Showing 25–36 of 42 results

-

- Multi-Element Alloy: Balanced composition of Fe, Cu, Al, Cr, and Ni for enhanced properties.

- High Corrosion Resistance: Excellent resistance to oxidation and environmental degradation.

- Superior Mechanical Strength: Outstanding strength and durability for demanding applications.

- Thermal Stability: Maintains performance under high temperatures.

- Customizable Particle Sizes: Tailored for diverse manufacturing needs.

-

- High Strength-to-Weight Ratio: Combines durability with lightweight characteristics.

- Corrosion Resistance: Excellent performance in harsh environments.

- Thermal Stability: Maintains properties at elevated temperatures.

- Versatile Applications: Compatible with additive manufacturing, coatings, and traditional metallurgy.

- Customizable Composition: Tailored to meet specific project requirements.

-

- High-Temperature Strength: Maintains excellent mechanical properties at elevated temperatures.

- Oxidation Resistance: Outstanding performance in oxidative environments.

- Thermal Stability: Stable microstructure under cyclic thermal conditions.

- Corrosion Resistance: Effective against chemical and environmental corrosion.

- Process Compatibility: Suitable for 3D printing, thermal spraying, and conventional metallurgy.

-

- High-Temperature Strength: Retains superior mechanical properties at elevated temperatures, ensuring long-term reliability in harsh conditions.

- Oxidation and Corrosion Resistance: Exceptional resistance to oxidation and corrosion, even in extreme high-temperature environments.

- Excellent Castability: Ideal for casting applications due to its excellent moldability and resistance to thermal fatigue.

- Versatile Manufacturing: Compatible with additive manufacturing, powder metallurgy, and traditional casting methods.

- High-Precision Components: Suitable for applications that require high-performance parts with precision and minimal defects.

-

- High-Temperature Performance: Outstanding mechanical strength and creep resistance at elevated temperatures.

- Oxidation and Corrosion Resistance: Excellent resistance to oxidation and hot corrosion, ensuring long-term durability.

- Low Carbon Content: Reduces susceptibility to carbide precipitation, improving fatigue resistance.

- Exceptional Castability: Optimized for precision casting applications, with excellent mold-filling capabilities.

- Versatile Applications: Compatible with powder metallurgy and additive manufacturing for complex component production.

-

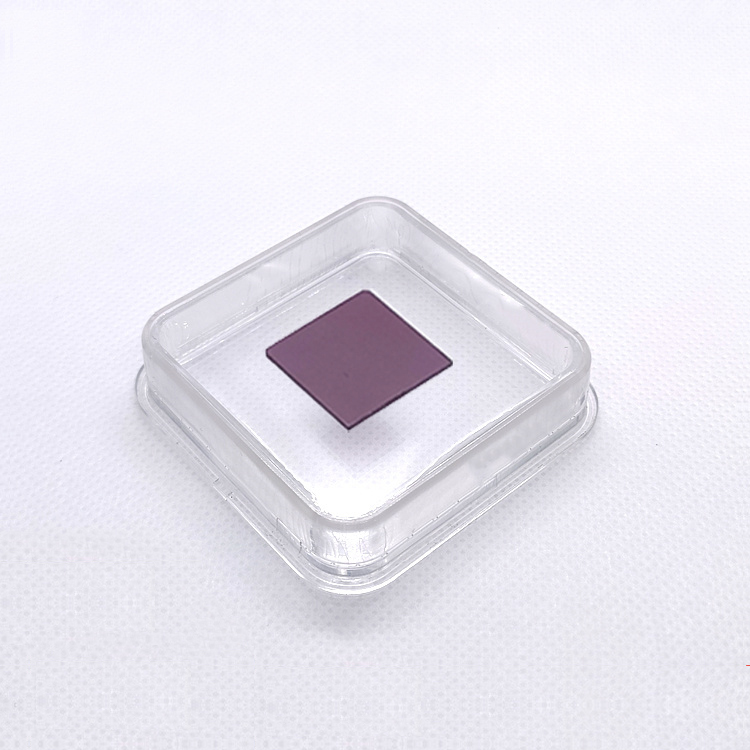

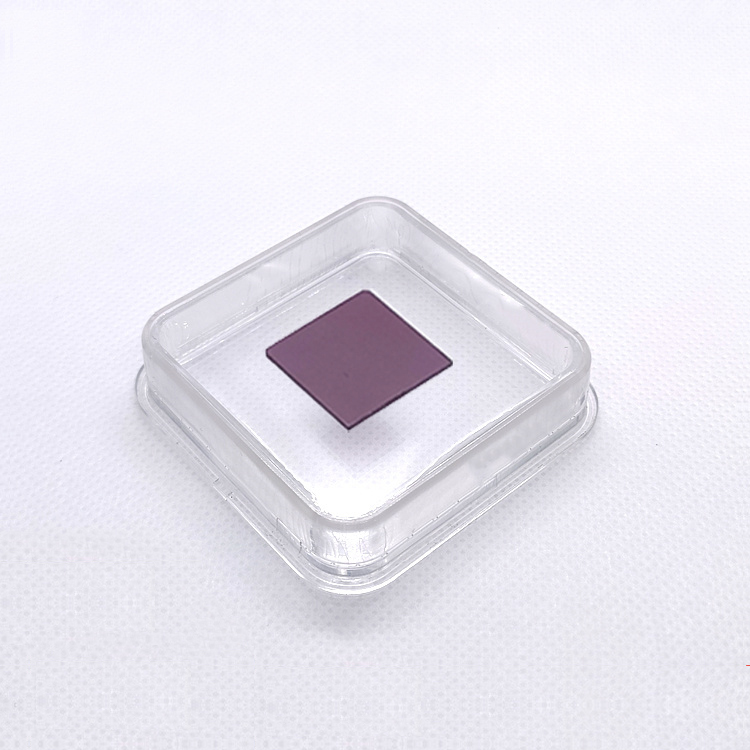

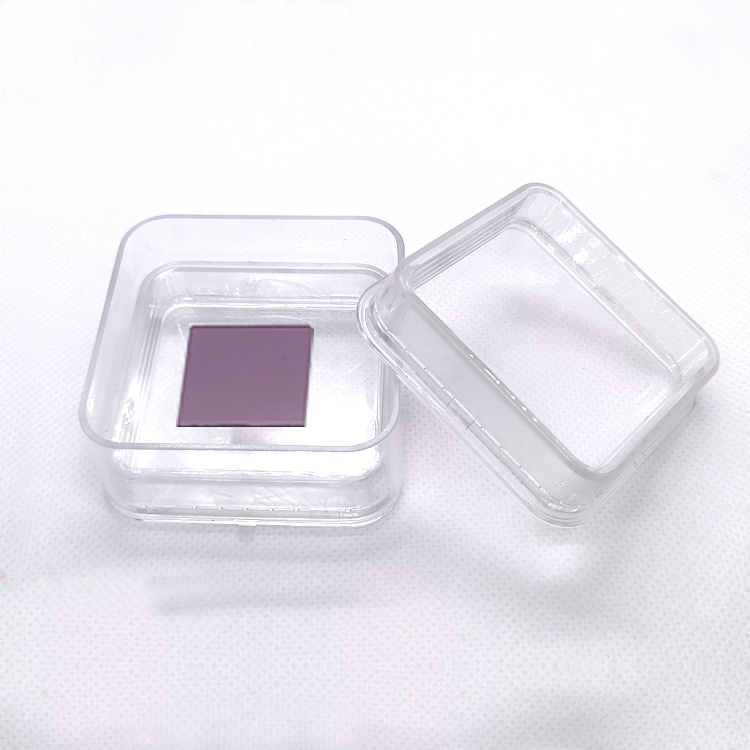

- High Dielectric Constant: LaAlO₃ has a high dielectric constant (k-value), which enhances its performance in capacitors and other high-k dielectric applications.

- Thermal Stability: LaAlO₃ exhibits excellent thermal stability, making it ideal for high-temperature processing and devices that operate in extreme environments.

- Structural Integrity: The perovskite structure of LaAlO₃ contributes to its high mechanical strength and chemical stability, ensuring long-lasting performance in demanding applications.

- Oxide Electronics: LaAlO₃ is widely used in complex oxide electronics due to its ability to form high-quality interfaces with other materials like SrTiO₃ and LaNiO₃.

-

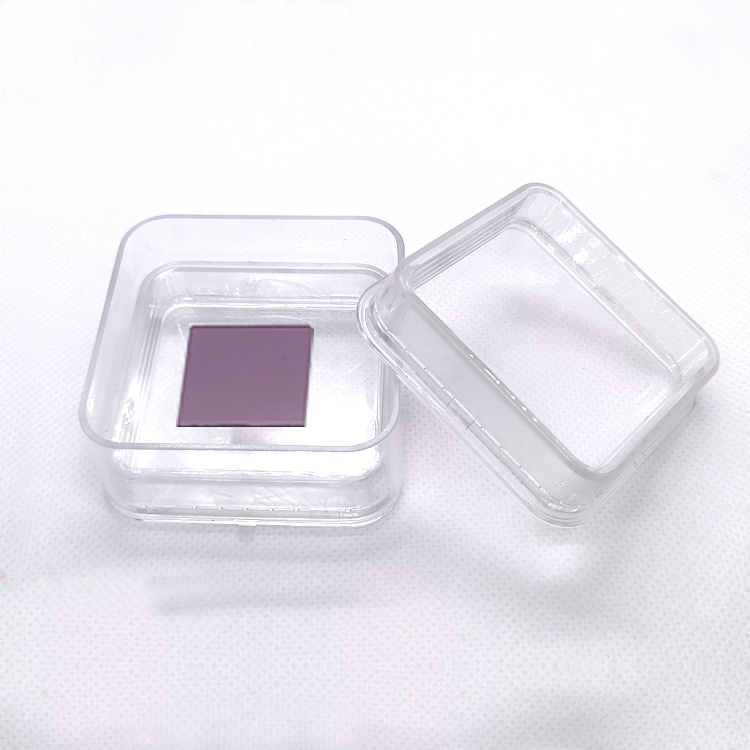

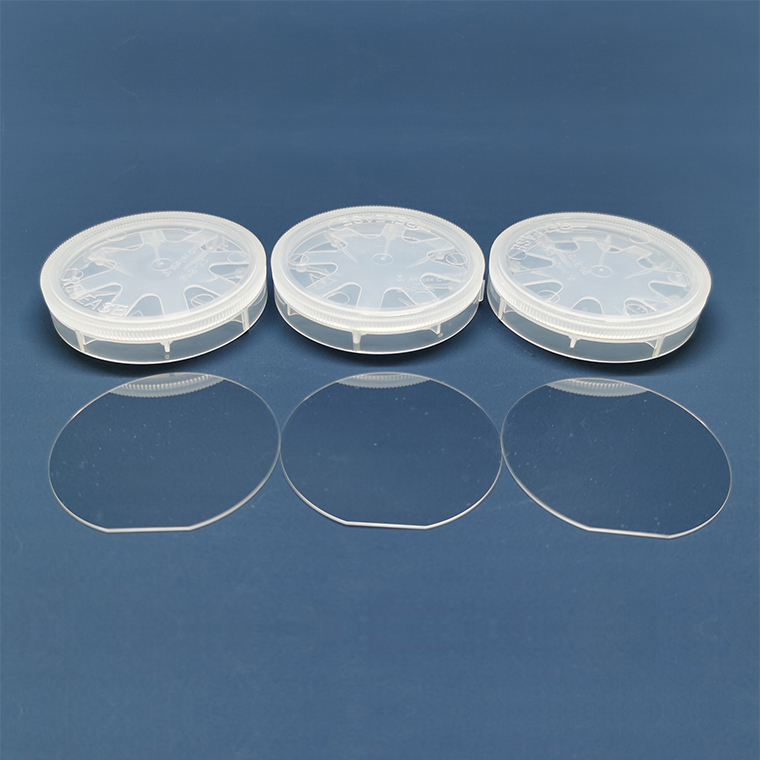

- Excellent Crystal Quality: Low dislocation density, high structural perfection.

- Ideal Lattice Match: Close lattice parameters with materials like YBCO, LSMO, PZT, and other perovskite oxides.

- High Thermal Stability: Suitable for high-temperature thin film deposition processes.

- High Dielectric Constant: Beneficial for microwave devices and tunable capacitors.

- Low Dielectric Loss: Ensures superior performance at high frequencies.

- Chemical Stability: Strong resistance to acids and bases.

- Atomically Smooth Surface: Achieved through advanced polishing and chemical etching processes.

-

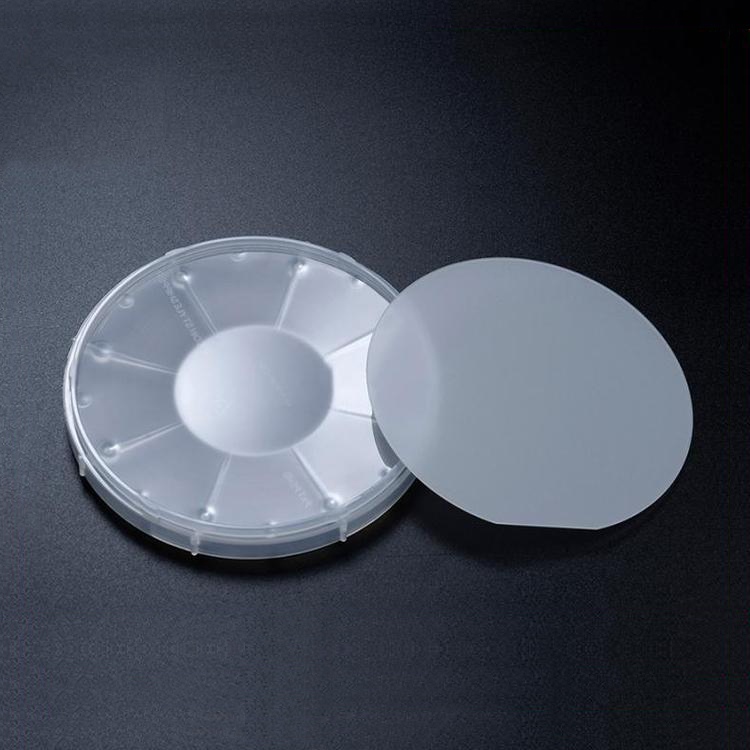

- High Thermal Stability: Excellent performance under high temperatures up to 1500°C.

- Wide Bandgap: Enables use in deep UV and high-power electronic applications.

- Superior Mechanical Strength: Resists thermal shock and mechanical stress.

- Excellent Lattice Match: Ideal substrate for GaN, AlN, ZnO, and other oxide semiconductor epitaxial growth.

- Low Dielectric Loss: Beneficial for microwave and RF device applications.

- Chemical Inertness: High resistance to acids, alkalis, and environmental degradation.

- Smooth, Defect-Free Surface: Essential for high-yield epitaxial growth and thin-film deposition.

-

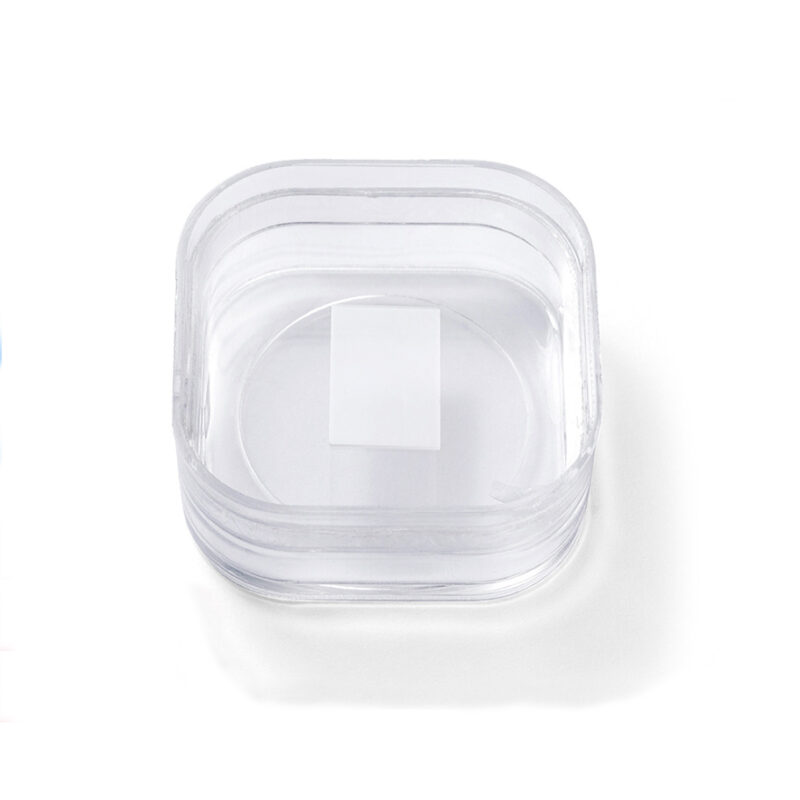

- Excellent Lattice Matching: Ideal match for many perovskite oxides such as YBCO, BST, and PZT

- High Thermal Stability: Maintains structural integrity under high temperatures

- Low Dielectric Loss: Suitable for microwave and dielectric applications

- High Crystallinity: Enables defect-free epitaxial film growth

- Good Mechanical Strength: Durable for various thin-film deposition processes

- Smooth Surface Finish: Atomic-level flatness for epitaxial growth

- High Chemical Stability: Resists degradation during processing

- Wide Application Range: Compatible with superconducting, ferroelectric, and oxide-based systems

-

- Excellent Thermal Stability: Suitable for high-temperature processing (melting point ~2135°C)

- Wide Optical Transmission: From 200 nm (UV) to 5000 nm (Mid-IR)

- Superior Mechanical Strength: High hardness and fracture toughness

- Low Thermal Expansion: 8.5 × 10⁻⁶ /°C at 25°C

- High Chemical Resistance: Stable in both acidic and alkaline environments

- Low Dielectric Loss: Favorable for microwave and RF applications

- Surface Quality: Polished to atomic-level smoothness (Ra < 5 Å)

- High Purity: Low levels of impurities ensuring consistent and repeatable results

-

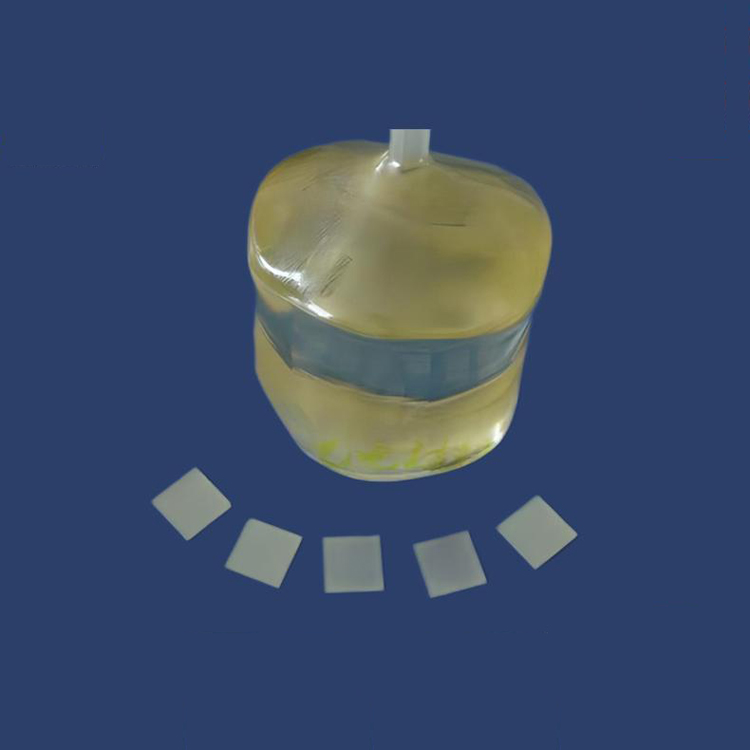

- High UV Transparency: Na₃AlF₆ is transparent in the UV and IR spectral regions, making it suitable for optical coatings in UV-sensitive applications.

- Good Adhesion: Forms thin films with excellent adhesion to a variety of substrates.

- Low Refractive Index: Offers a low refractive index, which is beneficial for anti-reflective coatings and optical interference filters.

- Corrosion Resistance: Provides a protective layer with good resistance to chemical and environmental factors.

-

- Excellent Thermal Stability: Maintains crystal integrity at high operating temperatures.

- Good Chemical Resistance: Resists degradation in acidic and basic environments.

- Low Lattice Mismatch: Ideal for the epitaxial growth of complex oxides and superconducting films.

- High Mechanical Strength: Reduces risk of cracking during processing and device operation.

- Superior Surface Quality: Supports high-quality thin film deposition.

- Perovskite-like Structure: Compatible with a broad range of oxide thin films.

- Stable Optical Properties: Suitable for use in optical communication and laser components.