Showing 1–12 of 33 results

-

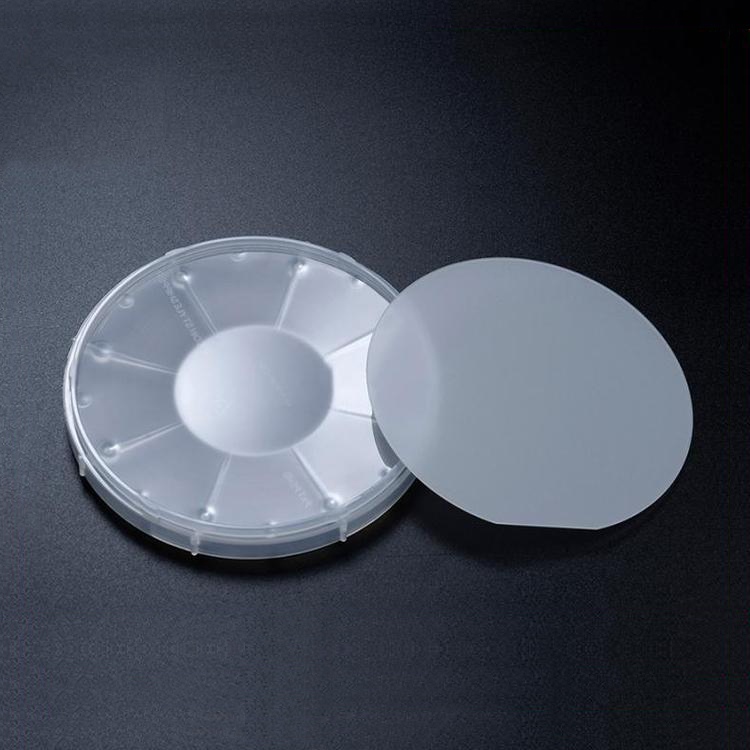

- Excellent Surface Flatness: Atomically smooth surfaces after mechanical and chemical polishing

- Superior Purity: Available with purity grades ≥ 99.999% (5N) for high-precision applications

- Outstanding Thermal Conductivity: ~235 W/m·K at 300K

- High Ductility and Malleability: Ideal for deformation and recrystallization studies

- Stable Oxide Layer: Natural formation of a thin Al₂O₃ protective layer

- Corrosion Resistance: Suitable for atmospheric and mild chemical environments

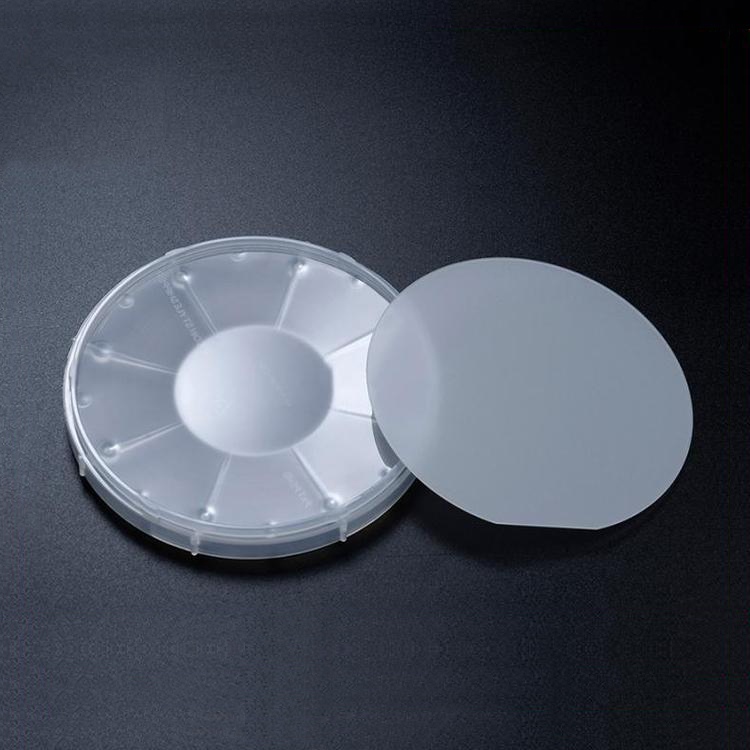

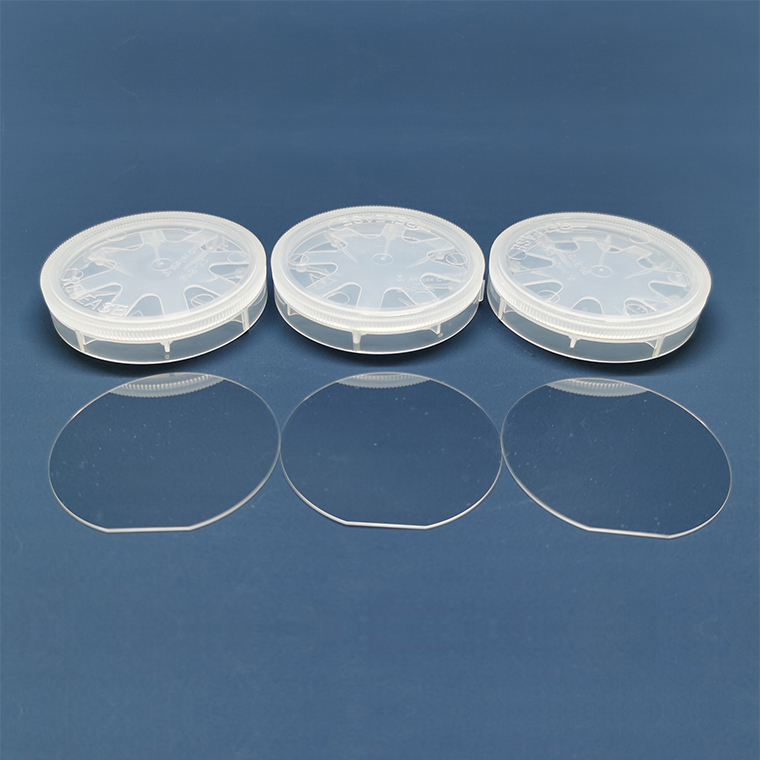

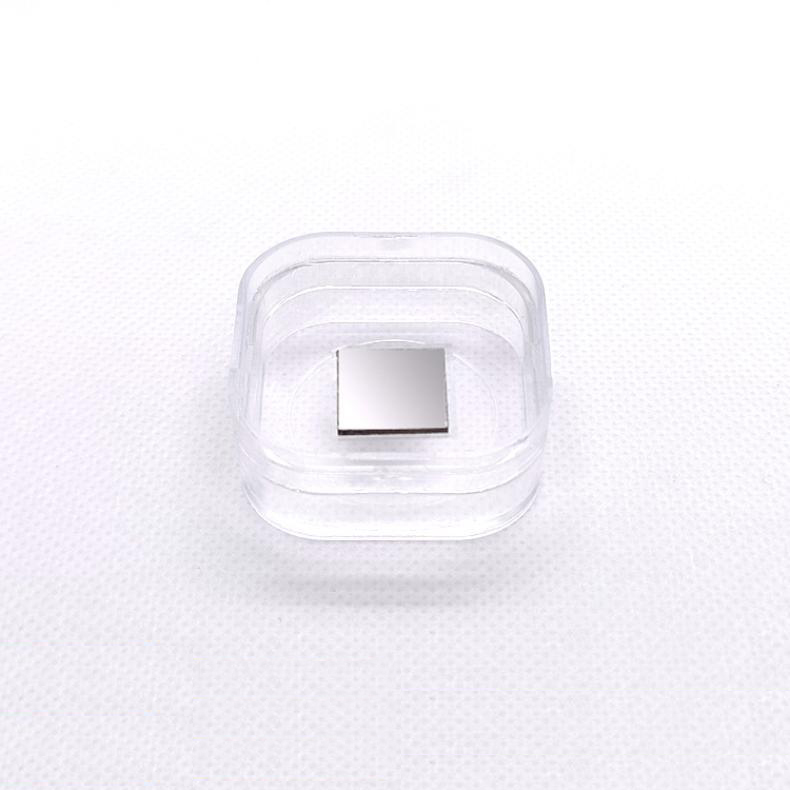

- Customizable Size and Thickness: From small squares to large diameter disks

-

- Ultra-High Thermal Conductivity: Up to 285 W/m·K, comparable to diamond.

- Wide Bandgap: ~6.2 eV, ideal for UV optoelectronic devices.

- High Electrical Resistivity: Excellent insulation properties.

- Superior Chemical and Thermal Stability: Suitable for harsh environments.

- Low Dielectric Constant and Loss: Enables high-frequency applications.

- High Mechanical Strength and Hardness: Durable under mechanical stress.

- Perfect Lattice Match for GaN: Supports high-quality epitaxial GaN growth.

-

- Ultra-Wide Transmission Range (DUV to IR): 150 nm to 12–15 μm.

- Low Refractive Index: Minimizes reflection losses without extensive coatings.

- High Radiation Resistance: Suitable for high-radiation environments such as space and nuclear detectors.

- Low Dispersion: Excellent for optical systems requiring minimal chromatic aberration.

- Good Mechanical Properties: Higher fracture toughness compared to other fluoride crystals.

- Low Absorption and High Optical Quality: Especially critical in high-resolution spectroscopic systems.

- Compatibility with High-Energy Lasers: Due to high laser-induced damage threshold.

- Ease of Cleaving and Processing: Supports cost-effective manufacturing.

- Stable Physical and Chemical Properties: Good moisture resistance compared to other fluorides.

-

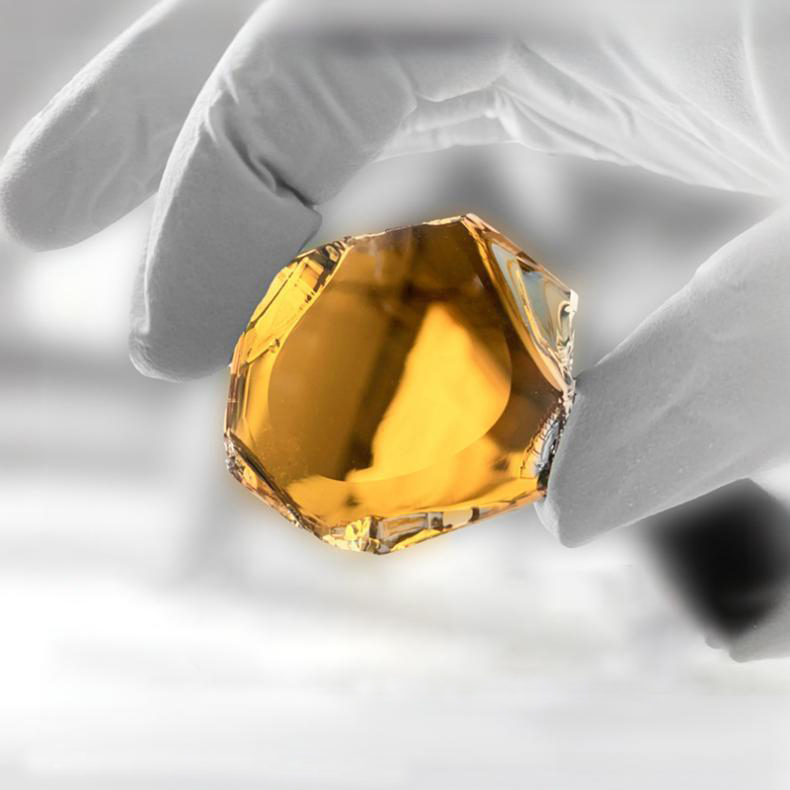

- Ferroelectric behavior with spontaneous polarization

- Extremely high dielectric constant (up to thousands near Curie temperature)

- Piezoelectric and electro-optic effects

- Cubic structure at high temperature, tetragonal below Curie temperature (~120°C)

- Suitable for integration with other perovskite materials

- Atomically smooth surfaces achievable for epitaxy

-

- High Electro-optic and Photorefractive Properties: Suitable for real-time holography and optical data processing.

- Cubic Crystal Structure: Isotropic optical properties, facilitating easier device integration.

- High Photoconductivity: Enhances photorefractive response and device efficiency.

- Broad Transparency Range: From ~450 nm to 7000 nm.

- High Optical Damage Threshold: Suitable for high-intensity light exposure.

- Excellent Thermal and Chemical Stability: Reliable under varied operating conditions.

-

- Direct Bandgap Semiconductor: Efficient absorption and emission of light; excellent for photovoltaic and photonic applications.

- High Optical Absorption: Especially in the visible spectrum.

- Strong Nonlinear Optical Effects: Useful for laser frequency conversion and optical modulation.

- Broad Transmission Range: From visible to near-infrared (0.7–3 μm).

- Low Defect Density: Ensures better carrier mobility and device performance.

- Good Chemical Stability: Under controlled conditions, suitable for device encapsulation.

- High Quantum Efficiency: Critical for optoelectronic device performance.

- High Dielectric Constant: Beneficial for high-frequency electronic applications.

-

- Wide Direct Bandgap: ~2.42 eV at room temperature, ideal for visible light applications.

- High Optical Transparency: Strong transmission from UV to visible spectral range.

- Excellent Epitaxial Compatibility: Ideal lattice matching with other II-VI semiconductor materials.

- Good Electrical Properties: Suitable for device applications in photodetection and photovoltaic fields.

- High Crystallinity: Available with low defect densities and precise orientation control.

-

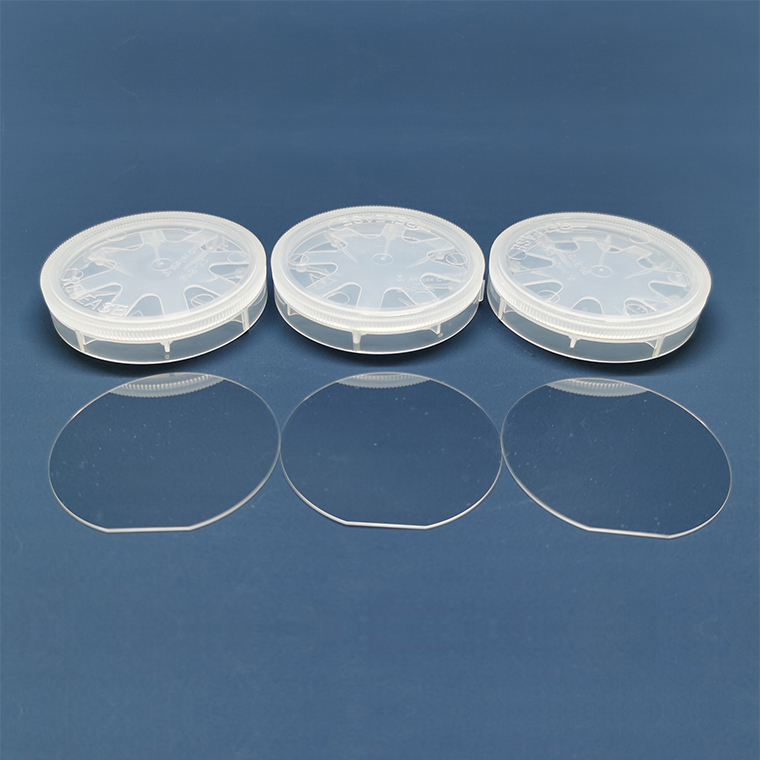

- Wide Transmission Range (125 nm–10 μm): Ideal for deep UV, visible, and IR applications.

- Low Refractive Index: Reduces need for anti-reflective coatings.

- Minimal Birefringence: Suitable for precision optical systems.

- High Laser Damage Threshold: Critical for high-power laser optics.

- Excellent Chemical Inertness: Resistant to water, many acids, and most solvents.

- Thermal and Mechanical Stability: Supports use in demanding environments.

- Low Absorption in UV and IR: Maximizes optical throughput.

- Compatibility with Epitaxial Growth: Suitable for specialized semiconductor processes (e.g., GaN on CaF₂ substrates).

- Low Scattering and High Surface Quality: Essential for high-resolution optical systems.

-

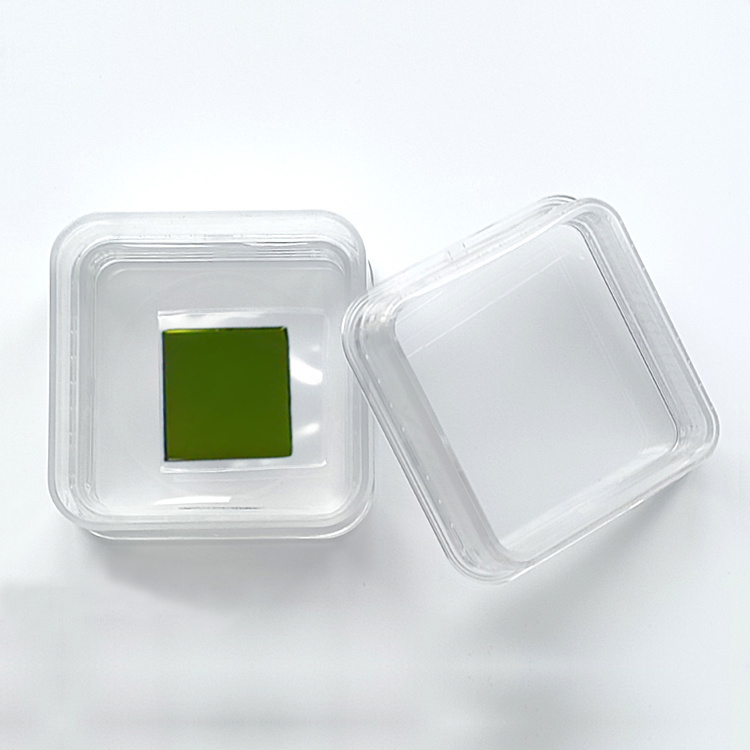

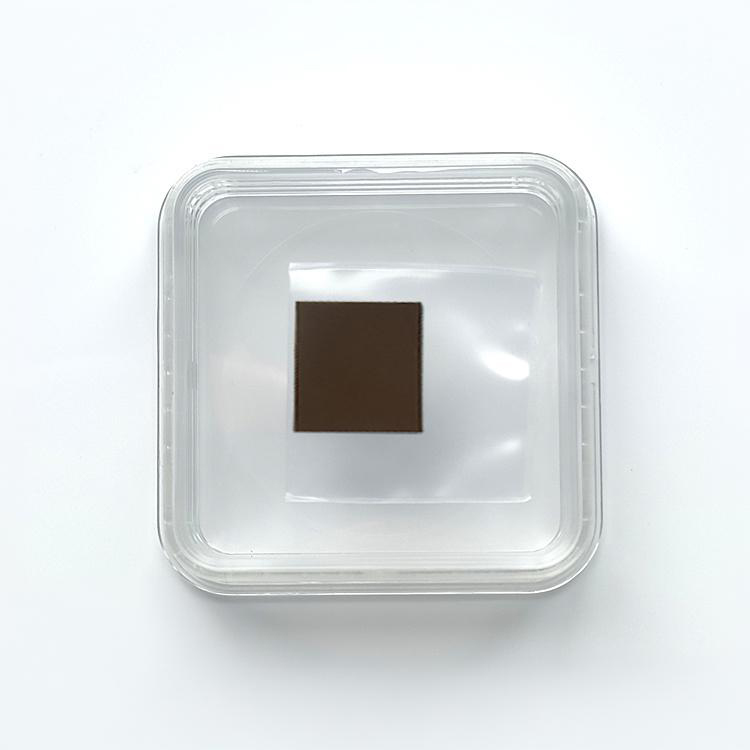

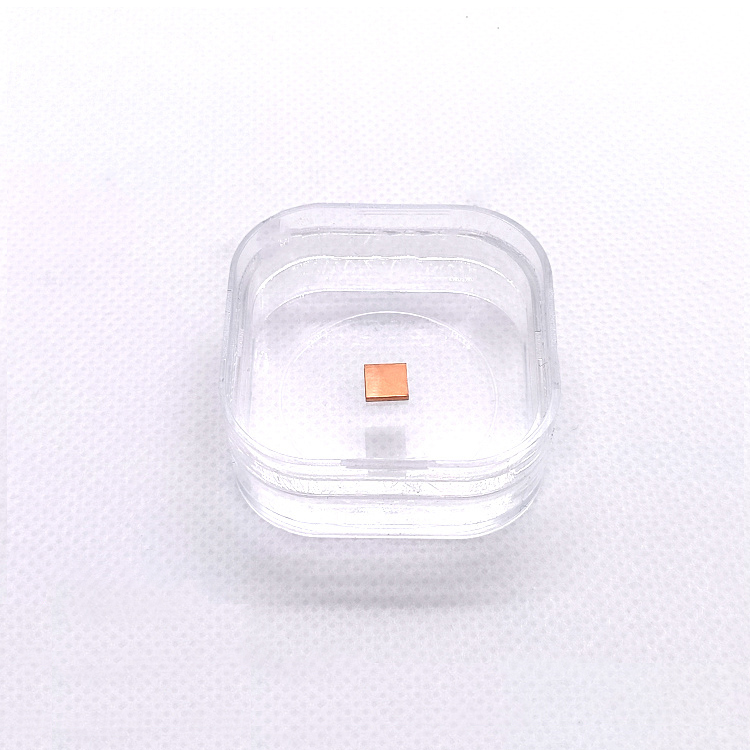

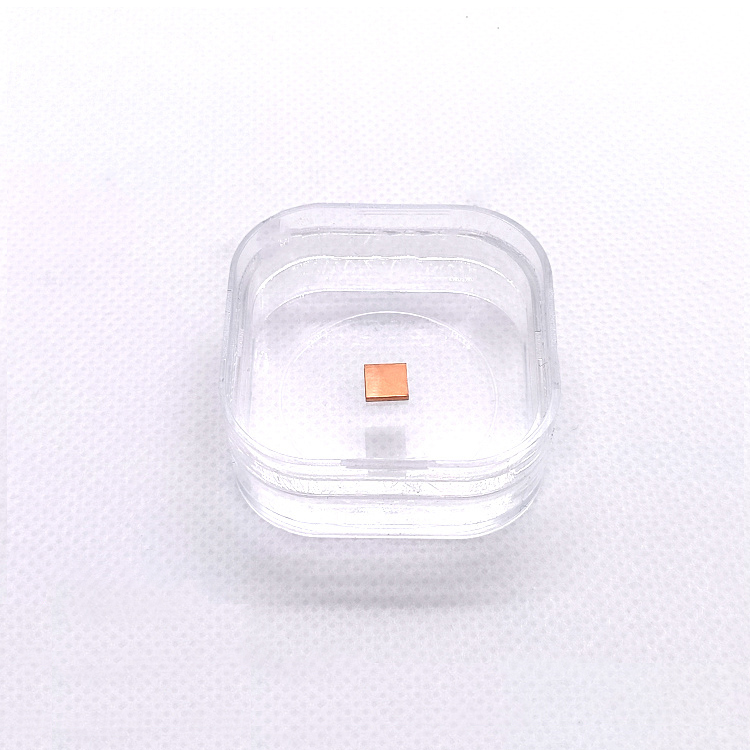

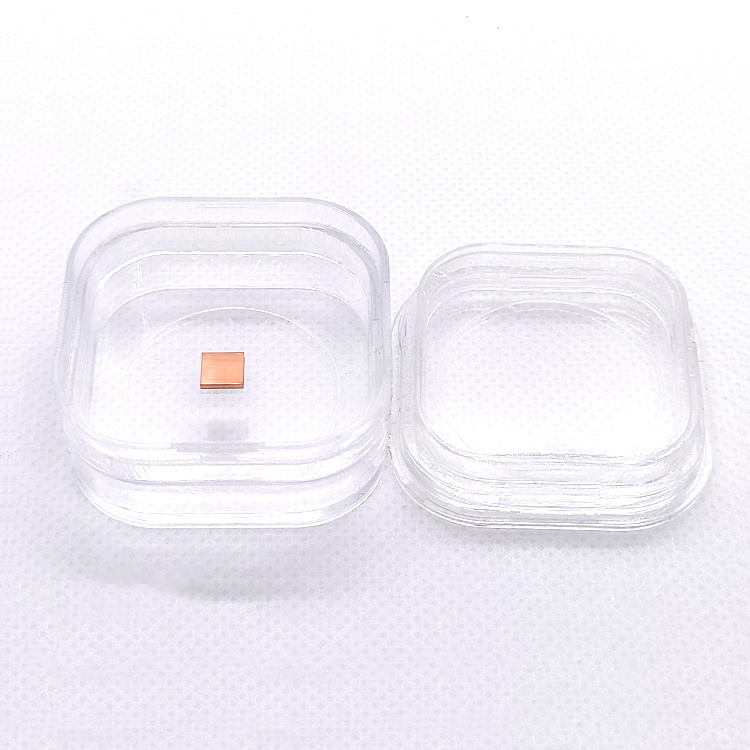

- High Electrical Conductivity: One of the highest among metals (~5.96×10⁷ S/m at 20°C)

- Excellent Thermal Conductivity: ~400 W/m·K

- Surface Smoothness: Atomically flat surfaces achievable after polishing

- Superior Purity Levels: Available in 99.999% (5N) or higher grades

- Stable Crystallographic Surface: Ideal for reproducible surface-sensitive experiments

- Low Surface Roughness: Ra < 5 Å achievable for polished samples

- Strong Corrosion Resistance: Protective native oxide layer forms naturally under ambient conditions

- Easily Customizable: Wide range of sizes, thicknesses, and orientations available

-

- Exceptional Electro-Optic Performance: Extremely high electro-optic coefficients enabling high-speed modulation and tunable devices.

- High Dielectric Constant: Useful for applications in capacitors and tunable microwave devices.

- Wide Transparency Range: Optical transmission from near-UV (~400 nm) to mid-IR (~5.5 μm).

- Tunable Refractive Index: Ability to electrically modulate optical properties.

- Low Optical Absorption: High transmission and low loss across the IR and visible spectrum.

- Precise Composition Control: Customizable Nb/Ta ratios (x values) to tailor ferroelectric and optical properties.

- Good Chemical Stability: Suitable for long-term operation in standard laboratory environments.

-

- Excellent Crystal Quality: Low dislocation density, high structural perfection.

- Ideal Lattice Match: Close lattice parameters with materials like YBCO, LSMO, PZT, and other perovskite oxides.

- High Thermal Stability: Suitable for high-temperature thin film deposition processes.

- High Dielectric Constant: Beneficial for microwave devices and tunable capacitors.

- Low Dielectric Loss: Ensures superior performance at high frequencies.

- Chemical Stability: Strong resistance to acids and bases.

- Atomically Smooth Surface: Achieved through advanced polishing and chemical etching processes.

-

- High Thermal Stability: Excellent performance under high temperatures up to 1500°C.

- Wide Bandgap: Enables use in deep UV and high-power electronic applications.

- Superior Mechanical Strength: Resists thermal shock and mechanical stress.

- Excellent Lattice Match: Ideal substrate for GaN, AlN, ZnO, and other oxide semiconductor epitaxial growth.

- Low Dielectric Loss: Beneficial for microwave and RF device applications.

- Chemical Inertness: High resistance to acids, alkalis, and environmental degradation.

- Smooth, Defect-Free Surface: Essential for high-yield epitaxial growth and thin-film deposition.