Aluminum (Al) Single Crystal Substrates

- Excellent Surface Flatness: Atomically smooth surfaces after mechanical and chemical polishing

- Superior Purity: Available with purity grades ≥ 99.999% (5N) for high-precision applications

- Outstanding Thermal Conductivity: ~235 W/m·K at 300K

- High Ductility and Malleability: Ideal for deformation and recrystallization studies

- Stable Oxide Layer: Natural formation of a thin Al₂O₃ protective layer

- Corrosion Resistance: Suitable for atmospheric and mild chemical environments

- Customizable Size and Thickness: From small squares to large diameter disks

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Aluminum (Al) single crystals are high-purity metallic substrates featuring an ordered atomic structure throughout the entire specimen. With a face-centered cubic (FCC) crystal structure and excellent ductility, thermal conductivity, and corrosion resistance, Aluminum single crystals are widely utilized in surface science research, epitaxial growth studies, and advanced material development. Their well-defined crystallographic orientation provides a stable platform for fundamental studies of surface reactions, catalytic behavior, and thin-film deposition.

Crystal Structure and Orientation:

- Crystal System: Face-Centered Cubic (FCC)

- Space Group: Fm-3m (No. 225)

- Lattice Constant: a = 4.0495 Å

- Density: 2.70 g/cm³

- Surface Orientations Available:

- (100)

- (110)

- (111)

- Custom orientations (e.g., (210), (311), etc.) upon request

Precise orientation control (within ±0.5° or better) ensures consistent performance in research and epitaxial applications.

Key Properties and Advantages:

- Excellent Surface Flatness: Atomically smooth surfaces after mechanical and chemical polishing

- Superior Purity: Available with purity grades ≥ 99.999% (5N) for high-precision applications

- Outstanding Thermal Conductivity: ~235 W/m·K at 300K

- High Ductility and Malleability: Ideal for deformation and recrystallization studies

- Stable Oxide Layer: Natural formation of a thin Al₂O₃ protective layer

- Corrosion Resistance: Suitable for atmospheric and mild chemical environments

- Customizable Size and Thickness: From small squares to large diameter disks

Typical Applications:

- Surface science and atomic-scale surface studies

- Epitaxial growth substrate for metals and thin films

- Catalysis research, including oxidation and adsorption studies

- Material deformation and dislocation dynamics research

- Calibration standards for electron microscopy and X-ray diffraction

- Nano-fabrication and MEMS applications

- Sensor and microelectronic device research

Specifications:

| Purity | ≥99.999% (5N), optional higher grades |

| Orientation Accuracy | ±0.5° (higher precision available) |

| Thickness Tolerance | ±0.05 mm |

| Surface Finish | Polished (Ra < 5 Å) or As-cut |

| Available Sizes | 5mm × 5mm, 10mm × 10mm, Ø10mm-Ø50mm, Custom sizes |

| Surface Orientation | (100), (110), (111), Custom |

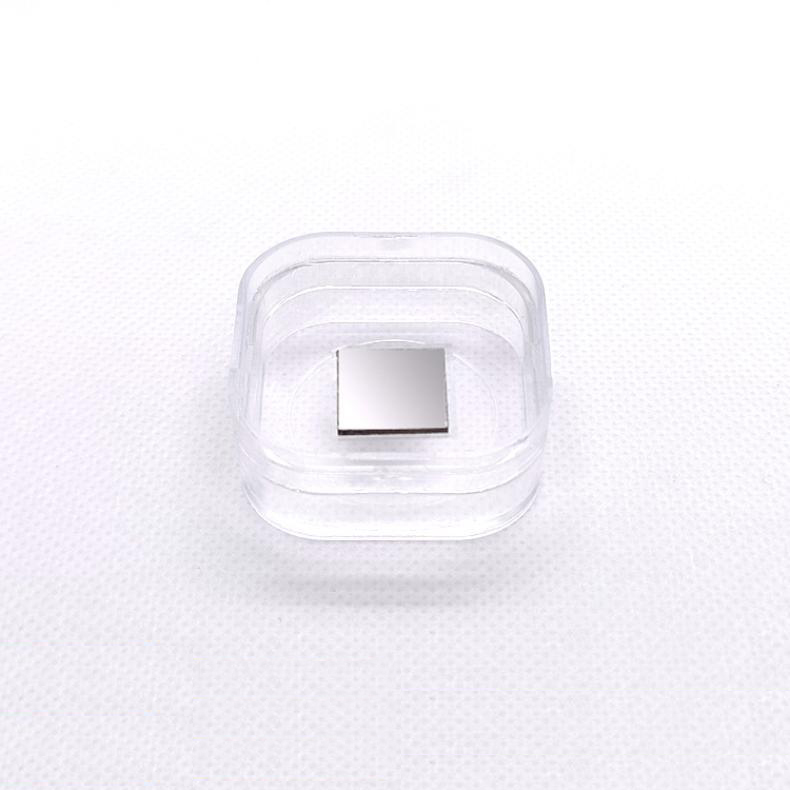

| Packaging | Class 100 cleanroom vacuum packaging |

Optional services include surface cleaning, chemical etching, annealing treatments, and oxide layer control.

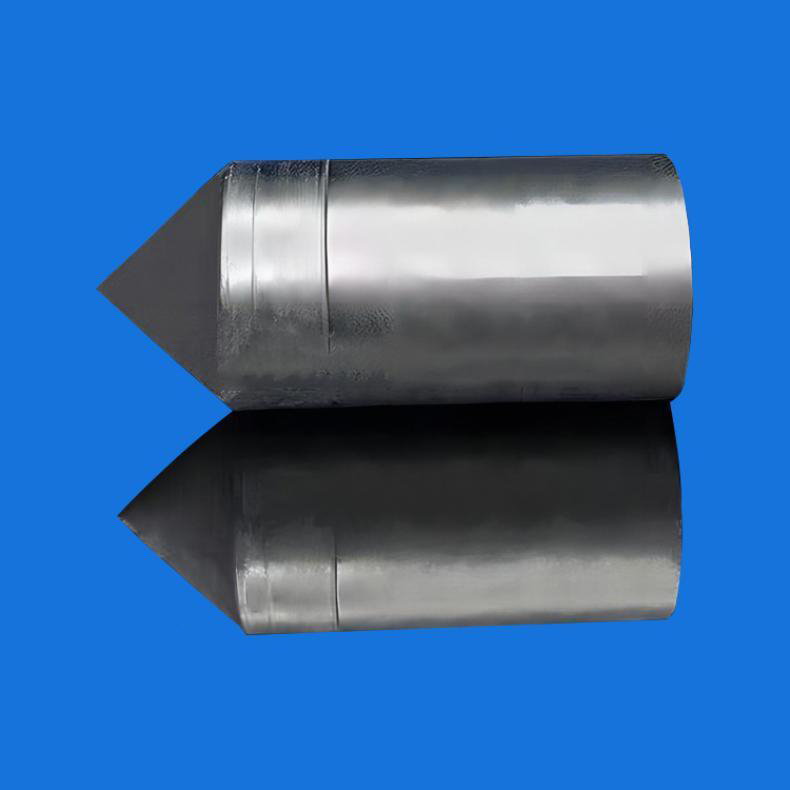

Available Sizes and Customization:

We offer a wide variety of standard dimensions and also support customized dimensions based on customer requirements, including:

- Rectangular pieces

- Circular wafers (up to 50mm diameter)

- Ultra-thin single crystal foils

Miscut angle, special surface treatments, and custom thicknesses are also available to optimize your research outcomes.

Quality Assurance:

Each Aluminum single crystal undergoes rigorous quality control including:

- X-ray Diffraction (XRD) for orientation and crystal quality

- Electron Backscatter Diffraction (EBSD) for surface analysis (optional)

- Surface Roughness Testing (AFM optional)

- Visual and Surface Defect Inspection

- Purity Certification and Inspection Report provided with shipment

All products are processed and packaged in ISO Class 100 or better cleanroom conditions to minimize contamination and oxidation.

Why Choose Our Aluminum Single Crystals?

- Extensive customization for orientation, size, and surface finish

- High-purity materials ensuring minimal impurities and defects

- Competitive pricing with fast lead times

- Comprehensive pre-sale and post-sale technical support

- Proven quality with customers in academic, industrial, and governmental sectors

Ordering & Contact Information:

We offer flexible MOQ (Minimum Order Quantity) and competitive pricing. Our substrates are packaged in Class 100 cleanroom environments and shipped worldwide. For custom orders or technical inquiries, please contact us for a detailed consultation!