Lithium Fluoride (LiF) Single Crystal Substrates

- Wide Transmission Range: Excellent optical transmission from 120 nm (VUV) to 6 μm (IR).

- Low Refractive Index: ~1.39 at 400 nm, advantageous for minimal Fresnel losses.

- Radiation Resistance: High durability against X-rays and high-energy particle irradiation.

- High Optical Homogeneity: Suitable for precision optics and laser systems.

- Good Mechanical Properties: Higher hardness compared to other VUV transparent materials like CaF₂.

- Low Birefringence: Enabling better performance in polarization-sensitive applications.

- Chemical Stability: Moderate chemical inertness; surface can be protected with appropriate coatings if needed.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

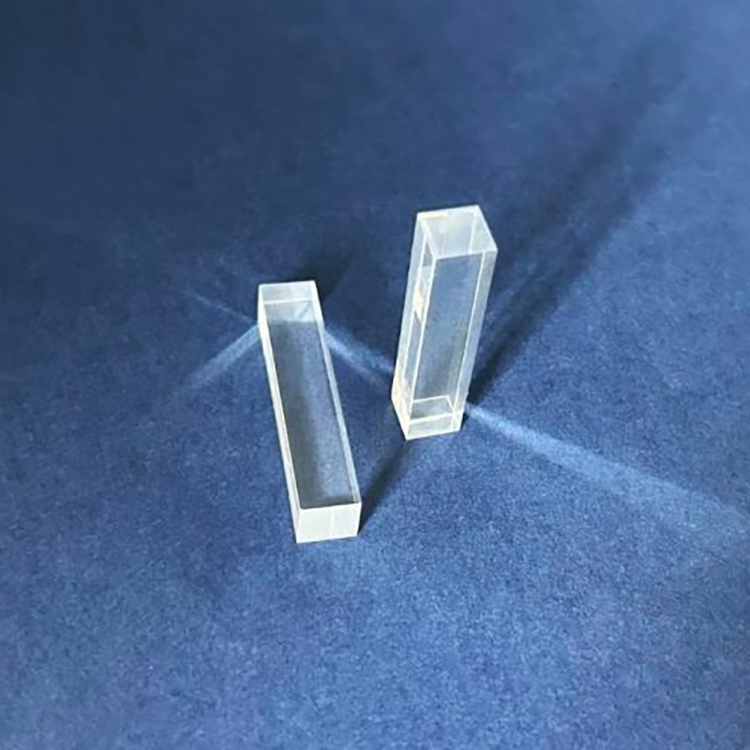

Lithium Fluoride (LiF) single crystal substrates are highly valued for their exceptional transparency across a wide spectral range, from the vacuum ultraviolet (VUV) to the infrared (IR) region. LiF crystals exhibit extremely low refractive indices, high radiation resistance, and good mechanical strength. These properties make LiF substrates indispensable in applications such as VUV optics, deep UV lithography, X-ray optics, high-energy lasers, and scintillation detectors.

Key Features and Properties:

- Wide Transmission Range: Excellent optical transmission from 120 nm (VUV) to 6 μm (IR).

- Low Refractive Index: ~1.39 at 400 nm, advantageous for minimal Fresnel losses.

- Radiation Resistance: High durability against X-rays and high-energy particle irradiation.

- High Optical Homogeneity: Suitable for precision optics and laser systems.

- Good Mechanical Properties: Higher hardness compared to other VUV transparent materials like CaF₂.

- Low Birefringence: Enabling better performance in polarization-sensitive applications.

- Chemical Stability: Moderate chemical inertness; surface can be protected with appropriate coatings if needed.

Typical Applications:

- VUV and UV optical components

- X-ray and gamma-ray optics and detectors

- Windows for high-energy laser systems

- Deep ultraviolet (DUV) lithography

- Scintillator components for radiation detection

- Spectroscopic instrumentation

- Optical prisms and lenses for specialized UV systems

Specifications:

| Chemical Formula | LiF |

| Crystal Structure | Cubic (NaCl type) |

| Space Group | Fm3m |

| Lattice Constant | a = 4.026 Å |

| Density | 2.635 g/cm³ |

| Melting Point | 845°C |

| Mohs Hardness | ~4 |

| Thermal Expansion Coefficient | ~37 × 10⁻⁶/K |

| Transmission Range | 120 nm – 6.0 μm |

| Refractive Index (at 400 nm) | ~1.39 |

| Surface Quality | 20/10 (Scratch/Dig) |

| Surface Flatness | <λ/8 @ 632.8 nm |

| Standard Orientation | (100), (110), (111) |

| Available Sizes | 10×10 mm², 20×20 mm², 50×50 mm², etc. |

| Typical Thickness | 0.5 mm to 5.0 mm |

| Surface Finish | SSP or DSP |

Material Properties and Crystal Structure:

- Chemical Formula: LiF

- Crystal Structure: Cubic, NaCl-type (FCC)

- Space Group: Fm3m

- Lattice Constant: a = 4.026 Å

- Density: 2.635 g/cm³

- Mohs Hardness: ~4

- Melting Point: 845°C

- Thermal Expansion Coefficient: ~37 × 10⁻⁶/K

- Optical Transmission Range: 120 nm – 6.0 μm

- Refractive Index: ~1.39 at 400 nm

- Radiation Damage Threshold: Very high compared to other fluoride crystals

Standard Product Sizes and Availability:

- Standard wafer sizes: 10×10 mm², 20×20 mm², 25×25 mm², 50×50 mm²

- Thickness range: 0.5 mm to 5.0 mm (customizable)

- Surface finishing: Single side polished (SSP) or double side polished (DSP)

- Orientation: (100), (110), (111) available

- Surface Quality: 20/10 or better (Scratch/Dig, MIL-PRF-13830B standard)

- Surface Flatness: <λ/8 at 632.8 nm

- Edge options: Standard edge, beveled edge

- Custom shapes and specifications available upon request

Customization Options:

- Specific orientation and tolerance control (e.g., ±0.5°)

- Surface roughness optimization for ultra-high precision optics

- Anti-reflection coatings for UV, VUV, or IR ranges

- Custom sizes, thicknesses, and edge treatments

- Specialized doping options if needed for scintillation or detector use

- Vacuum or cleanroom-grade packaging

Packaging and Delivery:

- Cleanroom-grade packaging in Class 100 environment

- Vacuum-sealed to prevent moisture absorption

- Packed with moisture-absorbing desiccants

- Full material and quality certification (optical inspection, XRD orientation report, etc.)

Why Choose Our Lithium Fluoride (LiF) Single Crystal Substrates?

- High-purity lithium fluoride crystals grown using the Czochralski method

- Precision cutting and polishing to ensure minimal optical loss

- Ability to handle ultra-thin wafers and large-size crystals

- Strong quality control for defect-free, highly transparent substrates

- Flexible customization and rapid response to specific application needs

- Technical consulting and dedicated after-sales support

Ordering & Contact Information:

We offer flexible MOQ (Minimum Order Quantity) and competitive pricing. Our substrates are packaged in Class 100 cleanroom environments and shipped worldwide. For custom orders or technical inquiries, please contact us for a detailed consultation!