Neodymium Calcium Aluminum Oxide (NdCaAlO4, NCAO) Single Crystal Substrates

- Excellent Thermal Stability: Maintains crystal integrity at high operating temperatures.

- Good Chemical Resistance: Resists degradation in acidic and basic environments.

- Low Lattice Mismatch: Ideal for the epitaxial growth of complex oxides and superconducting films.

- High Mechanical Strength: Reduces risk of cracking during processing and device operation.

- Superior Surface Quality: Supports high-quality thin film deposition.

- Perovskite-like Structure: Compatible with a broad range of oxide thin films.

- Stable Optical Properties: Suitable for use in optical communication and laser components.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

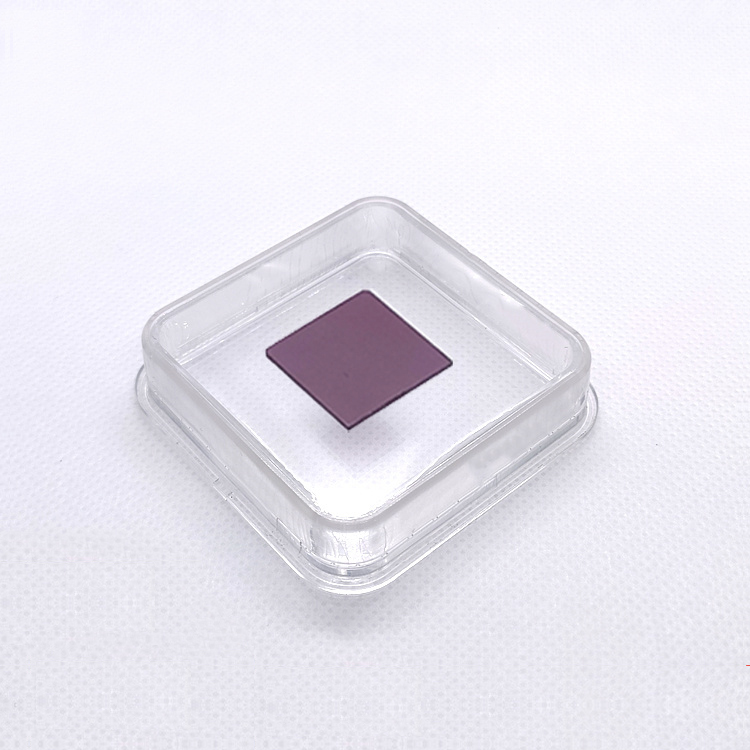

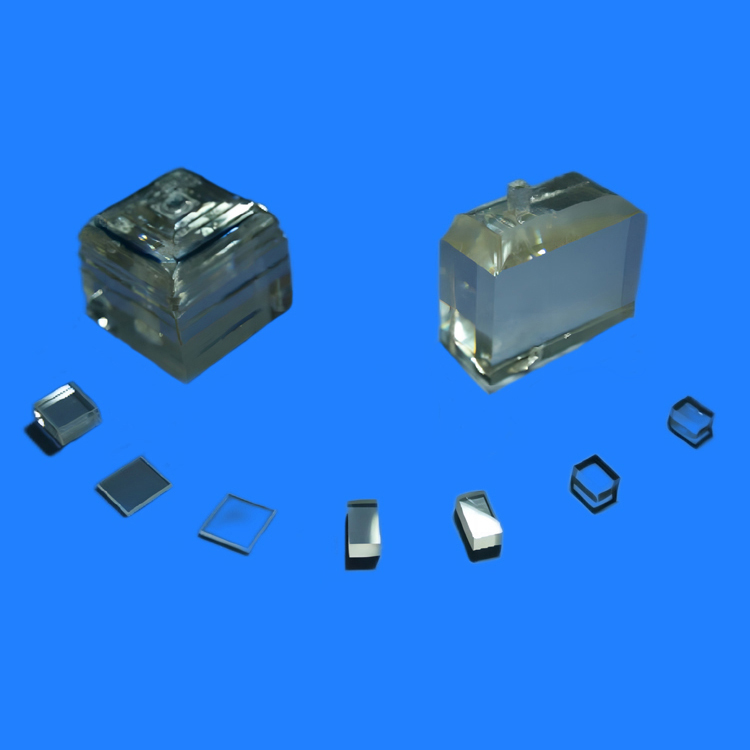

Neodymium Calcium Aluminum Oxide (NdCaAlO₄, commonly abbreviated as NCAO) single crystal substrates are recognized for their stable crystal structure, excellent thermal and chemical properties, and compatibility with perovskite-type epitaxial thin film growth.

NCAO substrates are widely utilized in high-performance laser devices, optical systems, and research in novel functional materials, particularly where high-temperature and chemically stable materials are required.

We offer premium-grade NCAO substrates with customizable sizes, orientations, and surface treatments to support a wide range of advanced optical and electronic applications.

Crystal Structure and Orientation:

- Chemical Formula: NdCaAlO₄

- Crystal Structure: Tetragonal (K₂NiF₄-type structure)

- Space Group: I4/mmm

- Lattice Constants:

- a = 3.68 Å

- c = 12.67 Å

- Density: ~6.1 g/cm³

- Melting Point: ~1860°C

- Thermal Expansion Coefficient: ~10.4 × 10⁻⁶/K (along a-axis)

- Available Orientations:

- (001), (110), (100) planes

- Other customized orientations upon request

Key Properties and Advantages:

- Excellent Thermal Stability: Maintains crystal integrity at high operating temperatures.

- Good Chemical Resistance: Resists degradation in acidic and basic environments.

- Low Lattice Mismatch: Ideal for the epitaxial growth of complex oxides and superconducting films.

- High Mechanical Strength: Reduces risk of cracking during processing and device operation.

- Superior Surface Quality: Supports high-quality thin film deposition.

- Perovskite-like Structure: Compatible with a broad range of oxide thin films.

- Stable Optical Properties: Suitable for use in optical communication and laser components.

Typical Applications:

- Epitaxial substrates for perovskite oxides and superconducting films

- Laser host materials and solid-state lasers

- Optical coatings and optoelectronic devices

- Research and development of ferroelectric and piezoelectric materials

- Microwave and high-frequency devices

- Thin film deposition for functional oxide materials

- Spintronic devices and quantum material research

Specifications:

| Diameter | 10 mm – 50.8 mm (customizable) |

| Thickness | 0.3 mm – 1.0 mm |

| Orientation | (001), (110), (100), custom available |

| Surface Finish | Single-side or double-side polished |

| Surface Quality | 10-5, 20-10, or 40-20 Scratch-Dig |

| Flatness | λ/8 or better at 632.8 nm |

| Parallelism | <10 arc seconds |

| Purity | ≥99.99% (4N) NCAO |

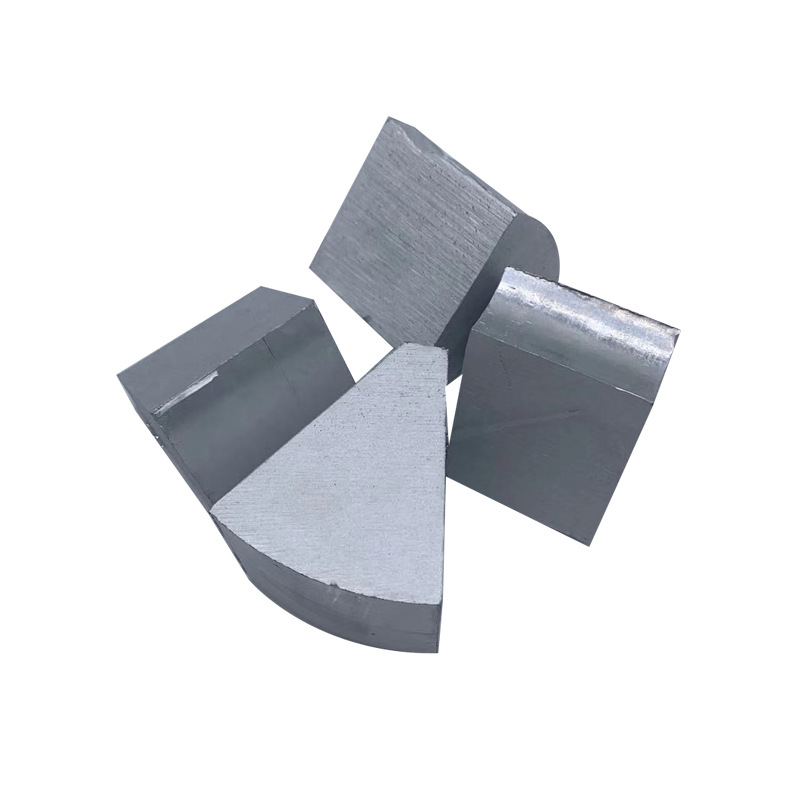

| Crystal Growth Method | Optical Floating Zone (OFZ) Method |

Available Sizes and Customization:

- Wafer Sizes: 10 mm, 20 mm, 25.4 mm (1 inch), 50.8 mm (2 inch), custom

- Thickness Options: 0.5 mm, 1.0 mm, or customized upon request

- Polishing Options:

- Single-Side Polished (SSP)

- Double-Side Polished (DSP)

- Orientation Tolerance: ±0.5°

- Edge Treatments: Chamfered, rounded, or customized designs

- Surface Roughness: ≤3 Å RMS upon request

- Additional Services:

- Pre-deposited buffer layers if needed

- Laser-marked orientation flats or notches

- Custom shapes like squares or rectangles

Quality Assurance:

Every NCAO substrate undergoes comprehensive testing and inspection to guarantee top performance:

- X-ray Diffraction (XRD) analysis to verify crystal quality

- Laue back-reflection for orientation verification

- Surface inspection using optical microscopes and AFM

- Thickness and flatness control with high-precision metrology

- Optical transmission measurements where applicable

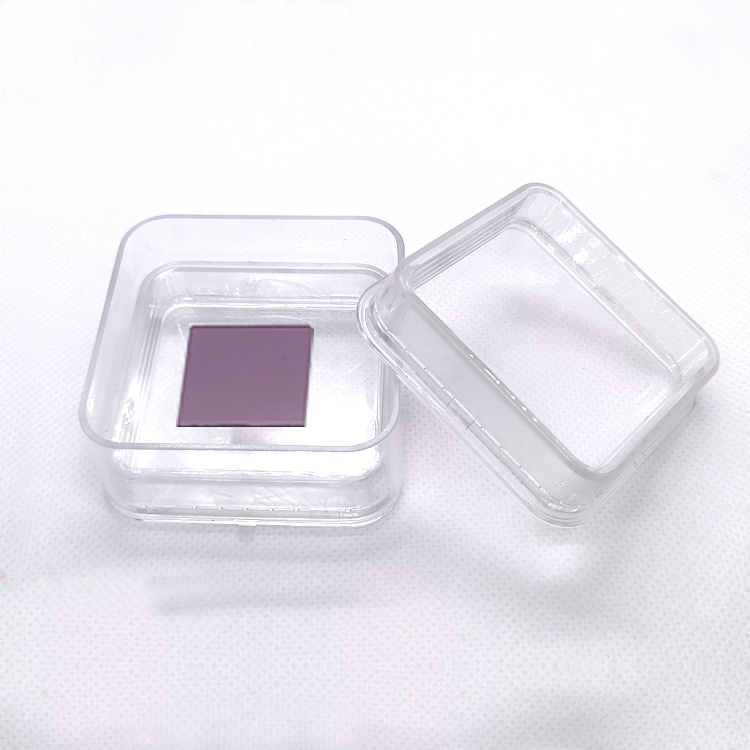

- Clean packaging in Class 1000 cleanroom environment

Why Choose Our NdCaAlO₄ (NCAO) Single Crystal Substrates?

- Consistently high-purity and low-defect single crystal material

- Wide range of customizable specifications tailored to your project

- Exceptional surface quality for critical thin film applications

- Expert support in material selection and application matching

- Strict quality control and comprehensive performance documentation

- Fast delivery and reliable customer service worldwide

Ordering & Contact Information:

We offer flexible MOQ (Minimum Order Quantity) and competitive pricing. Our substrates are packaged in Class 100 cleanroom environments and shipped worldwide. For custom orders or technical inquiries, please contact us for a detailed consultation!

KTN Crystal (KTa₀.₅Nb₀.₅O₃) – Orientation, 10 × 10 × 0.5 mm

KTN Crystal (KTa₀.₅Nb₀.₅O₃) – Orientation, 10 × 10 × 0.5 mm