Lithium Triborate (LBO) Crystals

- Wide Transparency Range: 160 nm to 2600 nm

- Broad Phase-Matching Capability: Suitable for SHG, THG, OPO, SFG, DFG across UV to IR

- High Damage Threshold: >2 GW/cm² for 1064 nm, 10 ns pulse

- Low Walk-Off Angle: Ideal for high-beam-quality laser systems

- High Nonlinear Coefficients: Enables efficient frequency conversion

- Excellent Optical Homogeneity: Δn < 10⁻⁶/cm

- Good Mechanical Hardness: Mohs hardness ~6

- Stable Physical and Chemical Properties: Resistant to humidity and environmental degradation

- Nonhygroscopic: No special humidity control required

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

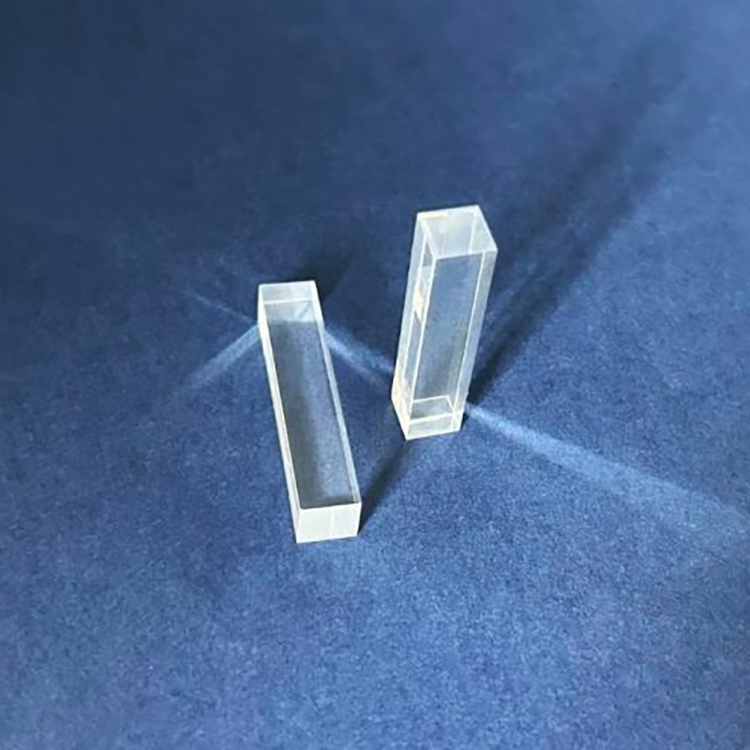

Lithium Triborate (LBO) crystals are high-performance nonlinear optical (NLO) materials widely used in frequency conversion applications such as second harmonic generation (SHG), third harmonic generation (THG), optical parametric oscillation (OPO), and sum-frequency generation (SFG). LBO crystals are celebrated for their broad transparency range, high damage threshold, excellent optical homogeneity, wide phase-matching capability, and good mechanical and chemical stability. These features make LBO crystals a superior choice for high-power, high-stability laser systems in both industrial and scientific fields.

Key Features and Properties:

- Wide Transparency Range: 160 nm to 2600 nm

- Broad Phase-Matching Capability: Suitable for SHG, THG, OPO, SFG, DFG across UV to IR

- High Damage Threshold: >2 GW/cm² for 1064 nm, 10 ns pulse

- Low Walk-Off Angle: Ideal for high-beam-quality laser systems

- High Nonlinear Coefficients: Enables efficient frequency conversion

- Excellent Optical Homogeneity: Δn < 10⁻⁶/cm

- Good Mechanical Hardness: Mohs hardness ~6

- Stable Physical and Chemical Properties: Resistant to humidity and environmental degradation

- Nonhygroscopic: No special humidity control required

Typical Applications:

- Frequency doubling (SHG) of Nd:YAG, Nd:YVO₄, Nd:YLF lasers

- Tripling (THG) for producing UV wavelengths

- Optical parametric oscillators (OPO) and optical parametric amplifiers (OPA)

- Sum-frequency generation (SFG) and difference-frequency generation (DFG)

- High power, high repetition rate laser systems

- Tunable laser sources covering UV, visible, and near-IR regions

- Ultrafast pulse generation and amplification

Specifications:

| Chemical Formula | LiB₃O₅ |

| Crystal Structure | Orthorhombic |

| Space Group | Pna2₁ |

| Lattice Constants | a = 8.447 Å, b = 7.378 Å, c = 5.139 Å |

| Density | ~2.47 g/cm³ |

| Melting Point | 834°C |

| Hardness (Mohs) | ~6 |

| Transparency Range | 160 nm – 2600 nm |

| Nonlinear Coefficient (d₃₁) | ~0.85 pm/V |

| Damage Threshold | >2 GW/cm² at 1064 nm, 10 ns |

| Refractive Indices | n varies with wavelength |

| Phase-Matching Types | Type I and Type II |

| Surface Quality | 10/5 – 20/10 Scratch/Dig |

| Parallelism | <10 arc seconds |

| Flatness | <λ/8 @ 632.8 nm |

| Available Sizes | 3×3×10 mm³, 4×4×15 mm³, 5×5×20 mm³, custom |

| Coating Options | AR coated or uncoated, UV to IR coatings |

Material Properties and Crystal Structure:

- Chemical Formula: LiB₃O₅

- Crystal Structure: Orthorhombic

- Space Group: Pna2₁

- Lattice Constants: a = 8.447 Å, b = 7.378 Å, c = 5.139 Å

- Density: ~2.47 g/cm³

- Melting Point: 834°C

- Mohs Hardness: ~6

- Transparency Range: 160 nm – 2600 nm

- Refractive Indices: nₓ, nᵧ, n𝓏 varies with wavelength

- Nonlinear Coefficient (d₃₁): ~0.85 pm/V

- Damage Threshold: >2 GW/cm² at 1064 nm, 10 ns pulse

- Phase-Matching Types: Type I and Type II achievable

Standard Product Sizes and Availability:

- Typical dimensions: 3×3×10 mm³, 4×4×15 mm³, 5×5×20 mm³, custom sizes available

- Orientation:

- SHG phase matching at θ = 90°, φ = 0° (Type I at 1064 nm)

- Other customized phase-matching angles available

- Surface Quality: 10/5 to 20/10 Scratch/Dig (MIL-PRF-13830B standard)

- Parallelism: <10 arc seconds

- Flatness: <λ/8 @ 632.8 nm

- Surface Finish: Polished or as-cut

- Coatings: AR coatings for 1064 nm, 532 nm, 355 nm, 266 nm, custom coating services

Customization Options:

- Special phase-matching cuts and custom angles

- Custom sizes for specific laser cavity designs

- High damage threshold AR coatings for UV, VIS, or IR applications

- Special polishing and wedge angles for minimizing back reflections

- Bonded LBO crystals for advanced frequency conversion setups

- Temperature-tuned phase-matching designs

Packaging and Delivery:

- Packaged in cleanroom-grade containers, Class 100 clean environment

- Protective cushioning against mechanical shock and moisture

- Sealed in moisture-proof, anti-static packaging

- Fast delivery: 2–4 weeks for standard sizes, 4–6 weeks for custom crystals

- Documentation included: Optical certification, phase-matching test report, coating specifications (if applicable)

Why Choose Our Lithium Triborate (LBO) Crystals?

- Over 10 years of experience in growing high-quality LBO crystals

- Advanced Czochralski pulling technique for superior crystal uniformity

- Rigorous quality control for optical homogeneity and phase-matching accuracy

- Capability to supply crystals from laboratory needs to mass production

- Custom-engineered solutions tailored to customer laser system requirements

- Comprehensive technical support and after-sales service

Ordering & Contact Information:

We offer flexible MOQ (Minimum Order Quantity), competitive pricing and global shipping. For custom orders or technical inquiries, please contact us for a detailed consultation!