Magnesium (Mg) Single Crystal Substrates

- Lightest Structural Metal: Exceptionally low density for weight-sensitive applications

- Excellent Specific Strength: High strength-to-weight ratio

- Anisotropic Mechanical Properties: Ideal for deformation and slip system studies

- High Ductility at Elevated Temperatures: Improved formability in warm/hot conditions

- Good Machinability: Easier to process compared to other metals

- High Thermal Conductivity: Facilitates efficient heat dissipation

- Superior Homogeneity: Enables reproducible experimental results

- Corrosion Sensitivity: Useful for corrosion research and protective coating studies

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Magnesium (Mg) single crystals are high-purity metallic crystals characterized by a hexagonal close-packed (HCP) structure. As the lightest structural metal, magnesium single crystals exhibit outstanding specific strength, excellent machinability, and unique deformation mechanisms such as twinning and slip, making them ideal for fundamental material science research, deformation studies, and applications requiring lightweight and high-performance materials. The superior homogeneity and defect control of single crystalline magnesium enable precise investigations into its mechanical, physical, and chemical properties without the influence of grain boundaries.

Crystal Structure and Orientation:

- Crystal System: Hexagonal close-packed (HCP)

- Space Group: P6₃/mmc (No. 194)

- Lattice Parameters:

- a = 3.2094 Å

- c = 5.2100 Å

- c/a Ratio: ~1.624

- Density: 1.74 g/cm³

- Available Surface Orientations:

- (0001) Basal plane

- (10-10) Prism plane

- (11-20) Prism plane

- Custom orientations and specific miscut angles can be provided upon request.

Key Properties and Advantages:

- Lightest Structural Metal: Exceptionally low density for weight-sensitive applications

- Excellent Specific Strength: High strength-to-weight ratio

- Anisotropic Mechanical Properties: Ideal for deformation and slip system studies

- High Ductility at Elevated Temperatures: Improved formability in warm/hot conditions

- Good Machinability: Easier to process compared to other metals

- High Thermal Conductivity: Facilitates efficient heat dissipation

- Superior Homogeneity: Enables reproducible experimental results

- Corrosion Sensitivity: Useful for corrosion research and protective coating studies

Typical Applications:

- Fundamental studies on plastic deformation and slip mechanisms

- Material science and metallurgical research

- Lightweight structural material research

- Corrosion behavior investigations

- Thermal management materials

- Thin film deposition substrates

- Study of mechanical anisotropy and texture development

- Model material for dislocation dynamics and recrystallization studies

Specifications:

| Purity | ≥99.99% |

| Orientation Accuracy | ±0.5° (higher precision available) |

| Thickness Tolerance | ±0.05 mm |

| Surface Finish | Mechanical polish / CMP polish |

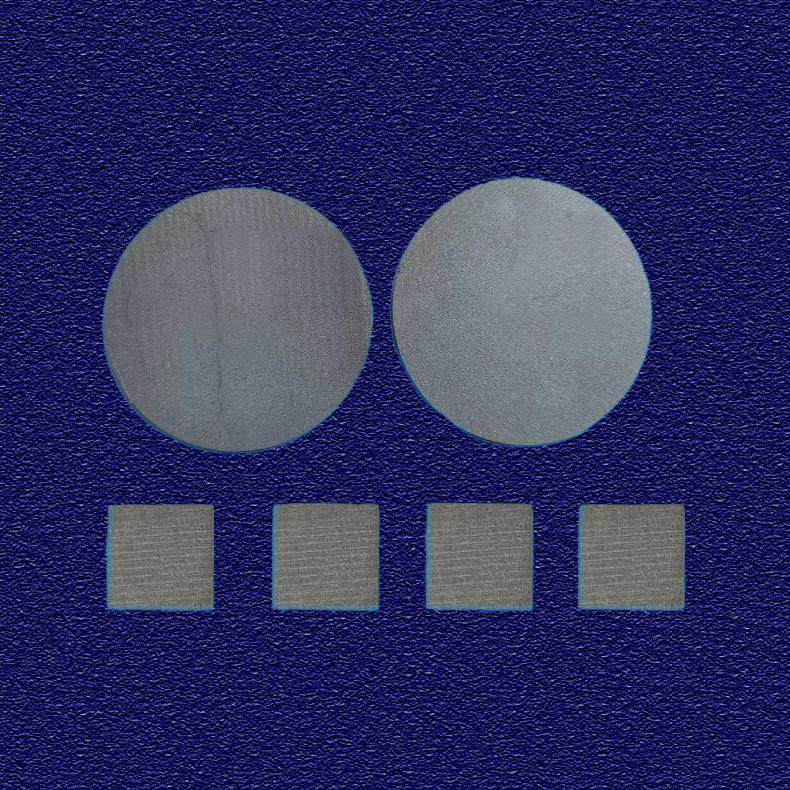

| Available Sizes | 5×5mm, 10×10mm, Ø1″, Ø2″, Ø3″, custom |

| Surface Orientations | (0001), (10-10), (11-20), custom |

| Packaging | Vacuum sealed in Class 100 cleanroom packaging |

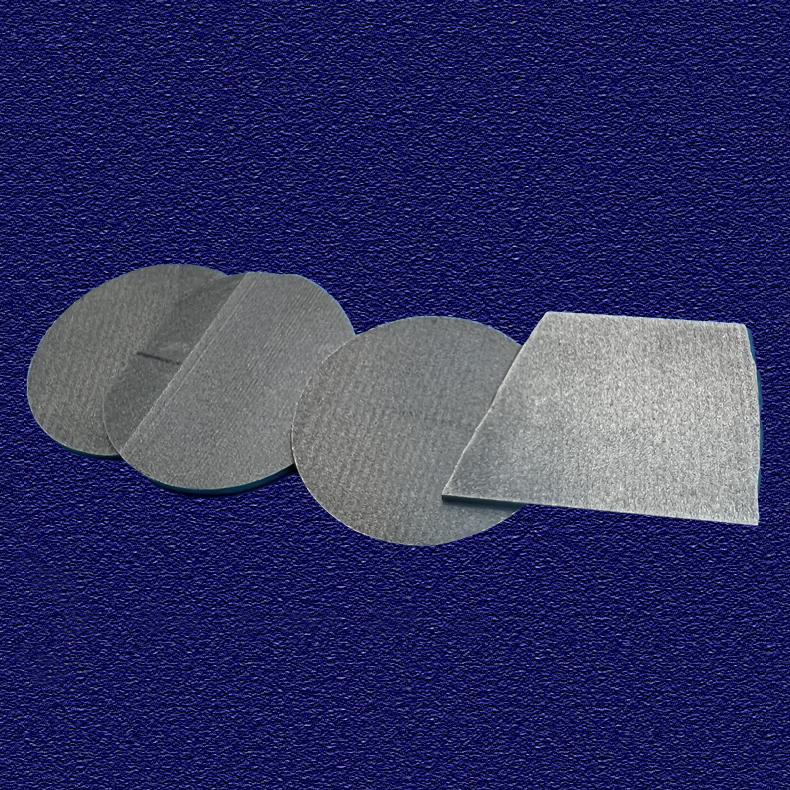

We offer both single-side polished, double-side polished, and as-cut (unpolished) options based on your specific application needs.

Available Sizes and Customization:

- Square substrates: 5×5mm, 10×10mm, 20×20mm

- Round wafers: Ø25.4mm (1″), Ø50.8mm (2″), Ø76.2mm (3″)

- Thickness: Typically 0.3mm to 2.0mm, customizable upon request

- Customization Options:

- Specific crystallographic orientations or miscut angles

- Custom thickness and surface finishes

- Surface roughening or polishing to specific Ra values

- Laser marking or backside grooving

We also provide special heat treatments or annealing upon customer request to achieve desired microstructural properties.

Quality Assurance:

Every magnesium single crystal is subject to rigorous quality control:

- X-ray Laue diffraction analysis to confirm crystal orientation and integrity

- High-purity analysis by glow discharge mass spectrometry (GDMS)

- Surface roughness evaluation by atomic force microscopy (AFM)

- Visual and optical inspection under cleanroom standards

- Dimensional accuracy verification using precision metrology

- Full traceability and certification with every batch

All products are processed, handled, and packaged in ISO Class 100 cleanroom environments to ensure contamination-free delivery.

Why Choose Our Magnesium (Mg) Single Crystals?

- Ultra-lightweight material ideal for structural and scientific studies

- Precise crystallographic orientation control for specialized research

- High-purity crystals with superior surface quality

- Wide range of standard sizes and complete customization support

- Fast production lead time and flexible ordering options

- Experienced technical support for deformation, corrosion, and optical studies

Ordering & Contact Information:

We offer flexible MOQ (Minimum Order Quantity) and competitive pricing. Our substrates are packaged in Class 100 cleanroom environments and shipped worldwide. For custom orders or technical inquiries, please contact us for a detailed consultation!