Showing 13–24 of 40 results

-

$1,285.00

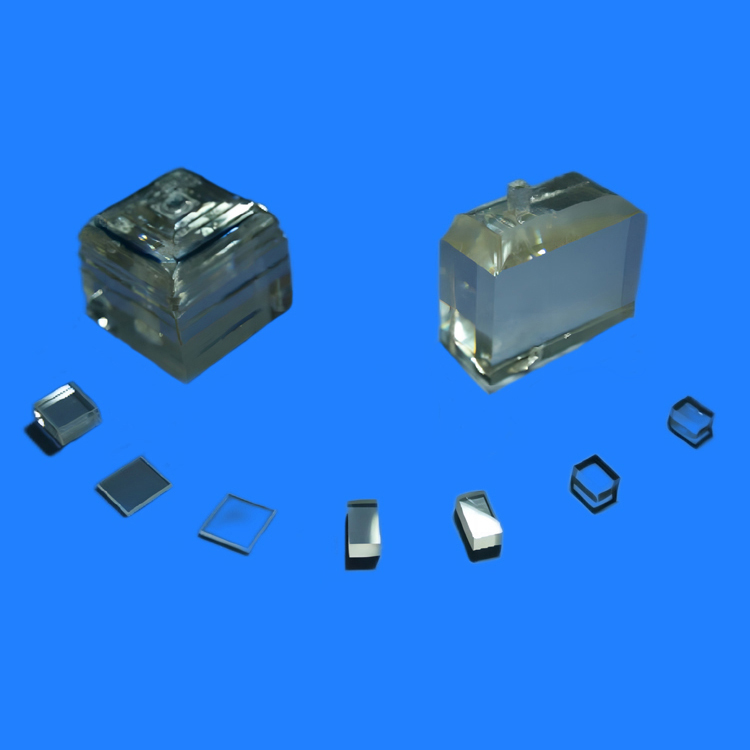

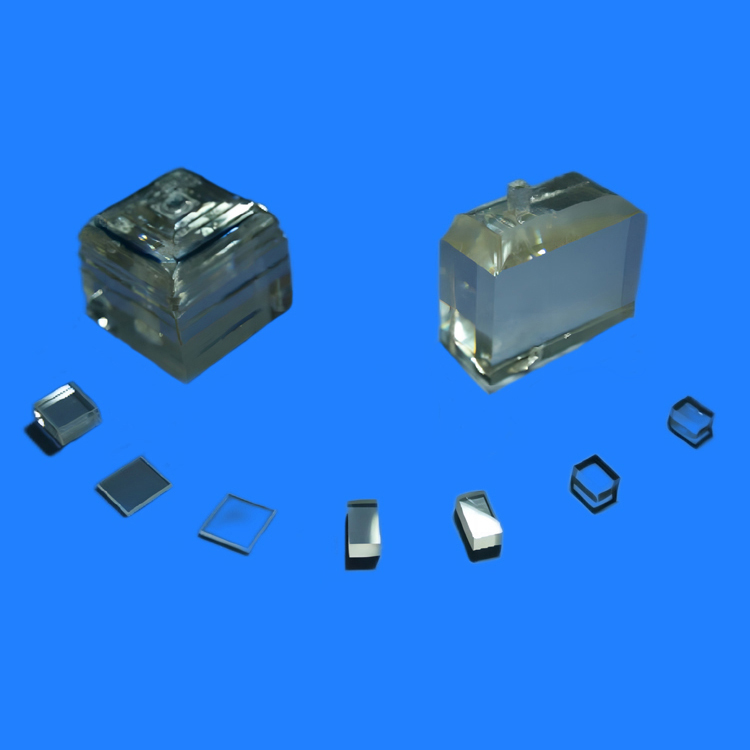

- Single crystal KTN with composition KTa₀.₅Nb₀.₅O₃

- <001> crystallographic orientation for optimal electro-optic performance

- Size: 10 × 10 × 0.5 mm

- High electro-optic coefficient (r33 ≈ 30–50 pm/V)

- Strong photorefractive effect

- Excellent dielectric tunability

- Wide optical transparency (~350 nm – 5500 nm)

- Low defect density and high optical uniformity

-

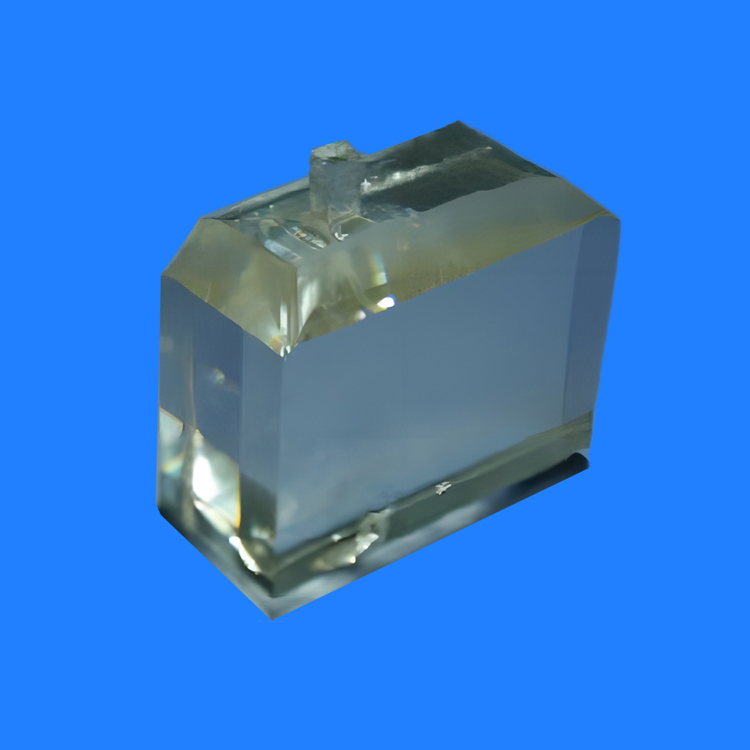

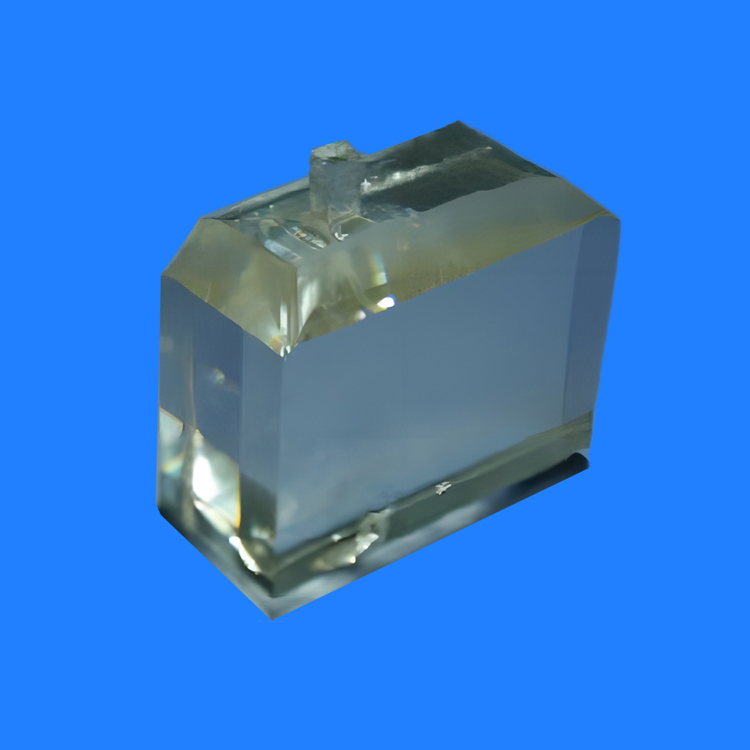

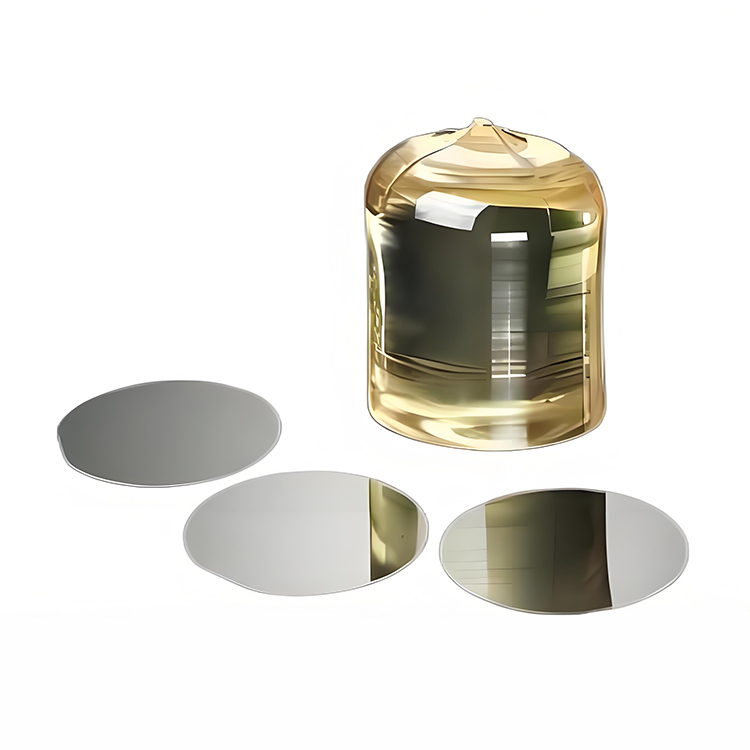

- High Nonlinear Optical Coefficient: ~15 times that of KDP crystals.

- Broad Transparency Range: 350 nm to 4500 nm.

- High Damage Threshold: >500 MW/cm² for nanosecond pulses.

- Excellent Electro-optic Properties: Suitable for Q-switching and Pockels cells.

- Large Angular Acceptance and Low Walk-off Angle: Easier beam alignment and higher conversion efficiency.

- Stable Physical and Chemical Properties: High mechanical strength and environmental stability.

-

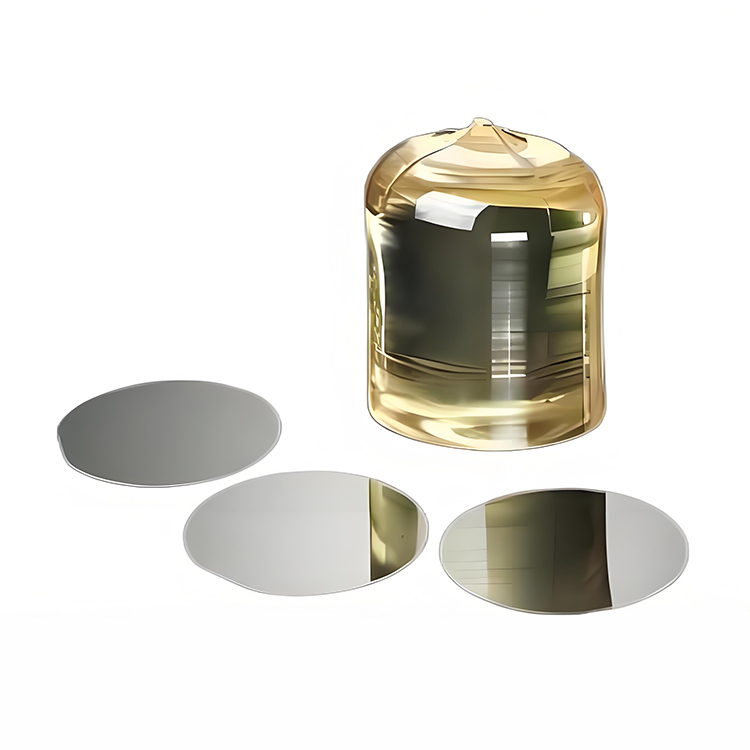

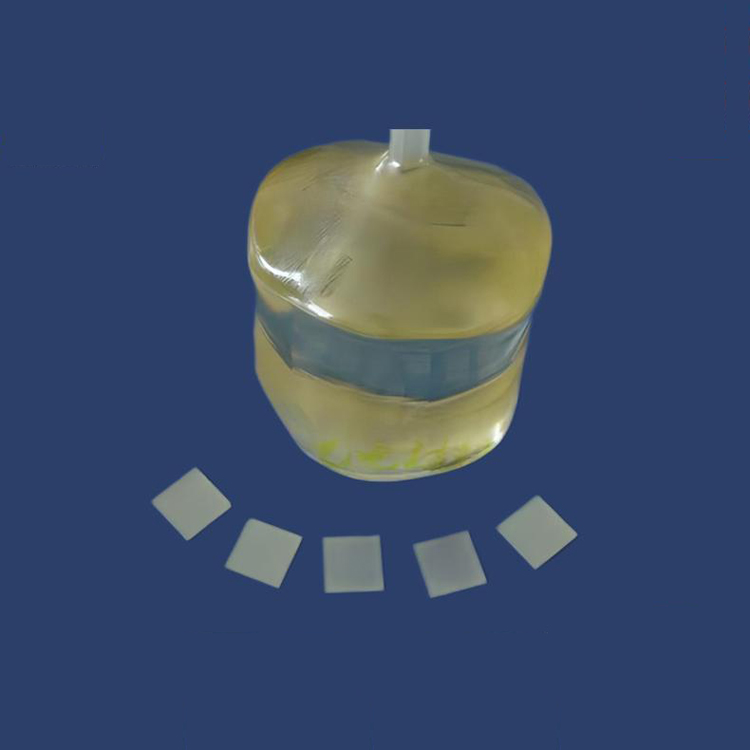

- Excellent Crystal Quality: Low dislocation density, high structural perfection.

- Ideal Lattice Match: Close lattice parameters with materials like YBCO, LSMO, PZT, and other perovskite oxides.

- High Thermal Stability: Suitable for high-temperature thin film deposition processes.

- High Dielectric Constant: Beneficial for microwave devices and tunable capacitors.

- Low Dielectric Loss: Ensures superior performance at high frequencies.

- Chemical Stability: Strong resistance to acids and bases.

- Atomically Smooth Surface: Achieved through advanced polishing and chemical etching processes.

-

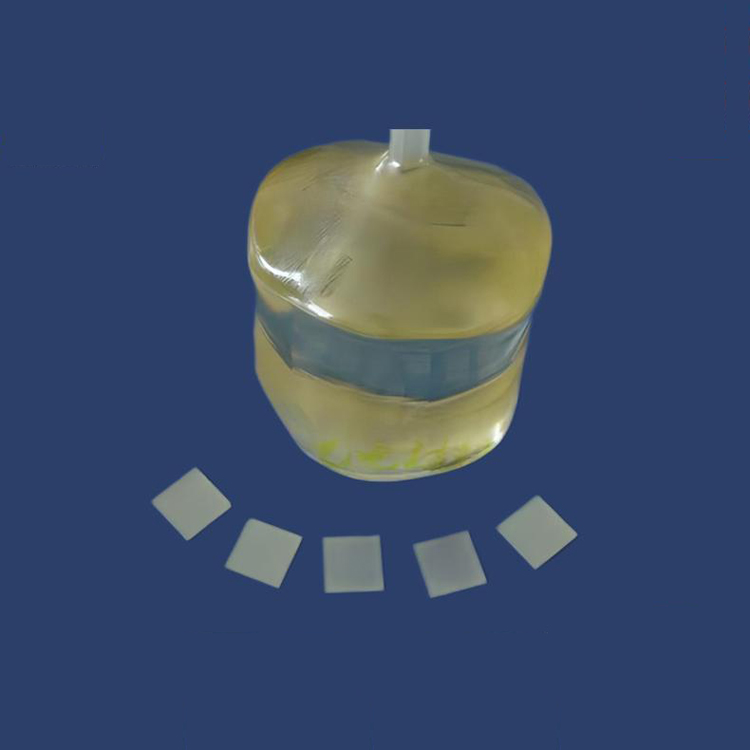

- High Thermal Stability: Excellent performance under high temperatures up to 1500°C.

- Wide Bandgap: Enables use in deep UV and high-power electronic applications.

- Superior Mechanical Strength: Resists thermal shock and mechanical stress.

- Excellent Lattice Match: Ideal substrate for GaN, AlN, ZnO, and other oxide semiconductor epitaxial growth.

- Low Dielectric Loss: Beneficial for microwave and RF device applications.

- Chemical Inertness: High resistance to acids, alkalis, and environmental degradation.

- Smooth, Defect-Free Surface: Essential for high-yield epitaxial growth and thin-film deposition.

-

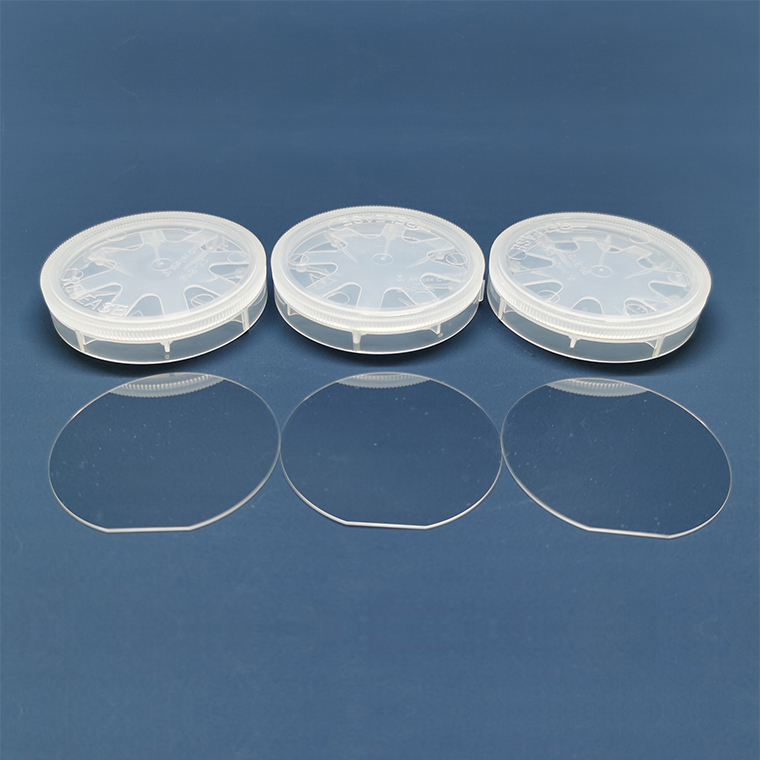

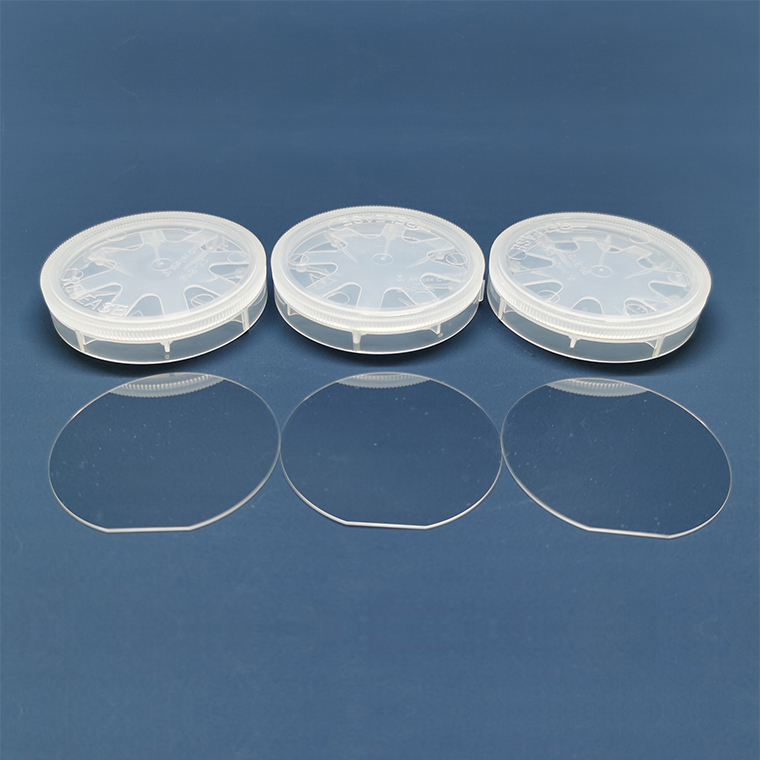

- Wide Transmission Range: Excellent optical transmission from 120 nm (VUV) to 6 μm (IR).

- Low Refractive Index: ~1.39 at 400 nm, advantageous for minimal Fresnel losses.

- Radiation Resistance: High durability against X-rays and high-energy particle irradiation.

- High Optical Homogeneity: Suitable for precision optics and laser systems.

- Good Mechanical Properties: Higher hardness compared to other VUV transparent materials like CaF₂.

- Low Birefringence: Enabling better performance in polarization-sensitive applications.

- Chemical Stability: Moderate chemical inertness; surface can be protected with appropriate coatings if needed.

-

- High Electro-optic Coefficient: Enables efficient light modulation

- Excellent Nonlinear Optical Properties: Ideal for frequency conversion processes

- Wide Transmission Range: Suitable for UV, visible, and infrared applications

- Strong Piezoelectric Response: Essential for SAW and MEMS devices

- Photorefractive Effect: Useful for holography and optical data storage

- Chemical and Thermal Stability: High reliability in demanding environments

- Availability of Stoichiometric and MgO-doped Variants: Reduces photorefractive damage and enhances performance in high-power lasers

- Precise Crystal Growth and Wafer Fabrication: Ensures high uniformity and low defect densities

-

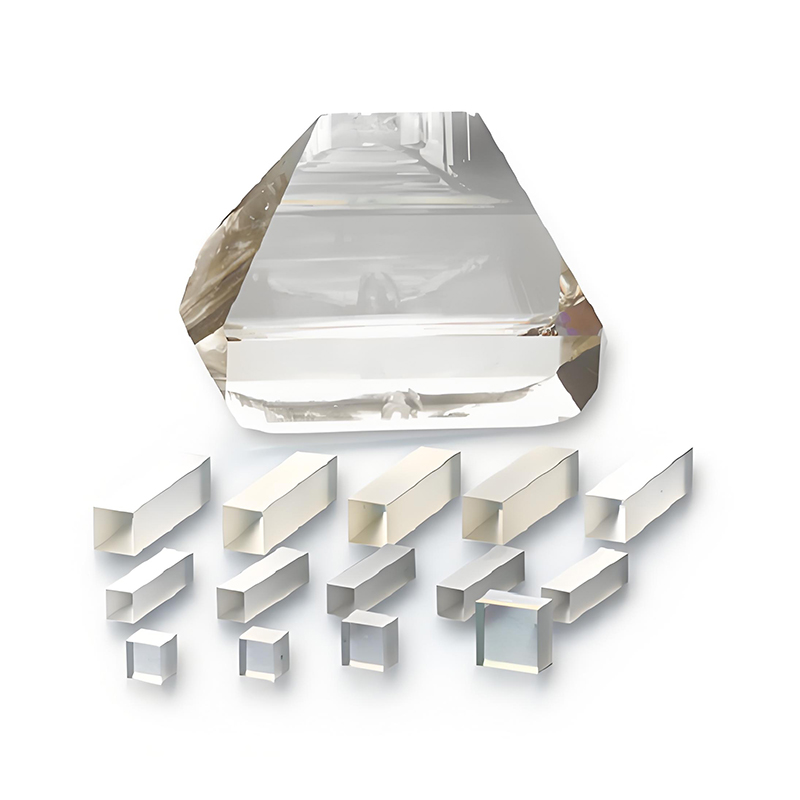

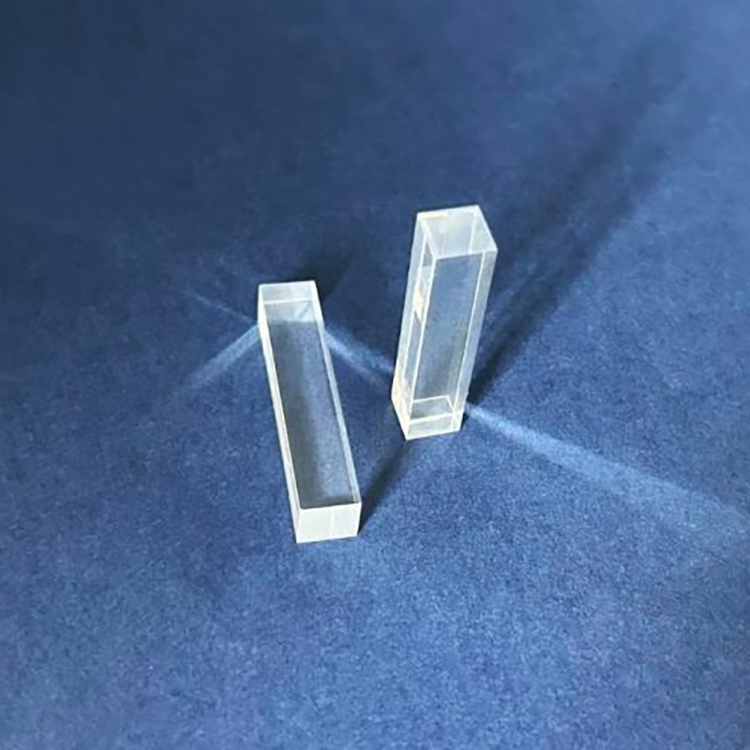

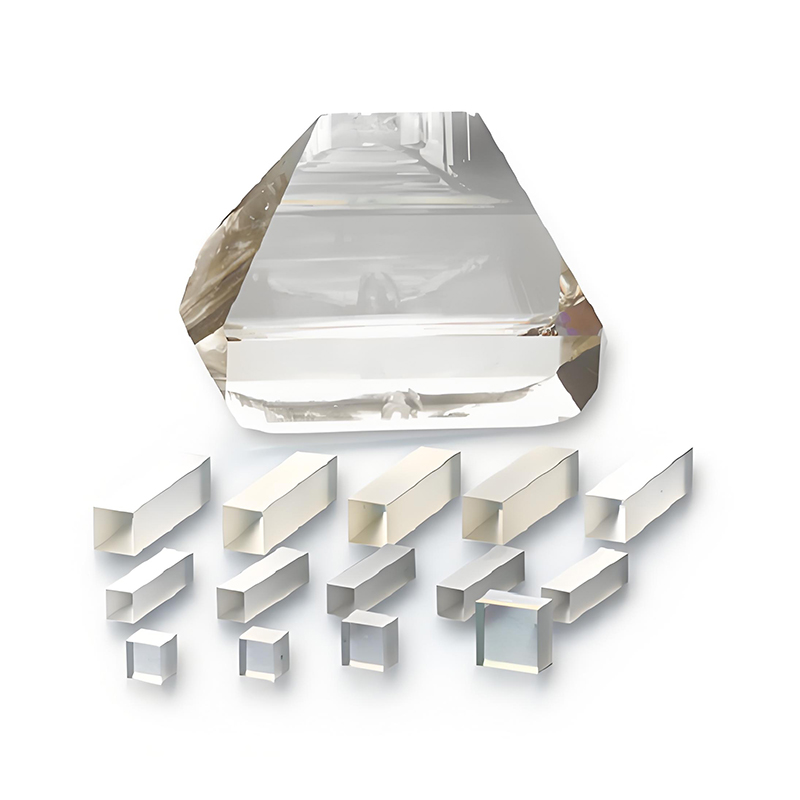

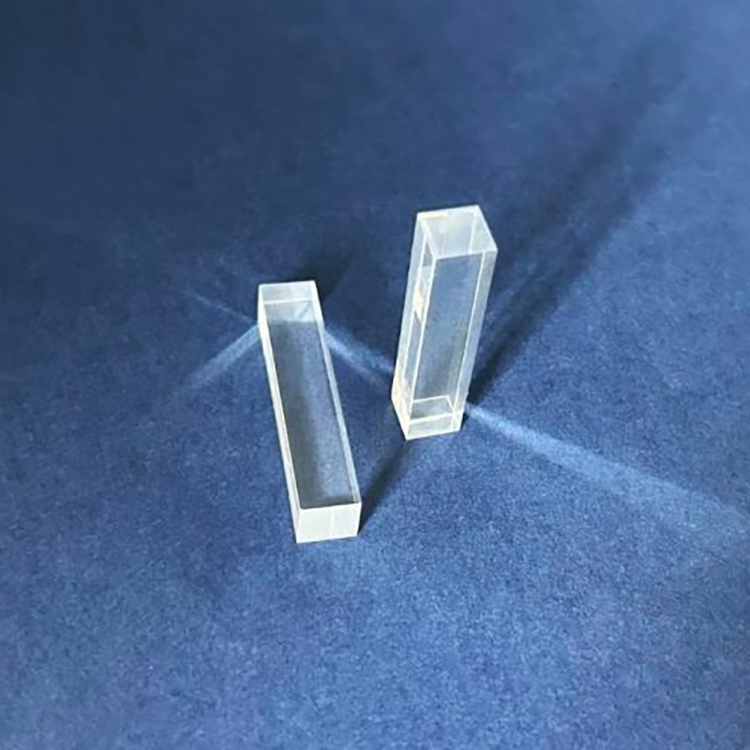

- Wide Transparency Range: 160 nm to 2600 nm

- Broad Phase-Matching Capability: Suitable for SHG, THG, OPO, SFG, DFG across UV to IR

- High Damage Threshold: >2 GW/cm² for 1064 nm, 10 ns pulse

- Low Walk-Off Angle: Ideal for high-beam-quality laser systems

- High Nonlinear Coefficients: Enables efficient frequency conversion

- Excellent Optical Homogeneity: Δn < 10⁻⁶/cm

- Good Mechanical Hardness: Mohs hardness ~6

- Stable Physical and Chemical Properties: Resistant to humidity and environmental degradation

- Nonhygroscopic: No special humidity control required

-

- Excellent Lattice Matching: Ideal match for many perovskite oxides such as YBCO, BST, and PZT

- High Thermal Stability: Maintains structural integrity under high temperatures

- Low Dielectric Loss: Suitable for microwave and dielectric applications

- High Crystallinity: Enables defect-free epitaxial film growth

- Good Mechanical Strength: Durable for various thin-film deposition processes

- Smooth Surface Finish: Atomic-level flatness for epitaxial growth

- High Chemical Stability: Resists degradation during processing

- Wide Application Range: Compatible with superconducting, ferroelectric, and oxide-based systems

-

- Lightest Structural Metal: Exceptionally low density for weight-sensitive applications

- Excellent Specific Strength: High strength-to-weight ratio

- Anisotropic Mechanical Properties: Ideal for deformation and slip system studies

- High Ductility at Elevated Temperatures: Improved formability in warm/hot conditions

- Good Machinability: Easier to process compared to other metals

- High Thermal Conductivity: Facilitates efficient heat dissipation

- Superior Homogeneity: Enables reproducible experimental results

- Corrosion Sensitivity: Useful for corrosion research and protective coating studies

-

- Excellent Thermal Stability: Suitable for high-temperature processing (melting point ~2135°C)

- Wide Optical Transmission: From 200 nm (UV) to 5000 nm (Mid-IR)

- Superior Mechanical Strength: High hardness and fracture toughness

- Low Thermal Expansion: 8.5 × 10⁻⁶ /°C at 25°C

- High Chemical Resistance: Stable in both acidic and alkaline environments

- Low Dielectric Loss: Favorable for microwave and RF applications

- Surface Quality: Polished to atomic-level smoothness (Ra < 5 Å)

- High Purity: Low levels of impurities ensuring consistent and repeatable results

-

- Excellent lattice matching for oxide thin films

- Wide transparency from UV to IR regions (0.3μm–6μm)

- High thermal conductivity and melting point (2852°C)

- Chemically inert to most acids and alkalis

- Low dielectric constant (ε ≈ 9.65 at 1MHz)

-

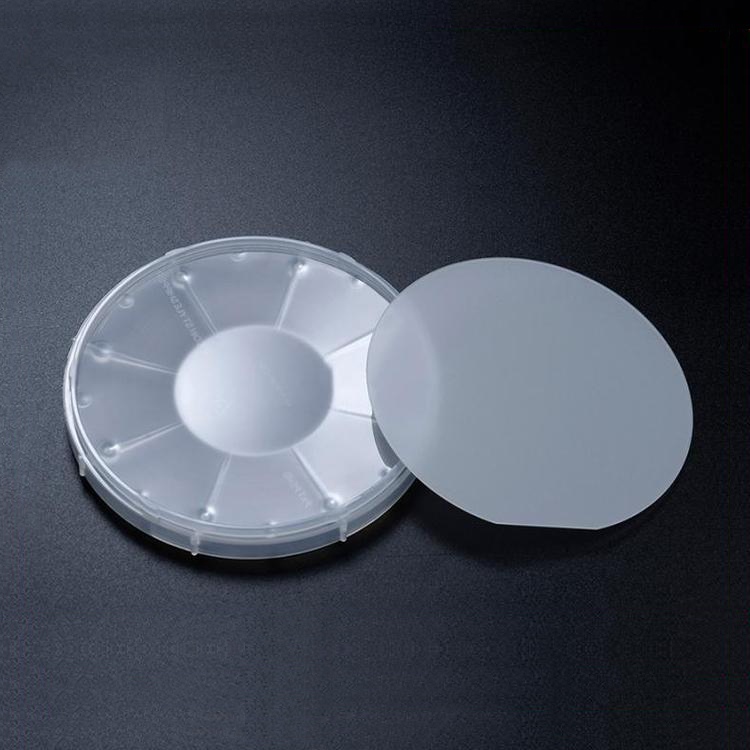

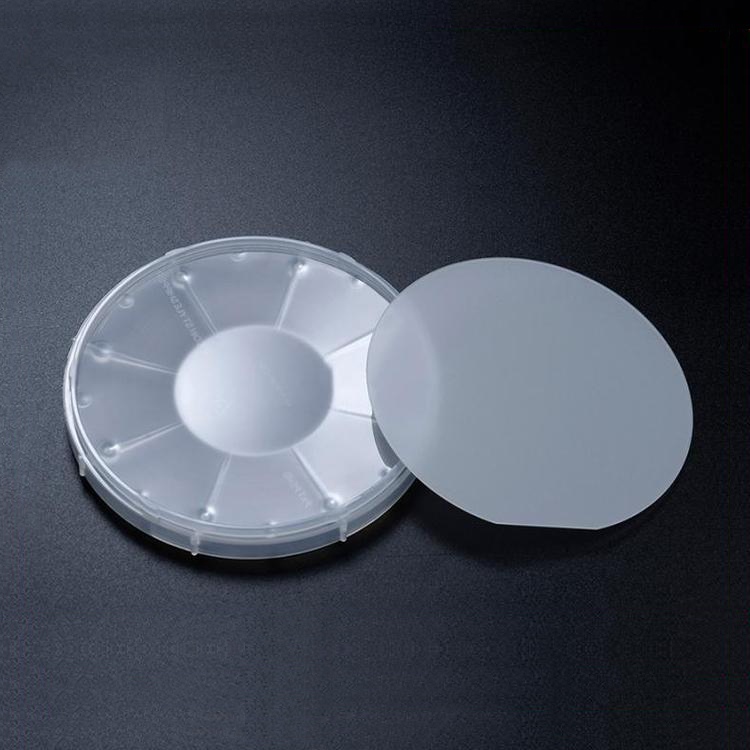

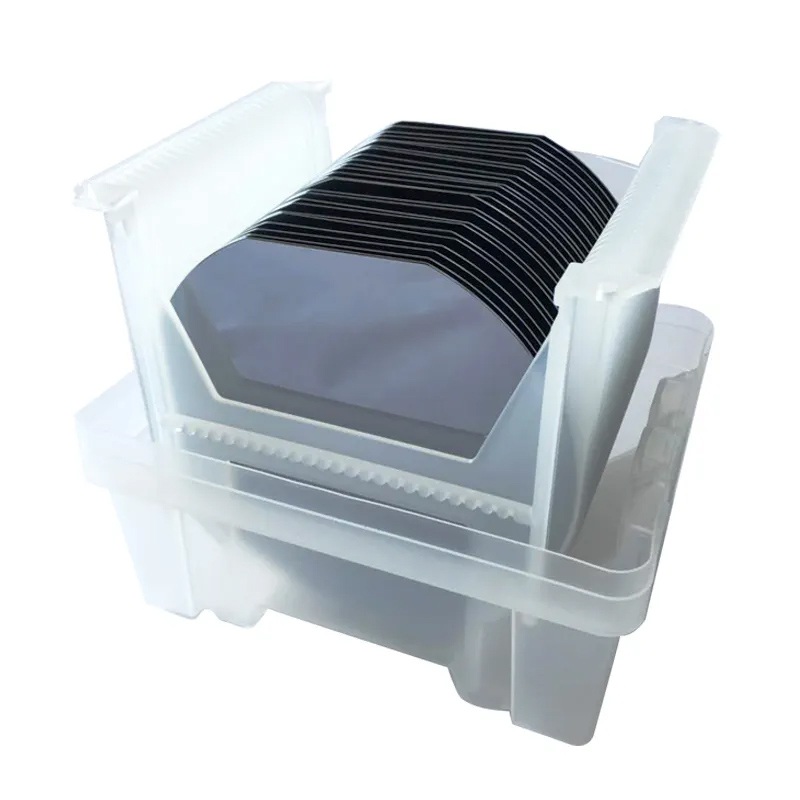

- Diameter Choices: 2″ to 12″ (or custom sizes).

- Doping Concentration: Custom doping profiles for N-type and P-type wafers.

- Thickness Variability: From ultra-thin wafers to thick substrates.

- Crystal Orientation: Standard orientations include <100>, <111>, <110>, with custom orientations available.

- Flat & Edge Treatment: Rounded, chamfered, or custom edge profiles.

- Surface Finishing:

- SSP (Single-Side Polished) or DSP (Double-Side Polished).

- Oxide coating, etched surfaces, or epitaxial layers upon request.