Nickel (Ni) Single Crystal Substrates

- Excellent Mechanical Strength: Suitable for high-stress applications

- Good Thermal Conductivity: Facilitates high-temperature processing

- Corrosion Resistance: Stable in oxidizing and reducing environments

- High Crystallinity: Supports high-quality epitaxial growth

- Magnetic Properties: Useful for spintronics and magnetic studies

- Surface Stability: Ideal for ultra-high vacuum (UHV) surface science experiments

- Customizable: Wide range of sizes, orientations, and surface finishes

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Nickel (Ni) single crystal substrates are precision-engineered materials with a well-defined crystallographic orientation. Thanks to their excellent mechanical strength, corrosion resistance, high thermal stability, and magnetic properties, Ni single crystals are widely used for thin film deposition, catalysis studies, magnetic thin film research, and surface science investigations. Nickel substrates serve as essential platforms for the epitaxial growth of metallic and oxide films, helping researchers to understand fundamental surface phenomena and material behaviors at the atomic level.

Crystal Structure and Orientation:

- Chemical Formula: Ni

- Crystal System: Face-Centered Cubic (FCC)

- Space Group: Fm-3m (No. 225)

- Lattice Constant: a = 3.524 Å

- Melting Point: 1455 °C

- Density: 8.908 g/cm³

- Available Surface Orientations:

- (100)

- (110)

- (111)

- Custom orientations and miscut angles available upon request

- Miscut Angle Options:

- Standard miscut ±0.5°

- Custom miscut angles available (e.g., 2°, 5°)

Key Properties and Advantages:

- Excellent Mechanical Strength: Suitable for high-stress applications

- Good Thermal Conductivity: Facilitates high-temperature processing

- Corrosion Resistance: Stable in oxidizing and reducing environments

- High Crystallinity: Supports high-quality epitaxial growth

- Magnetic Properties: Useful for spintronics and magnetic studies

- Surface Stability: Ideal for ultra-high vacuum (UHV) surface science experiments

- Customizable: Wide range of sizes, orientations, and surface finishes

Typical Applications:

- Epitaxial growth of metals and oxides (e.g., Cu, Co, Fe, NiO)

- Surface science and catalytic reaction studies

- Magnetic thin film research and spintronic device development

- Growth of graphene and 2D materials

- Investigations of oxidation processes and corrosion mechanisms

- Thin film magneto-resistive sensors

- Metal-insulator-metal (MIM) structure research

- Template substrates for complex heterostructures

Specifications:

| Purity | ≥99.99% (4N) |

| Orientation Accuracy | ±0.5° (higher precision available) |

| Thickness Tolerance | ±0.02 mm |

| Surface Finish | Single-side polished (SSP) or double-side polished (DSP) |

| Surface Roughness (Ra) | <0.5 nm (depending on polishing) |

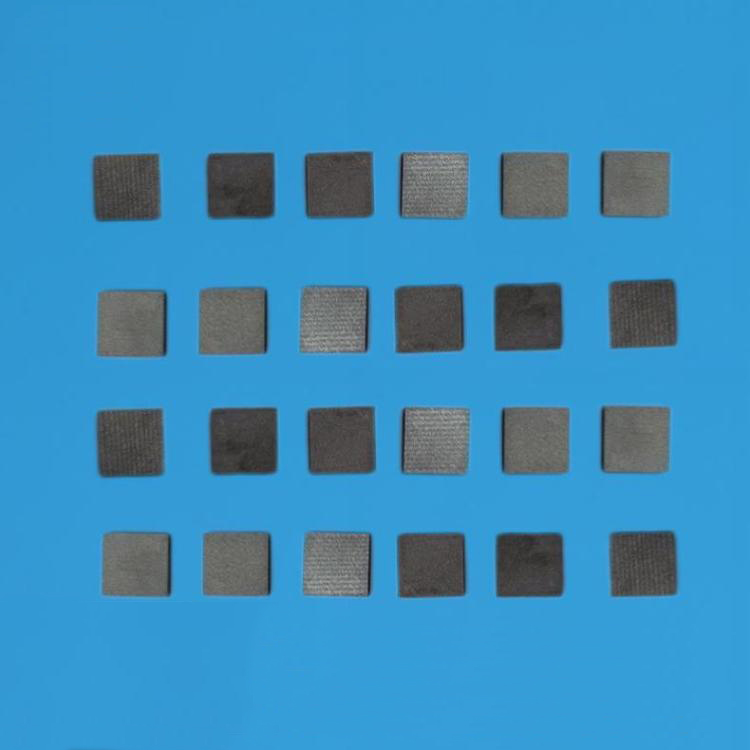

| Size Range | 10×10mm, 15×15mm, 20×20mm, Ø1″, Ø2″ (custom sizes available) |

| Surface Orientations | (100), (110), (111), custom |

| Packaging | Class 100 cleanroom vacuum sealed |

Available Sizes and Customization:

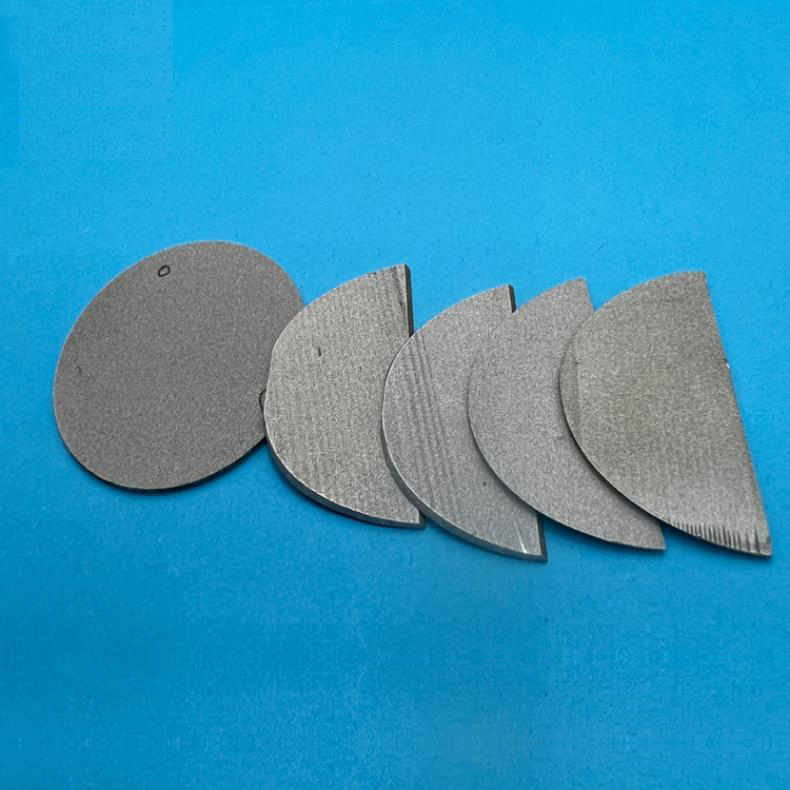

- Square substrates: 10×10mm, 15×15mm, 20×20mm, 5×5mm, custom

- Round wafers: Ø25.4mm (1 inch), custom

- Thickness options: 0.5mm, 1.0mm (other thicknesses available)

- Surface Options:

- Single-side polished (SSP)

- Double-side polished (DSP)

- Customization:

- Special crystallographic orientations

- Defined miscut angles

- Ultra-thin or thick substrates

- Special edge treatments (e.g., beveling, chamfering)

We offer flexible solutions tailored to your research or production needs.

Quality Assurance:

All Nickel single crystal substrates are manufactured under strict quality control:

- Orientation verified by X-ray Laue back reflection or high-resolution X-ray diffraction (HRXRD)

- Surface roughness checked by Atomic Force Microscopy (AFM) or Profilometer

- Dimensional accuracy ensured by precision metrology

- Purity verified by Glow Discharge Mass Spectrometry (GDMS)

- Visual inspection under cleanroom conditions for scratches, cracks, and surface defects

- Vacuum-sealed in a Class 100 cleanroom for maximum cleanliness and protection

Each product is supplied with a full Certificate of Analysis (CoA) upon delivery.

Why Choose Our Nickel Single Crystal Substrates?

- High purity and perfect crystallinity for demanding applications

- Wide range of standard and custom sizes/orientations

- Consistently smooth, defect-free surfaces

- Rapid delivery times with flexible customization options

- Professional technical consultation and responsive service

- Competitive pricing with uncompromised quality

Ordering & Contact Information:

We offer flexible MOQ (Minimum Order Quantity) and competitive pricing. Our substrates are packaged in Class 100 cleanroom environments and shipped worldwide. For custom orders or technical inquiries, please contact us for a detailed consultation!