LaAlO3 Single Crystal Substrates

- Excellent Crystal Quality: Low dislocation density, high structural perfection.

- Ideal Lattice Match: Close lattice parameters with materials like YBCO, LSMO, PZT, and other perovskite oxides.

- High Thermal Stability: Suitable for high-temperature thin film deposition processes.

- High Dielectric Constant: Beneficial for microwave devices and tunable capacitors.

- Low Dielectric Loss: Ensures superior performance at high frequencies.

- Chemical Stability: Strong resistance to acids and bases.

- Atomically Smooth Surface: Achieved through advanced polishing and chemical etching processes.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Lanthanum Aluminate (LaAlO₃, or LAO) is a high-quality perovskite oxide single crystal substrate that offers excellent lattice matching with many complex oxide thin films, especially high-temperature superconductors, ferroelectric materials, and multiferroics. LAO substrates are highly valued for their exceptional dielectric properties, low microwave loss, and chemical stability, making them ideal for use in thin film deposition, epitaxial growth, microelectronics, and photonic devices.

Key Features:

- Excellent Crystal Quality: Low dislocation density, high structural perfection.

- Ideal Lattice Match: Close lattice parameters with materials like YBCO, LSMO, PZT, and other perovskite oxides.

- High Thermal Stability: Suitable for high-temperature thin film deposition processes.

- High Dielectric Constant: Beneficial for microwave devices and tunable capacitors.

- Low Dielectric Loss: Ensures superior performance at high frequencies.

- Chemical Stability: Strong resistance to acids and bases.

- Atomically Smooth Surface: Achieved through advanced polishing and chemical etching processes.

Technical Specifications:

| Crystal Structure | Pseudo-cubic (Rhombohedral at room temperature) |

| Lattice Constant | a = 3.789 Å (pseudo-cubic) |

| Density | 6.52 g/cm³ |

| Melting Point | ~2080°C |

| Dielectric Constant (at 1 MHz) | ~24 |

| Thermal Expansion Coefficient | ~10 × 10⁻⁶ /K |

| Hardness (Mohs) | ~6 |

| Orientation Available | (100), (110), (111) |

| Size Range | 5 × 5 mm² up to 50 × 50 mm²; customized sizes available |

| Thickness Range | 0.25 mm, 0.5 mm, 1.0 mm, or customized |

| Surface Finish | Single side polished (SSP) or double side polished (DSP) |

| Surface Roughness | Ra < 5 Å (after polishing) |

Manufacturing Process:

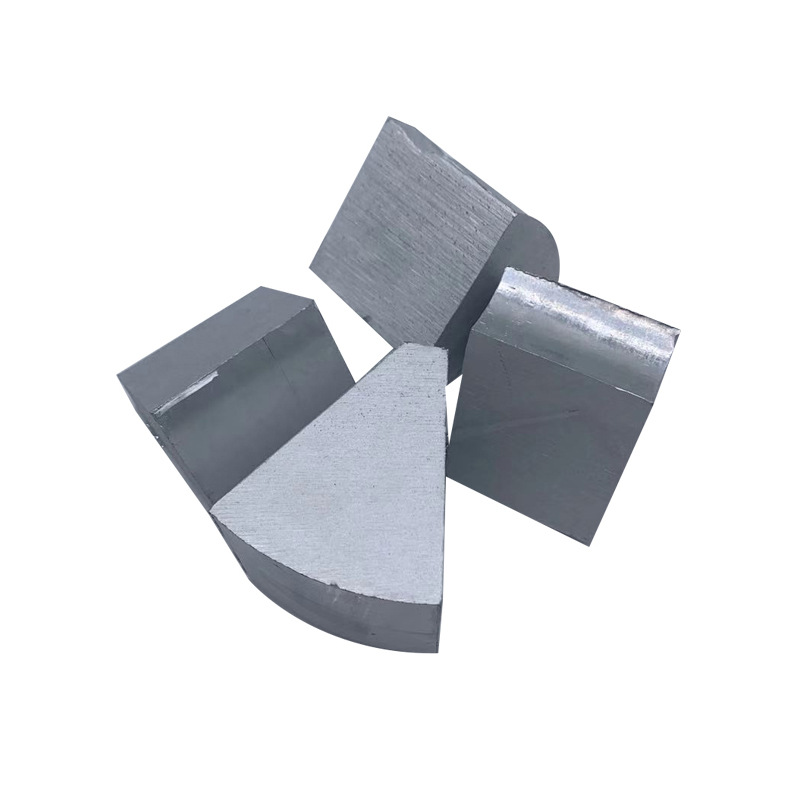

- Crystal Growth: Grown using the Czochralski method with strict control over stoichiometry and defect minimization.

- Orientation Cutting: High-precision Laue back-reflection or XRD orientation.

- Surface Processing: Double side polishing or single side polishing to achieve atomic-level smoothness.

- Annealing: High-temperature annealing to improve crystallinity and remove internal stress.

- Quality Inspection: X-ray diffraction (XRD), atomic force microscopy (AFM), and visual inspection to ensure perfect quality.

Applications:

- Growth of high-temperature superconducting films such as YBa₂Cu₃O₇₋δ (YBCO)

- Deposition of ferroelectric thin films like PZT (Pb(Zr,Ti)O₃)

- Fabrication of multiferroic thin films (e.g., BiFeO₃)

- Microwave devices and dielectric resonators

- Tunable capacitors and high-frequency components

- Oxide electronics and epitaxial oxide heterostructures

- Optical and photonic devices

Available Sizes and Customization Options:

- Size Range: 5 × 5 mm² up to 50 × 50 mm²; customized sizes available.

- Thickness Range: 0.25 mm, 0.5 mm, 1.0 mm, or customized.

- Orientation: (100), (110), (111), custom orientations (miscut angles, off-axis) available.

- Surface Finish: Single side polished (SSP) or double side polished (DSP)

- Special treatments such as acid etching, annealing, or chemical polishing on request.

Quality Assurance:

- XRD Analysis: Full-width half-maximum (FWHM) measurements to ensure minimal mosaic spread.

- AFM Surface Characterization: Verifying atomic-level smoothness and uniformity.

- Laue Back Reflection: Precise orientation verification within ±0.5°.

- Visual Inspection: Ensures no scratches, pits, or cracks.

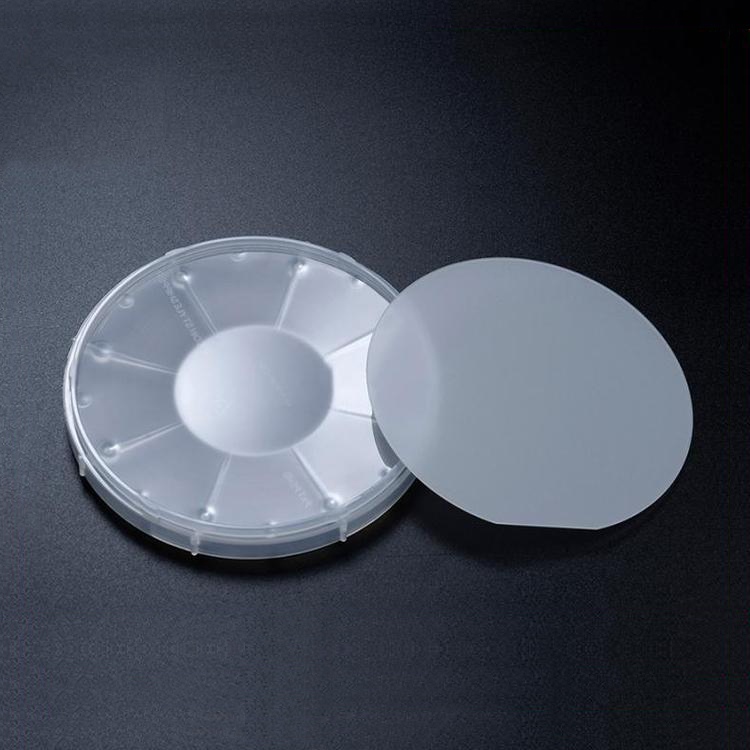

- Packaging: Class 100 cleanroom environment, double-layer vacuum-sealed packaging to ensure pristine condition during shipment.

Why Choose Our LaAlO₃ Substrates?

- Over 10 years of experience supplying high-quality oxide substrates.

- High stock availability for standard sizes and orientations.

- Customization service for size, thickness, miscut angle, and surface finish.

- Competitive pricing and fast lead times.

- Dedicated technical support for material selection and application guidance.

Frequently Asked Questions (FAQ):

Q1: What thin films are best suited for growth on LaAlO₃ substrates?

A1: LaAlO₃ substrates are ideal for growing high-temperature superconductors like YBa₂Cu₃O₇₋δ (YBCO), ferroelectric thin films like Pb(Zr,Ti)O₃ (PZT), multiferroic materials such as BiFeO₃, and colossal magnetoresistive oxides like La₁₋ₓSrₓMnO₃ (LSMO).

Q2: What polishing options are available for LaAlO₃ wafers?

A2: We offer both single side polished (SSP) and double side polished (DSP) LaAlO₃ substrates. The surface roughness after polishing can reach Ra < 5 Å, suitable for high-quality epitaxial film deposition.

Q3: Can you supply LaAlO₃ substrates with a specific miscut angle?

A3: Yes. Custom miscut angles (e.g., 0.5°, 1°, 2°, etc.) are available upon request. Precise orientation control helps promote step-flow growth modes in epitaxial films.

Q4: How are the substrates packaged to avoid contamination?

A4: All LaAlO₃ substrates are cleaned in Class 100 cleanroom environments, individually vacuum-sealed in clean pouches, and packed in shockproof boxes to ensure safe transportation.

Ordering & Contact Information:

We offer flexible MOQ (Minimum Order Quantity) and competitive pricing. Our substrates are packaged in Class 100 cleanroom environments and shipped worldwide. For custom orders or technical inquiries, please contact us for a detailed consultation!