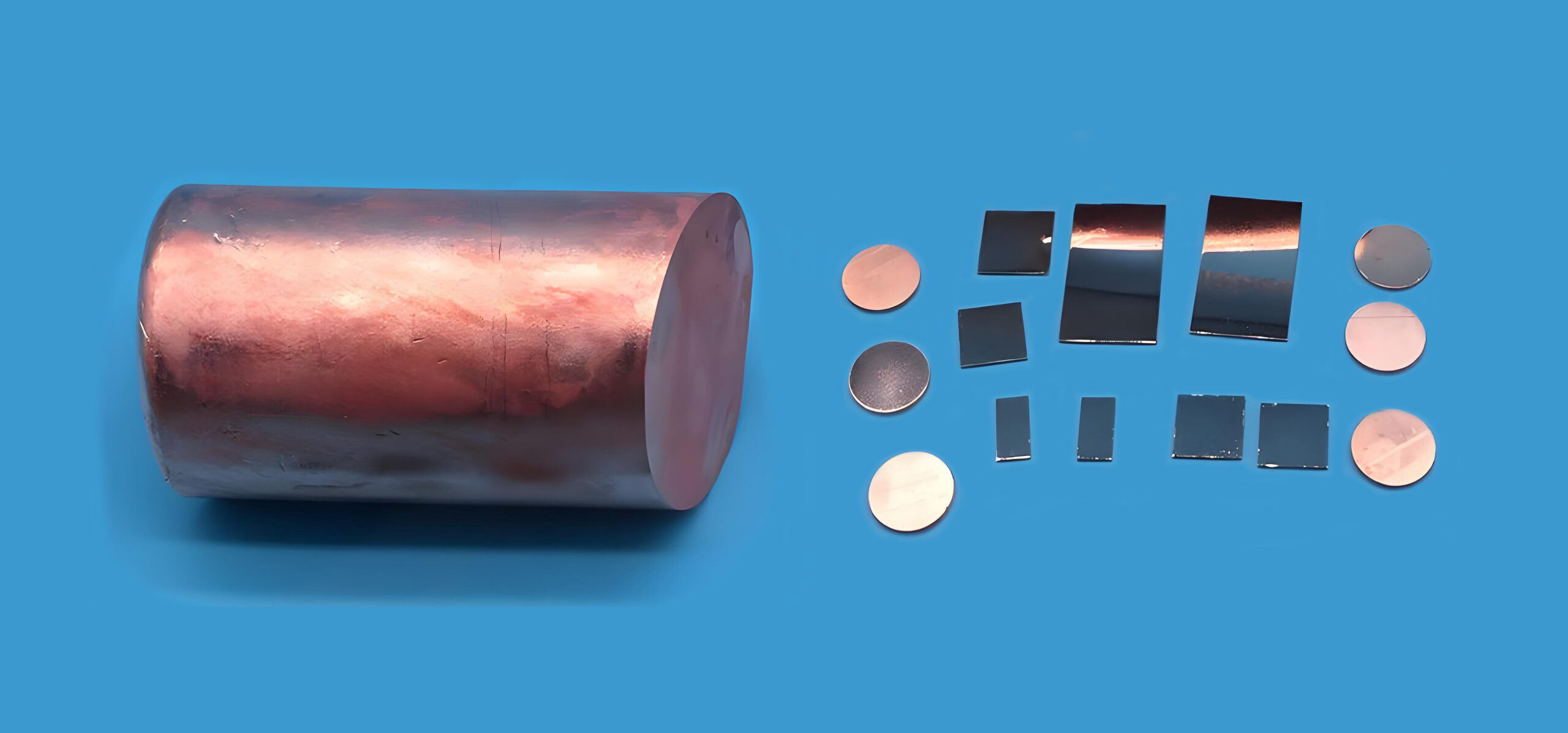

Single-crystal metal substrates such as Aluminum (Al), Copper (Cu), Magnesium (Mg), and Nickel (Ni) play a pivotal role in materials science, thin-film growth, and microelectronics. Unlike polycrystalline materials, single-crystal substrates exhibit uniform atomic orientation, providing an ideal template for epitaxial growth, surface analysis, and catalytic research. As device miniaturization and precision materials engineering advance, these substrates are increasingly vital for achieving controlled microstructures and reproducible physical properties.

1. The Science Behind Single-Crystal Metal Substrates

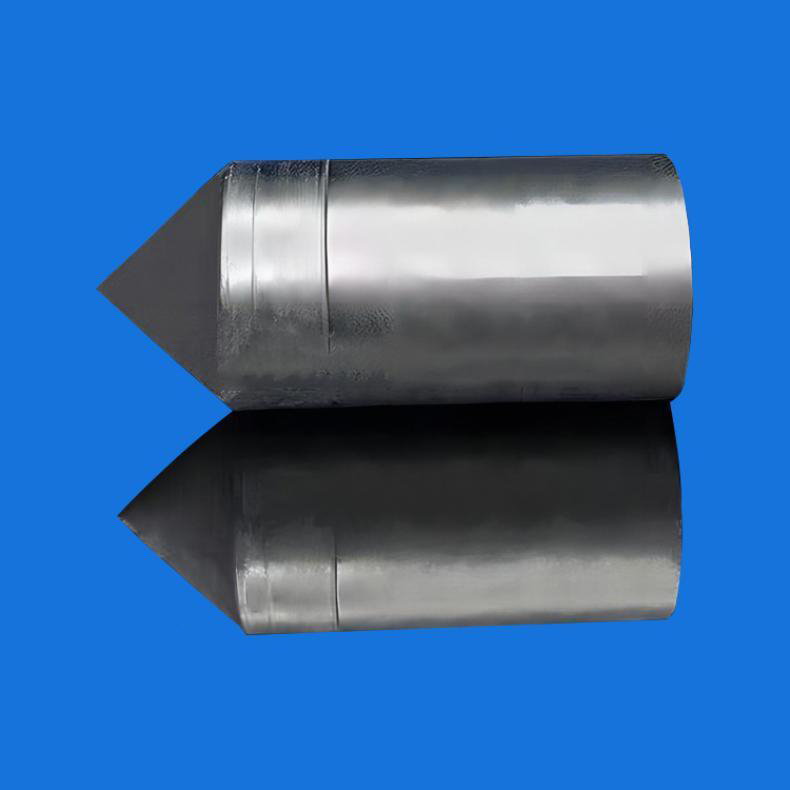

Single-crystal metal substrates are characterized by a continuous lattice without grain boundaries, resulting in predictable surface energy, thermal behavior, and mechanical integrity. They are commonly fabricated using methods like Czochralski pulling, Bridgman growth, or zone melting, depending on the material.

For example:

Reference: Chen, Z. et al., “Epitaxial Growth of Graphene on Metal Single-Crystal Substrates,” Nature Materials, 2021.

2. Key Technical Properties

| Material | Orientation | Melting Point (℃) | Thermal Conductivity (W/m·K) | Electrical Conductivity (%IACS) | Application |

|---|---|---|---|---|---|

| Al | <100>, <111> | 660 | 235 | 61 | Optical coatings, MEMS, reflective films |

| Cu | <100>, <111> | 1085 | 398 | 100 | Graphene growth, microelectronics |

| Mg | <0001> | 650 | 160 | 39 | Lightweight substrates, thin-film deposition |

| Ni | <100>, <111> | 1455 | 90 | 22 | Catalysis, 2D materials, magnetic films |

Data Source: ASM Handbook, Vol. 3, Alloy Phase Diagrams, 2020 Edition.

3. Applications Across Industries

2D Materials and Graphene Growth

Cu(111) and Ni(111) single crystals are standard substrates for CVD graphene synthesis, providing atomically flat surfaces that promote monolayer uniformity. Their high crystallinity ensures minimal defect formation and facilitates reproducible film quality.

Optical and Photonic Devices

Single-crystal Al substrates are valued for their high reflectivity (≈92% in visible range) and corrosion resistance, making them ideal for optical mirrors, reflective coatings, and laser cavity components.

Catalytic and Surface Science Research

Ni(100) and Cu(111) single crystals serve as model catalysts in surface reaction studies, enabling fundamental understanding of adsorption, diffusion, and reaction kinetics at atomic levels.

Advanced Microelectronics

Metal single-crystal substrates act as seed layers or underlayers for thin-film transistor electrodes, interconnects, and electronic packaging, ensuring consistent conductivity and minimizing electromigration.

4. Advantages Over Polycrystalline Materials

5. Future Outlook

As material design continues to integrate AI-driven prediction models and nanostructure control, single-crystal metal substrates will remain indispensable for high-precision manufacturing, energy research, and quantum device fabrication. Innovations in crystal growth techniques and ultra-high-purity refining are expected to further improve defect density control and scalability.

Conclusion

Single-crystal metal substrates represent a cornerstone in next-generation material engineering. With their superior crystallinity, purity, and structural precision, materials like Al, Cu, Mg, and Ni are empowering breakthroughs in thin-film growth, quantum electronics, and catalytic surface science.

Tinsan Materials continues to provide customized single-crystal substrates with defined orientations, high purity, and verified structural integrity – supporting research institutions and industrial partners worldwide.