Magnesium Aluminate Spinel (MgAl2O4) Single Crystal Substrates

- Excellent Thermal Stability: Suitable for high-temperature processing (melting point ~2135°C)

- Wide Optical Transmission: From 200 nm (UV) to 5000 nm (Mid-IR)

- Superior Mechanical Strength: High hardness and fracture toughness

- Low Thermal Expansion: 8.5 × 10⁻⁶ /°C at 25°C

- High Chemical Resistance: Stable in both acidic and alkaline environments

- Low Dielectric Loss: Favorable for microwave and RF applications

- Surface Quality: Polished to atomic-level smoothness (Ra < 5 Å)

- High Purity: Low levels of impurities ensuring consistent and repeatable results

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Magnesium Aluminate Spinel (MgAl₂O₄) single crystal substrates are high-quality oxide substrates with excellent mechanical strength, thermal stability, and broad optical transparency from ultraviolet (UV) to mid-infrared (IR) wavelengths. With a cubic crystal structure, MgAl₂O₄ substrates offer low dislocation density and outstanding chemical resistance, making them ideal for a variety of applications including epitaxial growth of III-V nitrides, optical components, and thin-film research. Their robust properties and excellent surface polishability make them a preferred choice for demanding optical and electronic applications.

Crystal Structure and Orientation:

- Crystal System: Cubic

- Space Group: Fd-3m (No. 227)

- Lattice Constant: a = 8.08 Å

- Density: 3.58 g/cm³

- Surface Orientations Available:

- (100)

- (110)

- (111)

Orientation accuracy is typically within ±0.5°, and substrates can be customized with special orientations or miscut angles as required by specific applications.

Key Properties and Advantages:

- Excellent Thermal Stability: Suitable for high-temperature processing (melting point ~2135°C)

- Wide Optical Transmission: From 200 nm (UV) to 5000 nm (Mid-IR)

- Superior Mechanical Strength: High hardness and fracture toughness

- Low Thermal Expansion: 8.5 × 10⁻⁶ /°C at 25°C

- High Chemical Resistance: Stable in both acidic and alkaline environments

- Low Dielectric Loss: Favorable for microwave and RF applications

- Surface Quality: Polished to atomic-level smoothness (Ra < 5 Å)

- High Purity: Low levels of impurities ensuring consistent and repeatable results

Typical Applications:

- Epitaxial growth of GaN, AlN, and other III-V/III-N semiconductors

- Substrate for laser and optoelectronic devices

- Optical windows and lenses for UV to IR applications

- High-temperature furnace components

- Substrates for high-power RF/microwave devices

- Surface acoustic wave (SAW) and bulk acoustic wave (BAW) devices

- Research in crystallography, thin-film physics, and material science

Specifications:

| Purity | ≥99.99% |

| Orientation Accuracy | ±0.5° (higher precision available) |

| Thickness Tolerance | ±0.05 mm |

| Surface Finish | Double-side polished (Ra < 5 Å) or As-cut |

| Available Sizes | 5×5mm, 10×10mm, Ø1″, Ø2″, Ø3″, Custom sizes |

| Surface Orientations | (100), (110), (111), Custom |

| Packaging | Class 100 cleanroom vacuum packaging |

Polishing options include chemical-mechanical polishing (CMP) to achieve atomically flat surfaces for high-precision epitaxial applications.

Available Sizes and Customization:

We offer a wide variety of standard and customized MgAl₂O₄ substrates:

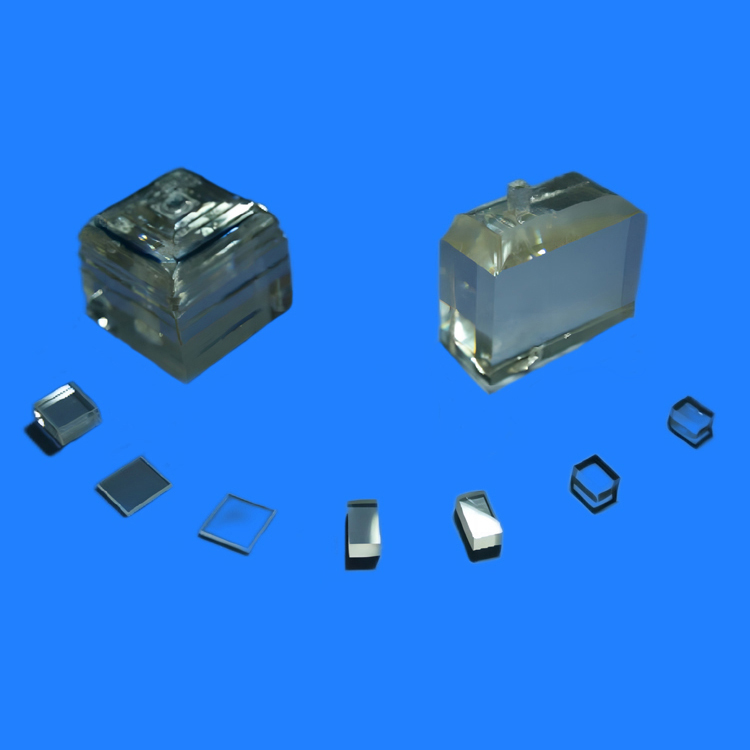

- Square substrates: 5×5mm, 10×10mm, 20×20mm, etc.

- Circular wafers: Ø25.4mm (1″), Ø50.8mm (2″), Ø76.2mm (3″), Ø100mm (4″), etc.

- Thickness: From 0.3mm to 2.0mm standard; other thicknesses on request

- Custom options:

- Specific miscut angles

- Backside roughening

- Edge chamfering

- Laser marking

Custom polishing and crystal orientations are also available to meet special epitaxial growth requirements.

Quality Assurance:

Each MgAl₂O₄ substrate undergoes strict quality control measures:

- High-Resolution X-Ray Diffraction (HRXRD) analysis for orientation and crystal quality

- Surface roughness measured by Atomic Force Microscopy (AFM)

- Optical and visual inspection under cleanroom conditions

- Surface flatness, parallelism, and thickness checked with precision instruments

- Purity certification and full inspection reports provided with each batch

Products are handled, processed, and packaged in ISO Class 100 cleanroom environments to guarantee exceptional cleanliness and minimal contamination.

Why Choose Our Magnesium Aluminate (MgAl₂O₄) Single Crystal Substrates?

- Ultra-high surface quality for demanding optical and epitaxial applications

- Excellent optical transparency from UV to IR regions

- Superior mechanical strength and chemical resistance

- Wide variety of sizes, orientations, and customizations available

- Fast production lead times with consistent quality control

- Full technical support for epitaxial growth, device fabrication, and surface treatments

Ordering & Contact Information:

We offer flexible MOQ (Minimum Order Quantity) and competitive pricing. Our substrates are packaged in Class 100 cleanroom environments and shipped worldwide. For custom orders or technical inquiries, please contact us for a detailed consultation!

KTN Crystal (KTa₀.₅Nb₀.₅O₃) – Orientation, 10 × 10 × 0.5 mm

KTN Crystal (KTa₀.₅Nb₀.₅O₃) – Orientation, 10 × 10 × 0.5 mm