Showing 13–24 of 42 results

-

- High Strength-to-Weight Ratio: Combines the lightweight benefits of aluminum with the strength of iron.

- Thermal Stability: Resistant to high temperatures, making it ideal for demanding environments.

- Corrosion Resistance: Excellent performance in corrosive conditions.

- Customizable Particle Sizes: Suitable for diverse manufacturing processes.

- High Purity: Ensures consistent quality and performance.

- Excellent Alloying Properties: Compatible with various manufacturing techniques like powder metallurgy and additive manufacturing.

-

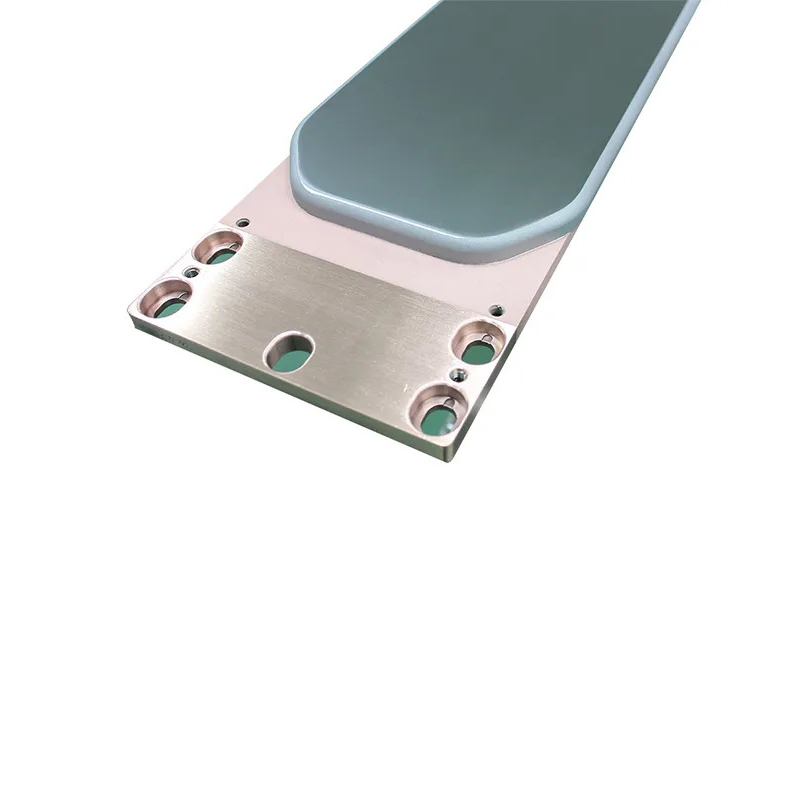

- High Thermal Conductivity: AlN offers one of the highest thermal conductivities among non-metals, which is vital for heat dissipation in high-power electronics and optoelectronics.

- Electrical Insulation: AlN is an excellent electrical insulator, making it suitable for electronic applications requiring electrical isolation with effective thermal management.

- Piezoelectric Properties: AlN exhibits strong piezoelectric properties, making it ideal for use in sensors, actuators, and acoustic wave devices.

- High Hardness and Durability: AlN films are mechanically robust, offering good wear resistance and durability for applications in harsh environments.

- Good Chemical Stability: AlN is resistant to many chemicals and environmental conditions, ensuring longevity in demanding applications.

-

- High Thermal Conductivity: Up to 180 W/m·K, ideal for heat dissipation in electronic devices.

- Excellent Electrical Insulation: High resistivity, suitable for high-voltage applications.

- Low Thermal Expansion: Matches well with silicon, reducing thermal stress in electronic assemblies.

- Chemical Stability: Resistant to chemical corrosion, even at high temperatures.

- Wide Applicability: Compatible with a variety of processing methods, including sintering and powder metallurgy.

- Customizable Particle Sizes: Available in nano-scale and micro-scale particle sizes to meet specific requirements.

-

- Excellent Electrical Conductivity: AlSi alloys offer good electrical conductivity, making them ideal for interconnect layers and conductive films in electronic devices.

- Thermal Stability: AlSi films exhibit high thermal stability, ensuring reliable performance in high-temperature environments, such as semiconductor processing.

- Prevention of Electromigration: The addition of silicon to aluminum helps mitigate electromigration, improving the longevity and reliability of electronic components.

- Corrosion Resistance: AlSi alloys have good resistance to oxidation and corrosion, contributing to the durability of thin films in harsh operating conditions.

- Lightweight and Strong: The lightweight nature of aluminum, combined with the added strength from silicon, makes AlSi alloys versatile in applications requiring both durability and reduced weight.

-

- Electrical Conductivity: The presence of aluminum and copper in the alloy enhances the electrical conductivity of the deposited thin films, making it ideal for semiconductor and electronic applications.

- Thermal Stability: AlSiCu alloy films exhibit excellent thermal performance, ensuring stability in high-temperature environments like semiconductor fabrication and automotive electronics.

- Mechanical Strength: Silicon contributes to the mechanical durability of the alloy, providing resistance to wear and cracking in thin films, which is essential in demanding applications.

- Corrosion Resistance: The alloy offers good resistance to corrosion, ensuring longevity in exposed environments, such as automotive electronics and solar cells.

- Customizable Size and Shape: AlSiCu sputtering targets can be produced in various forms, including discs, plates, and custom shapes, to suit different PVD systems and specific requirements.

-

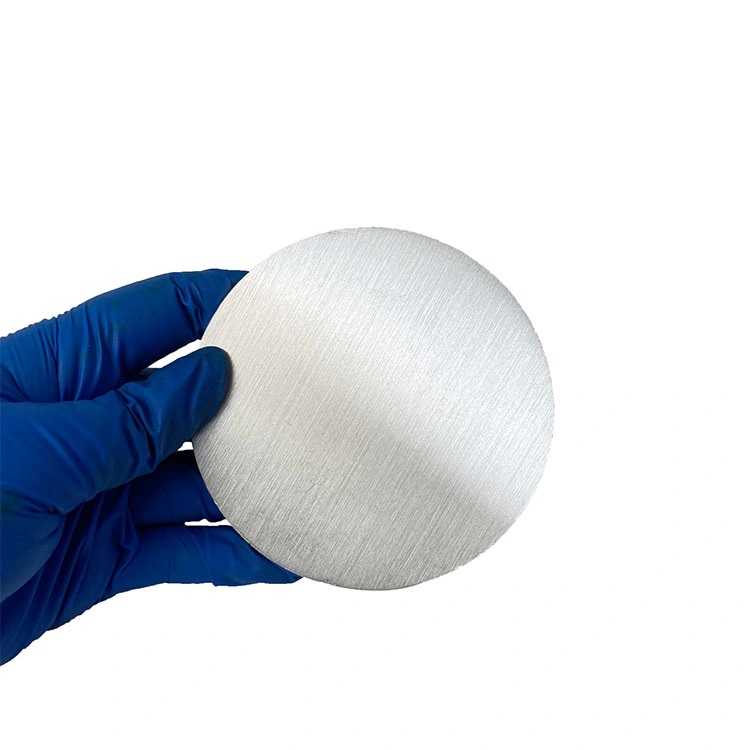

- Excellent Surface Flatness: Atomically smooth surfaces after mechanical and chemical polishing

- Superior Purity: Available with purity grades ≥ 99.999% (5N) for high-precision applications

- Outstanding Thermal Conductivity: ~235 W/m·K at 300K

- High Ductility and Malleability: Ideal for deformation and recrystallization studies

- Stable Oxide Layer: Natural formation of a thin Al₂O₃ protective layer

- Corrosion Resistance: Suitable for atmospheric and mild chemical environments

- Customizable Size and Thickness: From small squares to large diameter disks

-

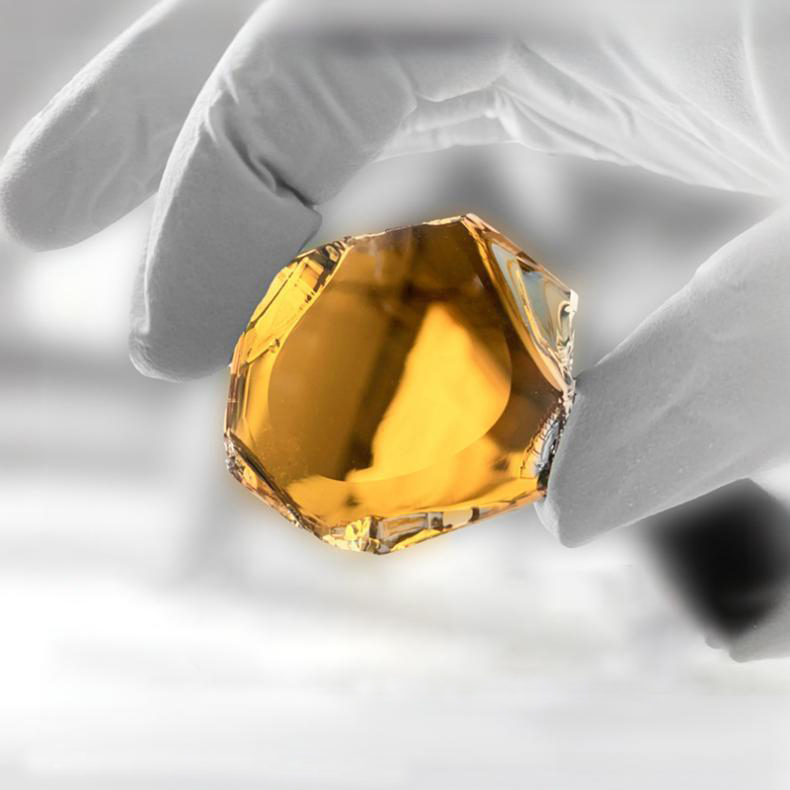

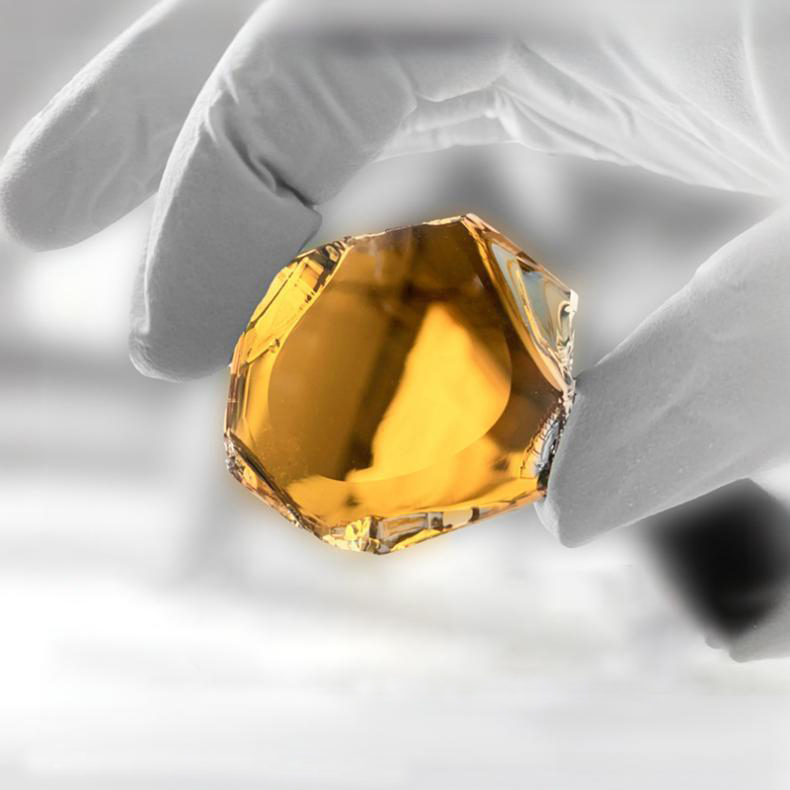

- Ultra-High Thermal Conductivity: Up to 285 W/m·K, comparable to diamond.

- Wide Bandgap: ~6.2 eV, ideal for UV optoelectronic devices.

- High Electrical Resistivity: Excellent insulation properties.

- Superior Chemical and Thermal Stability: Suitable for harsh environments.

- Low Dielectric Constant and Loss: Enables high-frequency applications.

- High Mechanical Strength and Hardness: Durable under mechanical stress.

- Perfect Lattice Match for GaN: Supports high-quality epitaxial GaN growth.

-

$51.00 – $96.00

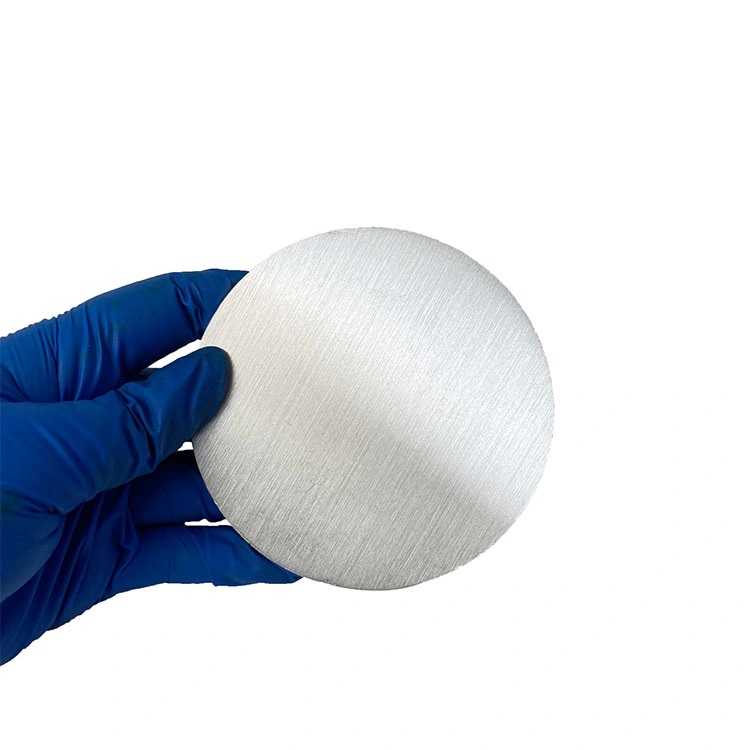

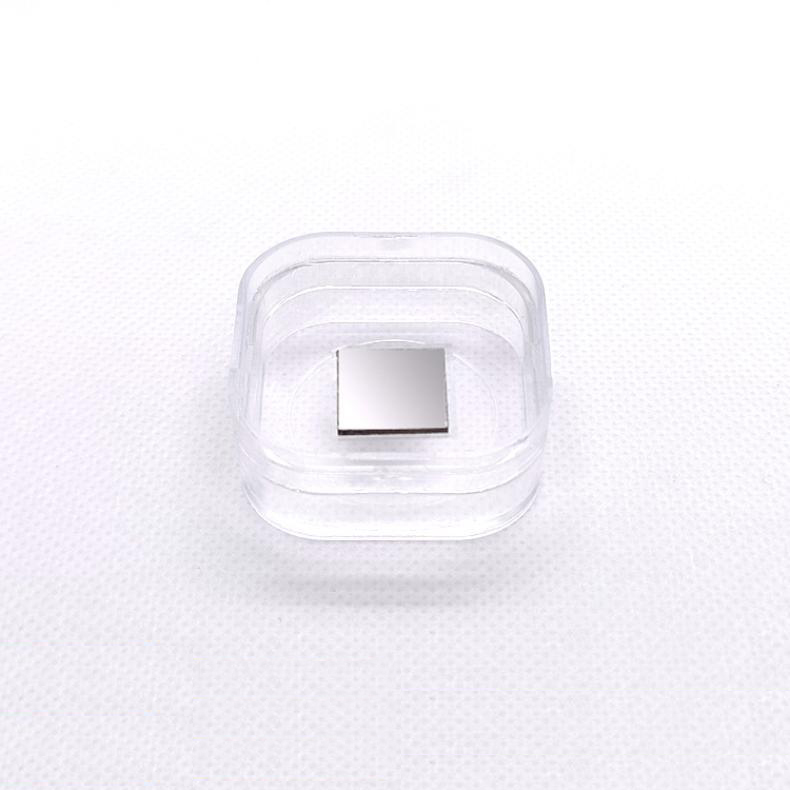

- Ultra-high purity 5N (99.999%) for superior film uniformity and low defect density.

- Excellent sputtering performance with stable deposition rates.

- Low impurity levels meeting research-grade and semiconductor-grade requirements.

- Standard sizes in stock for fast delivery.

- Fully customizable in purity, diameter, thickness, and shape.

-

$80.00 – $105.00

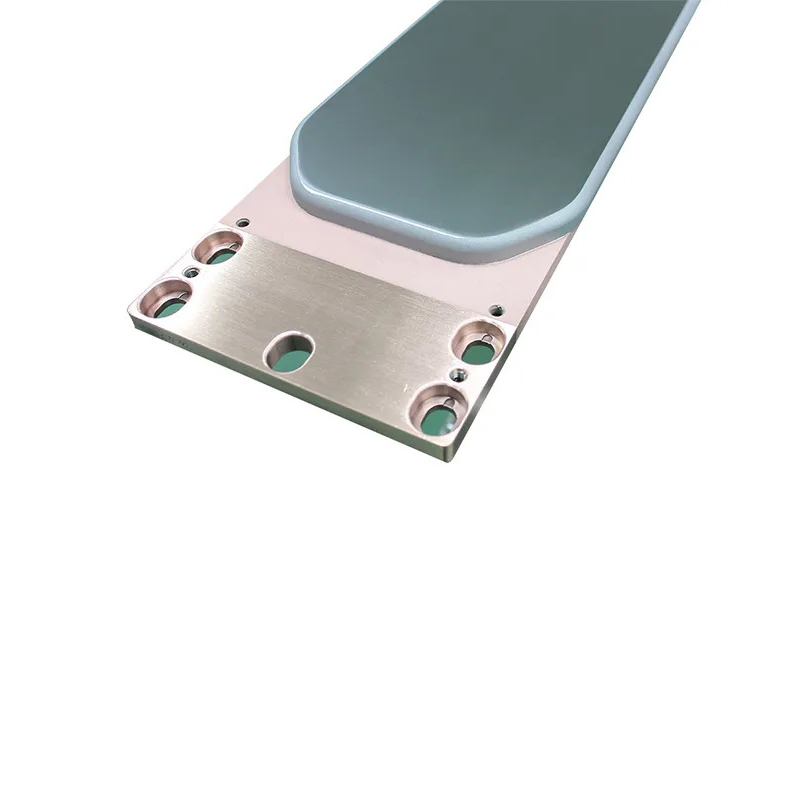

- Ultra-high purity 99.999% (5N), ensuring exceptional thin film quality and low impurity levels.

- Excellent sputtering performance, providing uniform film deposition and stable sputter rates.

- Multiple standard thickness options, including 6 mm with magnetic spacer for systems requiring enhanced magnetic coupling.

- High density and strong mechanical stability suitable for high-power sputtering systems.

- Customizable dimensions to match different sputtering equipment and process conditions.

-

- High Optical Transparency: AZO offers excellent transparency in the visible spectrum, making it ideal for applications requiring clear conductive films.

- Good Electrical Conductivity: Despite its transparency, AZO provides high electrical conductivity, which is critical in photovoltaic cells and touchscreens.

- Environmentally Friendly: Unlike ITO, AZO does not rely on scarce or expensive elements like indium, making it a more sustainable and cost-effective choice.

- Thermal and Chemical Stability: AZO films maintain stability under various temperature and environmental conditions, making them suitable for outdoor and industrial applications.

- Low Reflectivity: AZO films are known for their low reflectance, which is beneficial in display technologies to reduce glare and improve visibility.

-

$105.00 – $495.00

- High purity 99.99% (4N) for stable and clean industrial processing.

- Uniform granule size (1–3 mm) for consistent melting and reaction control.

- Excellent fluxing and melting properties, ideal for aluminum electrolysis.

- Low impurity content to ensure optimal performance in ceramics and abrasives.

- Good thermal and chemical stability suitable for high-temperature processes.

- Available in bulk quantities for industrial-scale consumption.

-

- Balanced Alloy Composition: Combines Fe, Co, Ni, Al, Cu, and Ti for superior performance.

- High Strength and Durability: Exceptional mechanical properties for demanding environments.

- Thermal Stability: Operates efficiently under extreme temperature conditions.

- Corrosion Resistance: Excellent resistance to oxidation and environmental wear.

- Magnetic Properties: Suitable for applications requiring magnetic performance.

- Customizable Particle Sizes: Available in nano and micro scales for various uses.