Showing 37–42 of 42 results

-

- Extreme surface hardness (Mohs 9, second only to diamond)

- Wide optical transmission from 150 nm (UV) to 5.5 μm (MWIR)

- High thermal conductivity and thermal shock resistance

- Excellent chemical inertness against acids and alkalis

- High dielectric strength and electrical insulation properties

-

- Thermal Stability: Sr₃Al₂O₆ sputtering targets exhibit excellent thermal stability, making them suitable for high-temperature deposition processes.

- Durability: The material provides strong, durable films that are resistant to wear and tear, enhancing the longevity of devices.

- High Luminescent Properties: When doped with certain elements, it can act as a phosphorescent material, making it valuable in the display and lighting industries.

- Versatile Film Properties: It can produce films with excellent uniformity and precise thickness control in sputtering processes.

- Chemical Resistance: Sr₃Al₂O₆ is chemically stable, contributing to the robustness of coatings and films.

-

- Superior Strength-to-Weight Ratio: TC4 offers exceptional strength while maintaining a lightweight profile, making it ideal for demanding applications.

- Corrosion Resistance: Resistant to corrosion in various environments, particularly in harsh aerospace and marine conditions.

- Biocompatibility: Safe for medical and implant applications due to its non-toxic and biocompatible properties.

- Excellent Weldability: The alloy’s composition allows for good weldability, ensuring reliable performance in critical applications.

- High Durability: Resistant to wear and fatigue, making it suitable for long-lasting and high-performance products.

-

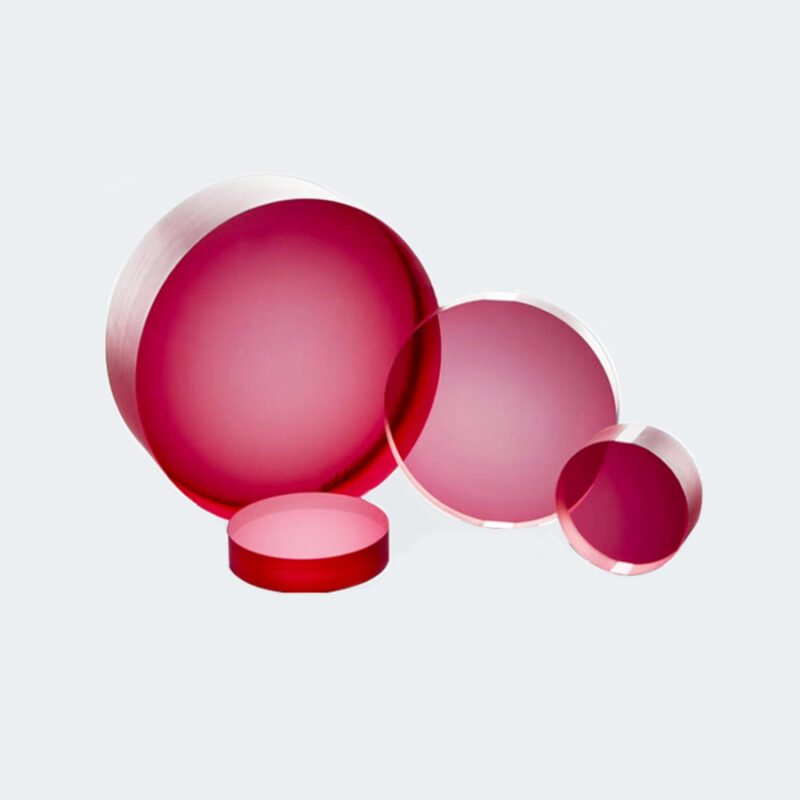

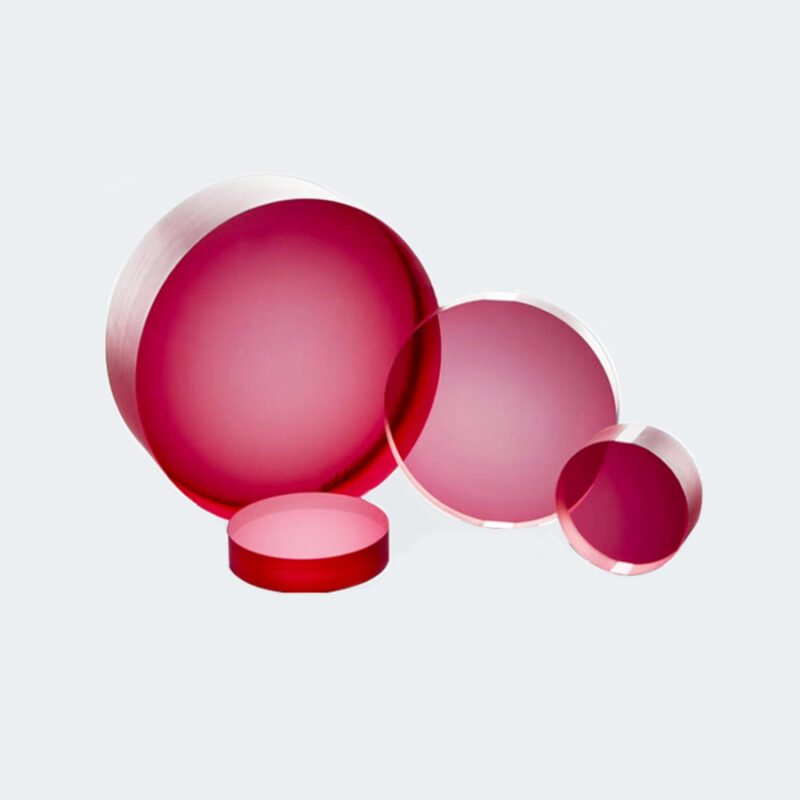

- Broad tunable laser output: 650–1100 nm

- Peak emission wavelength around 800 nm

- Wide absorption band: 400–600 nm (pumpable by 514–532 nm green lasers)

- Extremely broad gain bandwidth – ideal for femtosecond pulses

- High damage threshold and chemical stability

- Excellent thermal conductivity and optical quality

- Supports ultrashort pulse generation (<10 fs)

-

- High Strength-to-Weight Ratio: TiAl alloys combine the lightweight nature of aluminum with the strength of titanium, making them ideal for thin films in high-performance applications.

- Corrosion and Oxidation Resistance: TiAl films provide excellent resistance to corrosion and oxidation, ensuring durability and longevity in harsh environments.

- Thermal Stability: TiAl alloys can withstand high temperatures without losing mechanical properties, making them suitable for applications in high-temperature environments.

- Good Adhesion: TiAl thin films exhibit excellent adhesion to substrates, which is crucial for semiconductor and coating applications where film integrity is vital.

- Wear Resistance: The addition of titanium improves the hardness and wear resistance of TiAl coatings, contributing to extended tool life and enhanced component durability.

-

- High Thermal Stability: Suitable for high-temperature environments and laser operations.

- Excellent Mechanical Strength: Durable and resistant to cracking during processing.

- Broad Optical Transparency: Ranging from ~230 nm to 5.5 μm.

- Low Thermal Expansion Coefficient: Reduces thermal stress during device fabrication.

- High Refractive Index: Beneficial for optical and laser device efficiency.

- Good Chemical Resistance: Stable against most acids and alkalis under normal conditions.

- Low Dielectric Loss: Suitable for microwave and RF applications.

- Efficient Host Crystal: Ideal for rare-earth doping for laser crystals (e.g., Nd:YAP lasers).