Showing 1–12 of 23 results

-

- Soft Magnetic Properties: CoTaZr alloy offers excellent soft magnetic properties, including high permeability and low coercivity, making it suitable for data storage and magnetic sensor applications.

- Thermal Stability: The presence of tantalum in the alloy enhances its thermal stability, allowing it to maintain performance at elevated temperatures.

- Corrosion Resistance: The addition of zirconium contributes to improved corrosion resistance, making CoTaZr thin films durable in challenging environmental conditions, ensuring longevity in devices.

- High Saturation Magnetization: CoTaZr alloys provide high saturation magnetization, enabling efficient energy storage and transfer in magnetic thin films.

- Low Losses: The alloy exhibits low magnetic and electrical losses, making it ideal for applications requiring high efficiency, such as power electronics and transformers.

-

- High Magnetic Saturation: The FeCoTa alloy offers excellent magnetic properties, including high magnetic saturation and low coercivity, making it ideal for use in data storage devices and other applications requiring strong and stable magnetic fields.

- Thermal Stability: The addition of tantalum enhances the alloy’s thermal stability, allowing FeCoTa thin films to perform reliably in high-temperature environments, such as aerospace and power electronics.

- Wear Resistance: Tantalum in the alloy also contributes to increased wear resistance, ensuring that the thin films maintain their integrity under mechanical stress and prolonging their lifespan.

- Corrosion Resistance: The alloy exhibits good resistance to corrosion, making it suitable for applications in harsh or outdoor environments.

- Customizable Composition: The ratio of Fe, Co, and Ta can be adjusted to optimize magnetic and physical properties for specific applications.

-

- Corrosion Resistance: Outstanding resistance to oxidation, pitting, and crevice corrosion in harsh environments.

- High-Temperature Performance: Maintains mechanical properties and structural integrity at temperatures up to 980°C.

- Exceptional Strength: Offers superior tensile, fatigue, and creep-rupture properties.

- Weldability and Fabricability: Excellent compatibility with welding and additive manufacturing processes.

- Versatile Material: Suitable for applications requiring resistance to seawater, chemicals, and high heat.

-

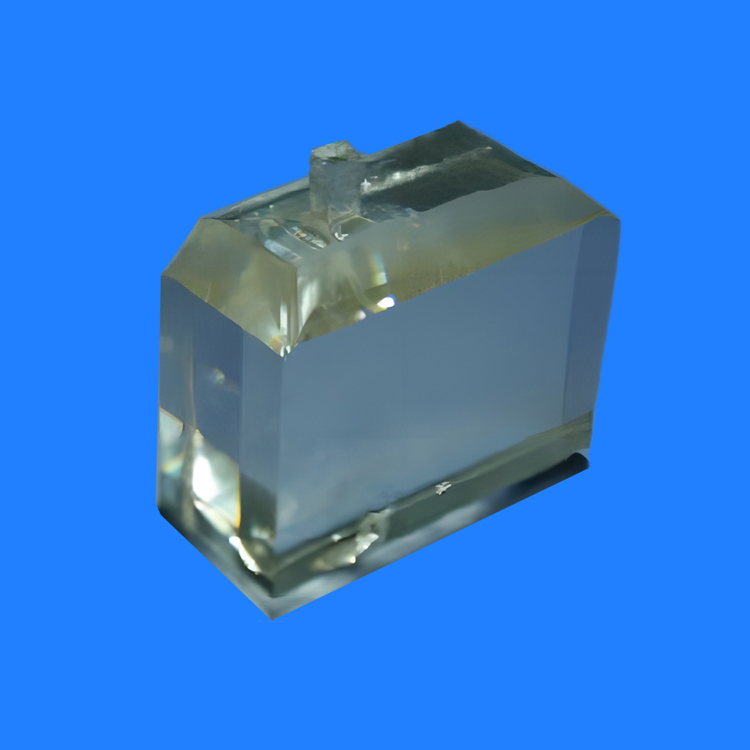

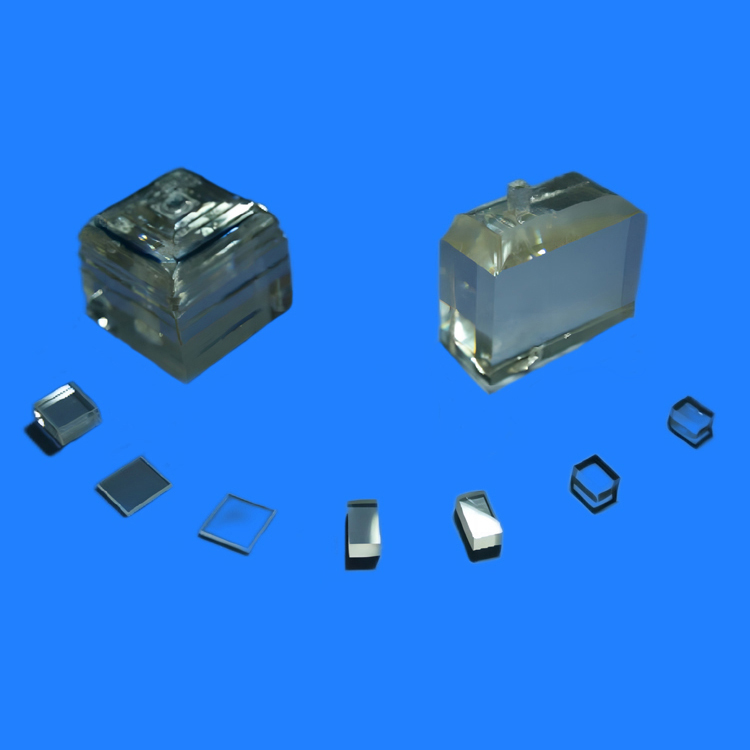

- Exceptional Electro-Optic Performance: Extremely high electro-optic coefficients enabling high-speed modulation and tunable devices.

- High Dielectric Constant: Useful for applications in capacitors and tunable microwave devices.

- Wide Transparency Range: Optical transmission from near-UV (~400 nm) to mid-IR (~5.5 μm).

- Tunable Refractive Index: Ability to electrically modulate optical properties.

- Low Optical Absorption: High transmission and low loss across the IR and visible spectrum.

- Precise Composition Control: Customizable Nb/Ta ratios (x values) to tailor ferroelectric and optical properties.

- Good Chemical Stability: Suitable for long-term operation in standard laboratory environments.

-

$1,285.00

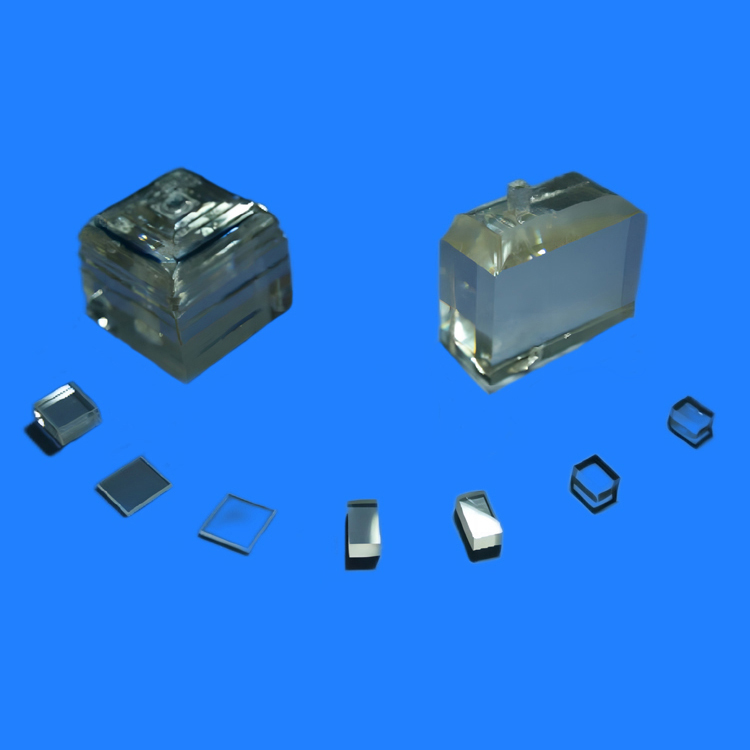

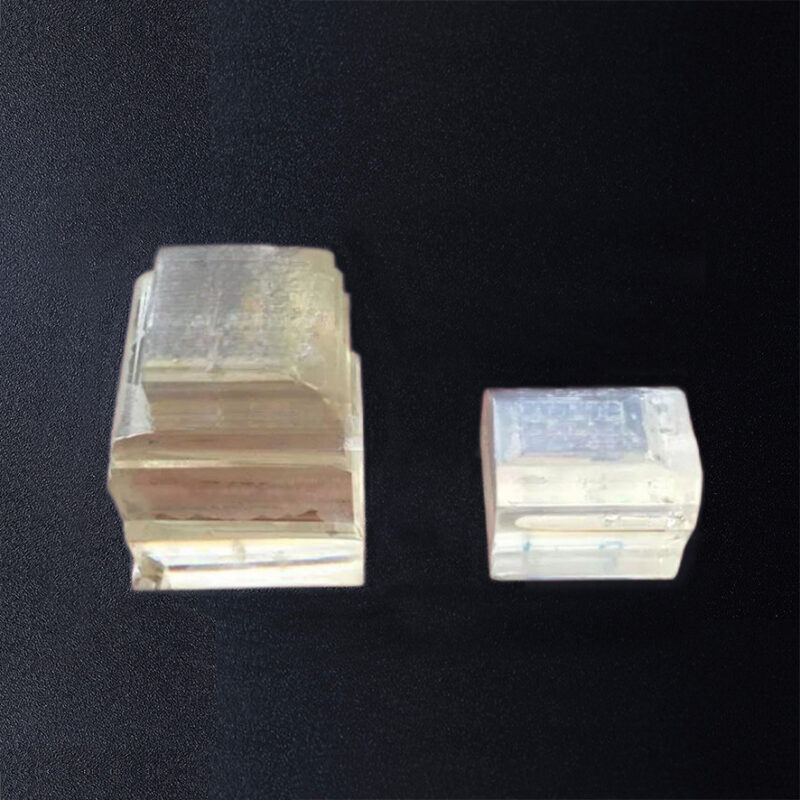

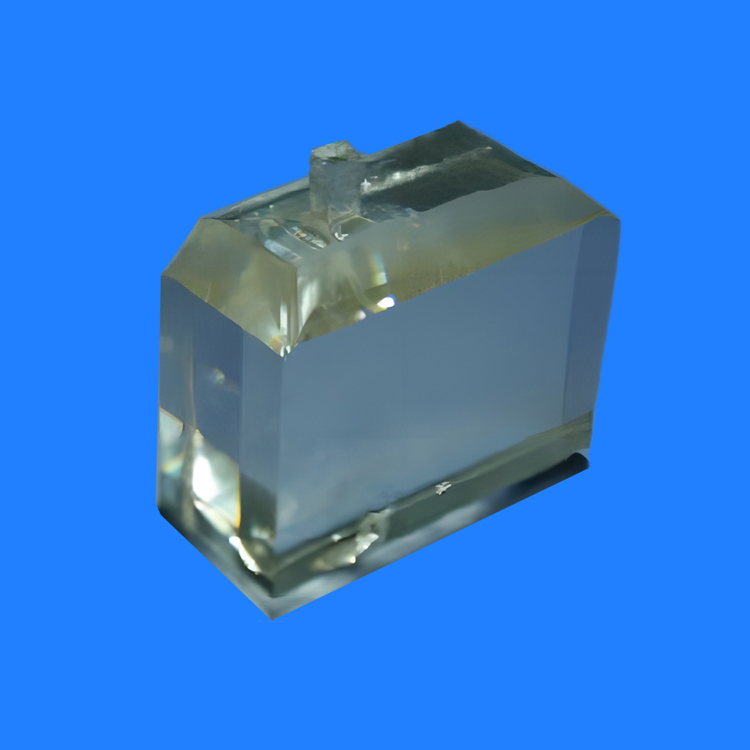

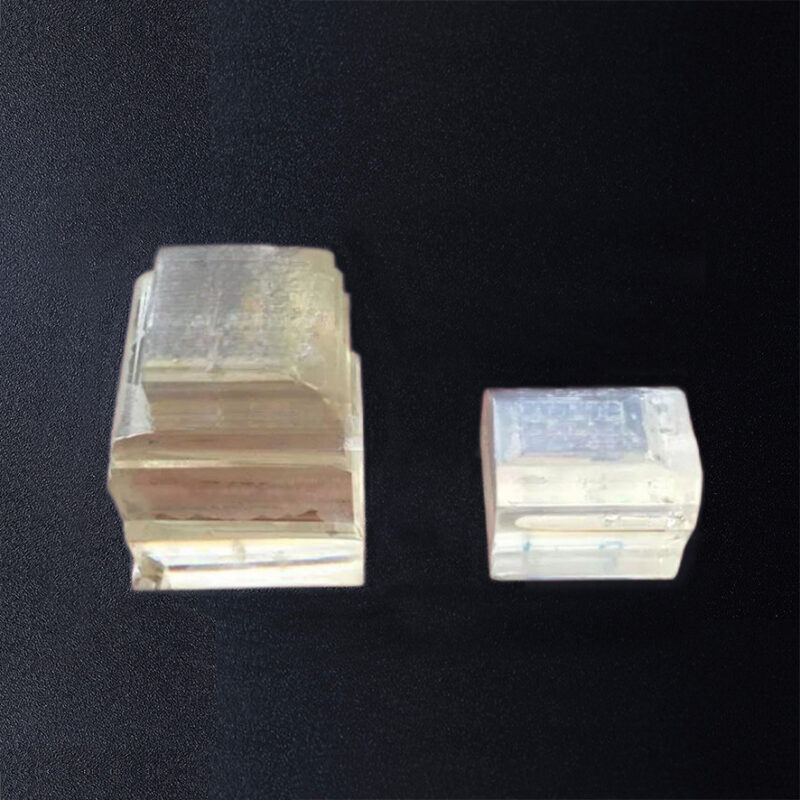

- Single crystal KTN with composition KTa₀.₅Nb₀.₅O₃

- <001> crystallographic orientation for optimal electro-optic performance

- Size: 10 × 10 × 0.5 mm

- High electro-optic coefficient (r33 ≈ 30–50 pm/V)

- Strong photorefractive effect

- Excellent dielectric tunability

- Wide optical transparency (~350 nm – 5500 nm)

- Low defect density and high optical uniformity

-

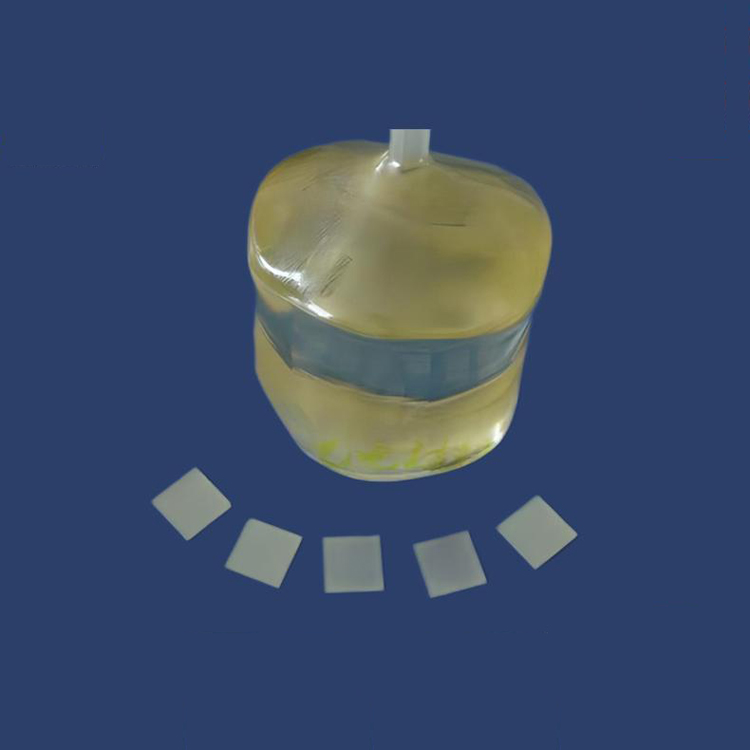

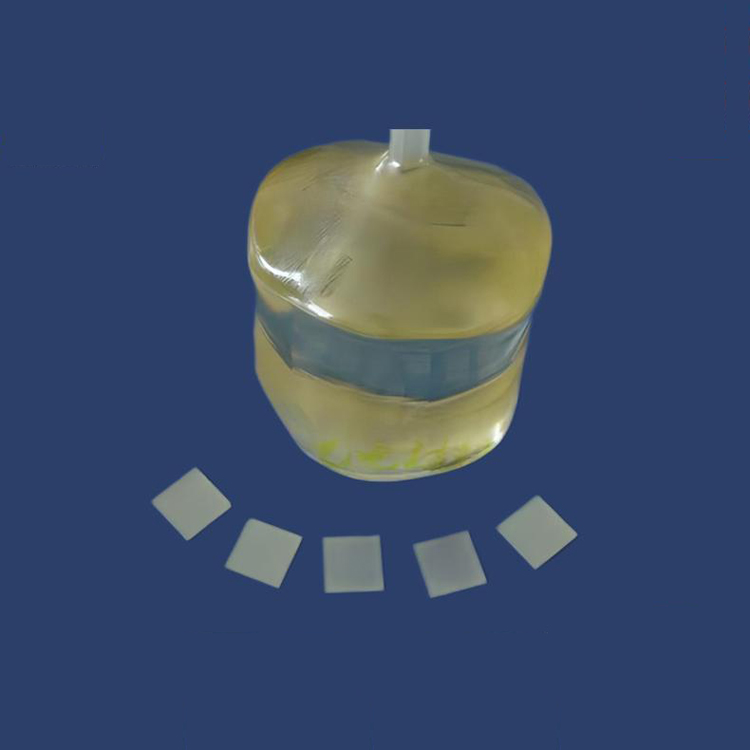

- High purity (≥99.9%).

- Excellent electro-optical and piezoelectric properties.

- Stable chemical and thermal performance.

- Uniform size for consistent evaporation.

- Customizable pellet sizes and shapes.

-

- High Purity: Ensures minimal impurities for superior thin-film quality.

- Exceptional Piezoelectric Properties: Ideal for high-performance acoustic and vibrational devices.

- Stable Electro-Optic Behavior: Suitable for high-precision optical applications.

- Customizable Specifications: Tailored to meet unique system requirements.

- Durable and Reliable: Manufactured for consistent sputtering performance.

-

- Excellent Lattice Matching: Ideal match for many perovskite oxides such as YBCO, BST, and PZT

- High Thermal Stability: Maintains structural integrity under high temperatures

- Low Dielectric Loss: Suitable for microwave and dielectric applications

- High Crystallinity: Enables defect-free epitaxial film growth

- Good Mechanical Strength: Durable for various thin-film deposition processes

- Smooth Surface Finish: Atomic-level flatness for epitaxial growth

- High Chemical Stability: Resists degradation during processing

- Wide Application Range: Compatible with superconducting, ferroelectric, and oxide-based systems

-

- High Mechanical Strength: The combination of molybdenum and tantalum results in an alloy with excellent tensile strength, making it ideal for demanding structural applications.

- Thermal Stability: MoTa alloys maintain their mechanical properties at elevated temperatures, making them suitable for high-temperature applications, such as coatings for turbine components.

- Oxidation and Corrosion Resistance: The alloy exhibits outstanding resistance to oxidation and corrosion, ensuring long-term performance in harsh environments.

- Customizable Composition: The molybdenum-to-tantalum ratio can be tailored to optimize the properties of the alloy for specific applications, enhancing strength, thermal stability, or corrosion resistance.

-

- High Structural Perfection: Ideal lattice matching for growing oxide thin films such as superconductors and ferroelectric films.

- Excellent Dielectric Properties: High dielectric constant makes it suitable for tunable capacitors and microwave applications.

- Low Optical Absorption: Transparent in the visible to near-infrared spectrum, useful for optoelectronic devices.

- High Mechanical and Chemical Stability: Ensures robustness in diverse environments.

- Ferroelectric and Quantum Paraelectric Behavior: Suitable for research in quantum phase transitions and low-temperature physics.

- Epitaxial Growth Substrate: Preferred for epitaxy of functional oxide materials such as high-temperature superconductors, ferroelectric, and multiferroic materials.

-

- Exceptional Corrosion Resistance: Tantalum is highly resistant to chemical attack, particularly in acidic environments, making it ideal for use in corrosive conditions.

- High Melting Point: With a melting point of 3017°C, tantalum foil can withstand extreme temperatures without losing structural integrity.

- Good Conductivity: Tantalum exhibits excellent electrical and thermal conductivity, making it suitable for high-performance electronics and heat dissipation.

- Biocompatibility: Tantalum is non-toxic and biocompatible, allowing its use in medical implants and devices.

- Ductility and Malleability: Tantalum foil is highly ductile and can be easily formed into intricate shapes without cracking, even at room temperature.

- High Purity: Our tantalum foils are available in ultra-high purity grades to meet stringent industrial and scientific requirements.

-

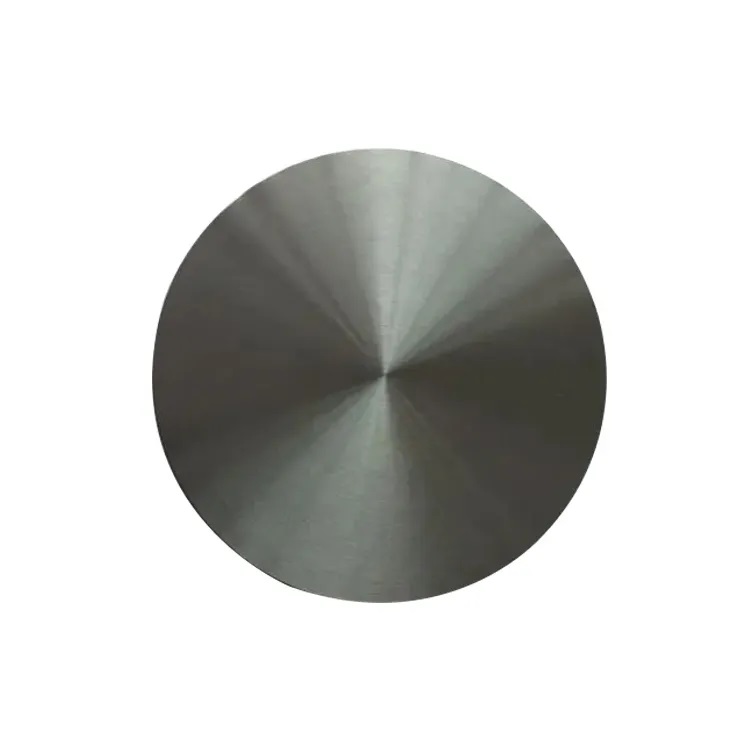

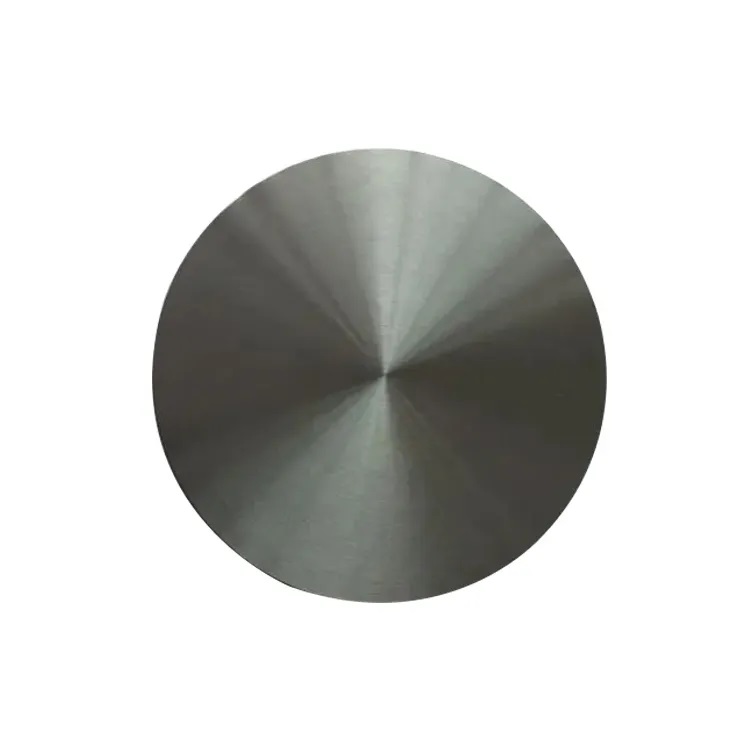

- High Corrosion Resistance: Tantalum provides superior protection against corrosion, especially in acidic and high-temperature environments.

- High Melting Point: Tantalum has a melting point of 3017°C, making it suitable for high-temperature applications.

- Excellent Adhesion: Tantalum adheres well to a variety of substrates, ensuring reliable and durable coatings.

- Biocompatibility: Tantalum is biocompatible and non-toxic, making it ideal for use in medical and dental applications.

- High Purity: Available in high-purity forms (≥ 99.95%) to ensure clean deposition with minimal impurities.