Er:YAG Crystal (Erbium-doped Yttrium Aluminum Garnet)

- Strong and efficient emission at 2940 nm, ideal for water-rich tissue targeting

- Direct pumping at 980 nm or 1532 nm allows use of commercially available diode lasers

- High slope efficiency and low quantum defect, minimizing thermal load

- High thermal conductivity (~11 W/m·K) for superior heat dissipation

- Stable performance under high average and peak power operations

- High optical homogeneity and low absorption losses

- Durable mechanical properties, chemically stable in demanding environments

- Broad transparency range: 0.5 μm to 5.5 μm

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

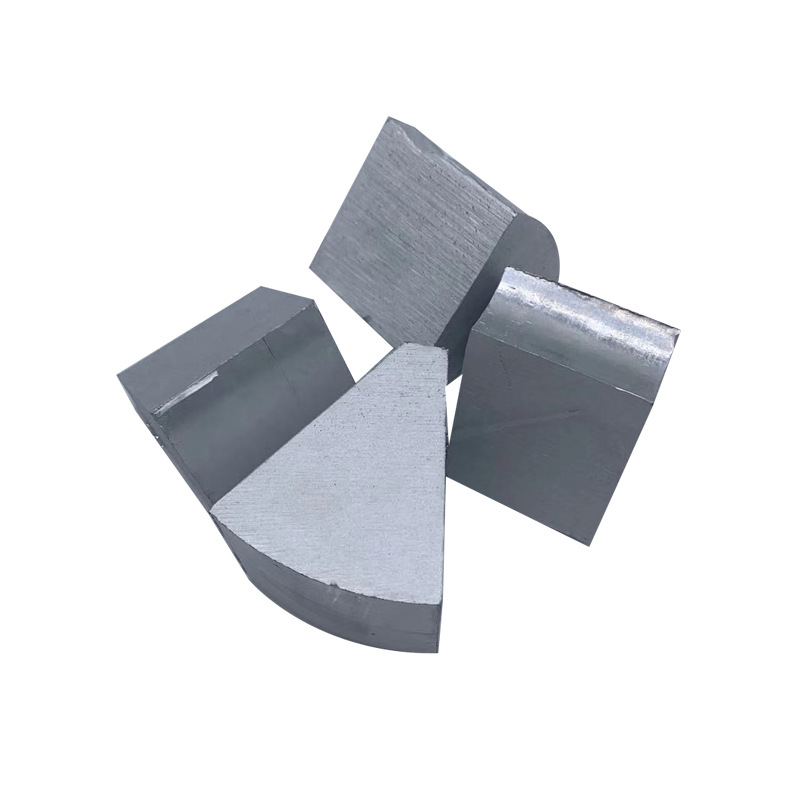

Er:YAG (Erbium-doped Yttrium Aluminum Garnet) is a laser crystal belonging to the garnet family, known for its high-efficiency emission at 2.94 μm in the mid-infrared region. This wavelength corresponds precisely to the peak absorption of water molecules, making Er:YAG an ideal material for medical and dermatological applications where controlled ablation and minimal thermal damage are critical. Beyond healthcare, Er:YAG is gaining prominence in precision industrial processing and mid-infrared spectroscopy due to its excellent thermal and optical properties.

Er:YAG is produced using the Czochralski method to ensure high crystalline quality, minimal scattering losses, and precise control of dopant concentrations. It supports both continuous wave (CW) and Q-switched or pulsed laser operation, enabling versatile usage across diverse platforms.

Key Features

- Strong and efficient emission at 2940 nm, ideal for water-rich tissue targeting

- Direct pumping at 980 nm or 1532 nm allows use of commercially available diode lasers

- High slope efficiency and low quantum defect, minimizing thermal load

- High thermal conductivity (~11 W/m·K) for superior heat dissipation

- Stable performance under high average and peak power operations

- High optical homogeneity and low absorption losses

- Durable mechanical properties, chemically stable in demanding environments

- Broad transparency range: 0.5 μm to 5.5 μm

Applications

- Medical and Dental Lasers: Er:YAG is widely used in minimally invasive surgeries, dental hard tissue procedures, and aesthetic skin resurfacing treatments. The 2940 nm output offers efficient tissue vaporization with reduced collateral damage.

- Aesthetic and Cosmetic Dermatology: Popular in fractional laser systems for wrinkle reduction, scar treatment, and skin rejuvenation, thanks to its shallow penetration depth and precise ablation.

- Industrial Processing: Enables micro-machining, polymer and ceramic processing, and other precision material removal applications where infrared absorption is desired.

- Scientific Research: Used in building tunable mid-infrared laser systems, molecular spectroscopy, and nonlinear optics studies.

Technical Specifications

| Chemical Formula | Er:Y₃Al₅O₁₂ |

| Crystal Structure | Cubic, space group Ia3d (Garnet type) |

| Emission Wavelength | 2940 nm |

| Pump Wavelengths | 980 nm, 1532 nm |

| Refractive Index | ~1.83 @ 2940 nm |

| Fluorescence Lifetime | ~8 ms (@ room temperature) |

| Thermal Conductivity | ~11 W/m·K |

| Density | 4.56 g/cm³ |

| Mohs Hardness | 8.25 |

| Transparency Range | 0.5 μm – 5.5 μm |

| Typical Sizes | φ3-20 mm; Length: 30-100 mm (customizable) |

| Orientation | <111> or <100>, depending on application |

| Surface Finish | Laser-grade polished (10/5 S/D typical) |

Customization Options

Tinsan Materials offers Er:YAG crystals tailored to meet diverse laser system requirements:

- Doping Concentration: Available from 0.2 to 1.5 at.% Er³⁺, with standard options at 0.5%, 0.75%, and 1.0%

- Dimensions: Diameter from 3 mm to 20 mm; length up to 100 mm or more upon request

- End Surface: Plano-plano, plano-wedge, or angled facets depending on resonator design

- Surface Quality: Laser-grade polishing with optional AR coating for 980 nm or 2940 nm

- Crystal Orientation: <111> or <100> cut to suit pumping configuration and thermal management

- Coatings: Custom dielectric coatings (AR, HR, dichroic) per user specifications

Technical Support

Tinsan Materials is committed to providing comprehensive technical support, including:

- Crystal selection guidance based on application

- Laser cavity design assistance

- Custom coating and optical interface consulting

- Thermal and mechanical integration advice

- Ongoing post-sale technical support and troubleshooting

Our engineers are available to assist you in optimizing your Er:YAG-based systems for maximum output and stability.

Ordering & Contact Information

We offer flexible MOQ (Minimum Order Quantity), competitive pricing and global shipping. For custom orders or technical inquiries, please contact us for a detailed consultation!