CTH:YAG Single Crystal Substrates

- Efficient Eye-Safe Laser Emission: Strong laser output around 2.1 µm, ideal for safe medical and military applications.

- Self-Q-Switching Capability: Enabling compact laser designs without external modulators.

- High Optical Homogeneity: Ensures stable laser performance with minimal beam distortion.

- High Thermal Conductivity: Supports high-power laser operation with effective heat management.

- Long Fluorescence Lifetime: Enhances energy storage for pulsed laser systems.

- Excellent Mechanical and Chemical Stability: Resistant to environmental degradation.

- Direct Diode Pumping Compatibility: Allows for highly efficient, compact laser systems.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

CTH:YAG (Chromium, Thulium, and Holmium co-doped Yttrium Aluminum Garnet) single crystal substrates are highly regarded for their outstanding laser performance in the eye-safe near-infrared (NIR) region, particularly around 2.1 µm.

These substrates are extensively used for solid-state laser applications, medical laser systems, range-finding, lidar, and scientific research.

We offer high-quality CTH:YAG crystals with excellent optical homogeneity, precise orientation, and superior laser properties to meet demanding device fabrication needs.

Crystal Structure and Orientation:

- Chemical Formula: (Cr³⁺, Tm³⁺, Ho³⁺):Y₃Al₅O₁₂

- Crystal Structure: Cubic, garnet structure

- Space Group: Ia3d

- Lattice Constant: a = 12.01 Å

- Density: ~4.56 g/cm³

- Melting Point: ~1970°C

- Thermal Expansion Coefficient: 7.8 × 10⁻⁶/K

- Available Orientations:

- (111) (standard for laser applications)

- (100) and (110) orientations available on request

Key Properties and Advantages:

- Efficient Eye-Safe Laser Emission: Strong laser output around 2.1 µm, ideal for safe medical and military applications.

- Self-Q-Switching Capability: Enabling compact laser designs without external modulators.

- High Optical Homogeneity: Ensures stable laser performance with minimal beam distortion.

- High Thermal Conductivity: Supports high-power laser operation with effective heat management.

- Long Fluorescence Lifetime: Enhances energy storage for pulsed laser systems.

- Excellent Mechanical and Chemical Stability: Resistant to environmental degradation.

- Direct Diode Pumping Compatibility: Allows for highly efficient, compact laser systems.

Typical Applications:

- Eye-safe medical laser systems (e.g., ophthalmology, dermatology)

- Lidar and range-finding systems

- Military and aerospace laser communication

- Remote sensing instruments

- Solid-state mid-infrared laser sources

- Spectroscopy and scientific research lasers

- Laser marking and material processing

Specifications:

| Doping Concentrations | Cr³⁺: ~0.5 at%, Tm³⁺: ~5 at%, Ho³⁺: ~0.36 at% (typical) |

| Diameter | 10 mm – 50 mm (customizable) |

| Thickness | 0.5 mm – 5.0 mm |

| Orientation | <100>, <111>, <110> |

| Surface Finish | Single-side polished (SSP) or double-side polished (DSP) |

| Surface Quality | 10-5 or 20-10 Scratch-Dig (per MIL-PRF-13830B) |

| Parallelism | < 10 arc seconds |

| Surface Flatness | λ/10 @ 632.8 nm |

| Extinction Ratio | > 25 dB (for optical axis accuracy) |

| Crystal Growth Method | Czochralski method |

Available Sizes and Customization:

- Sizes: 10 mm × 10 mm, 20 mm × 20 mm, 25 mm diameter, custom

- Thickness Options: 0.5 mm, 1 mm, 2 mm, up to 5 mm, customizable

- Surface Polishing:

- DSP (Double-Side Polished) for epitaxial growth and laser cavities

- SSP (Single-Side Polished) for mounting or bonding

- Orientation Tolerance: ±0.5°

- Edge Options: Laser-cut, bevelled or chamfered edges for safe handling

- Defect Control: Low dislocation density and minimal inclusions

Quality Assurance:

Our CTH:YAG substrates are produced and processed under strict quality control standards:

- High-Resolution X-Ray Diffraction (HRXRD) to confirm crystal perfection

- Polarized light microscopy to inspect internal defects

- Surface quality verified by optical interferometry and scratch-dig inspection

- Chemical and mechanical stability tested under harsh conditions

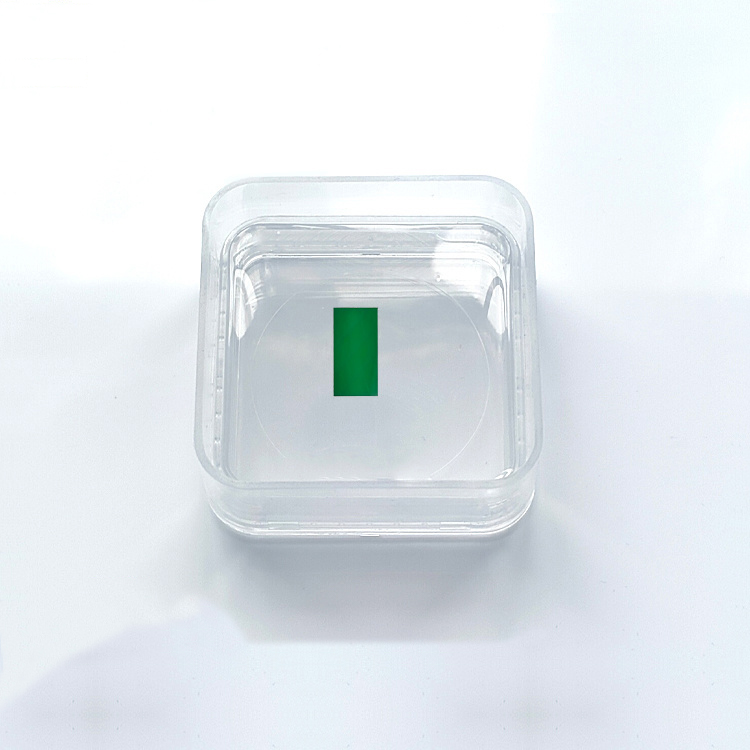

- Cleanroom packaging (Class 1000) ensures contamination-free delivery

Why Choose Our CTH:YAG Single Crystal Substrates?

- High optical uniformity and superior laser performance

- Accurate doping levels for optimal eye-safe 2.1 µm laser emission

- High mechanical strength and chemical durability

- Custom sizes, orientations, and finishes available

- Strict quality assurance and full technical support

- Fast delivery and worldwide shipping services

Ordering & Contact Information:

Tinsan Materials offers flexible MOQ (Minimum Order Quantity) and competitive pricing. Our substrates are packaged in Class 100 cleanroom environments and shipped worldwide. For custom orders or technical inquiries, please contact us for a detailed consultation!