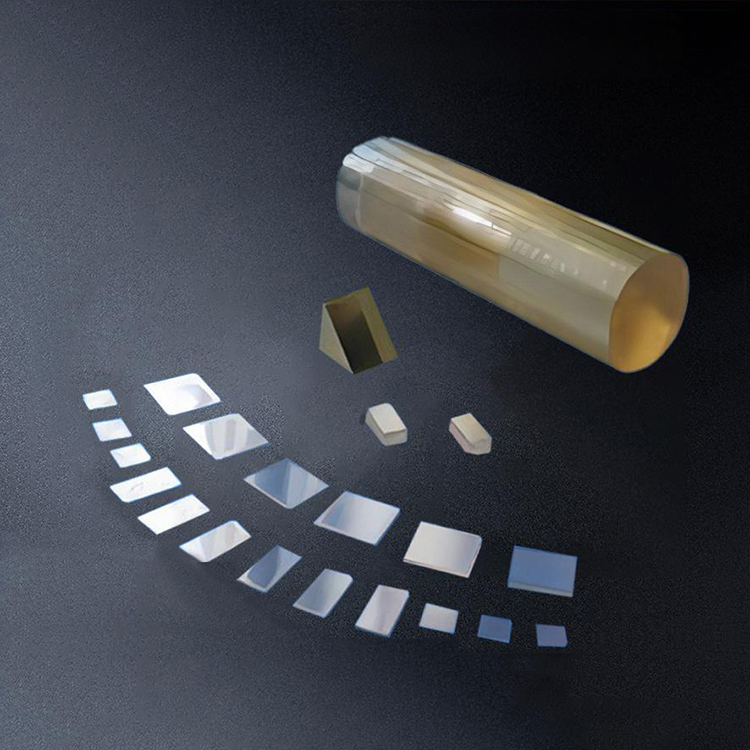

Titanium Dioxide (TiO2) Single Crystal Substrates

- High Refractive Index: Ideal for optical coatings and photonic crystals.

- Wide Bandgap: Suitable for ultraviolet photodetectors and photocatalysis.

- Strong Birefringence: Enhances nonlinear optical effects and polarization control.

- Excellent Chemical Stability: Resistant to acids and alkalis under normal conditions.

- High Dielectric Constant: Beneficial for high-k dielectric applications in electronics.

- Superior Optical Transparency: From visible to mid-infrared wavelengths.

- Mechanical Strength: Supports demanding manufacturing and processing.

- Suitable for Epitaxial Growth: Template for oxide thin films such as perovskites.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Titanium Dioxide (TiO₂) single crystal substrates are widely used in photonic, electronic, and optical applications due to their exceptional dielectric properties, high refractive index, wide bandgap, and strong birefringence. TiO₂ crystals are available mainly in two forms for substrate use: Rutile phase (tetragonal structure) and Anatase phase (also tetragonal but different properties).

Rutile TiO₂ single crystals, in particular, exhibit superior optical performance, making them ideal for use in photonic devices, waveguides, nonlinear optics, and epitaxial growth of functional oxide thin films.

We provide high-quality TiO₂ single crystal wafers and substrates to meet a variety of research and industrial needs.

Crystal Structure and Orientation:

- Chemical Formula: TiO₂

- Crystal System: Tetragonal (Rutile or Anatase Phase)

- Lattice Constants (Rutile): a = 4.593 Å, c = 2.959 Å

- Transparency Range: 400 nm to 5 μm (varies slightly depending on phase)

- Refractive Index: ~2.5–2.9 (at visible wavelengths)

- Bandgap: ~3.0 eV (Rutile), ~3.2 eV (Anatase)

- Density: 4.25 g/cm³ (Rutile), 3.89 g/cm³ (Anatase)

- Hardness (Mohs): 6

- Available Orientations:

- (100), (110), (001) for Rutile TiO₂

- (001) for Anatase TiO₂

- Customized orientations available upon request for specific epitaxial growth requirements.

Key Properties and Advantages:

- High Refractive Index: Ideal for optical coatings and photonic crystals.

- Wide Bandgap: Suitable for ultraviolet photodetectors and photocatalysis.

- Strong Birefringence: Enhances nonlinear optical effects and polarization control.

- Excellent Chemical Stability: Resistant to acids and alkalis under normal conditions.

- High Dielectric Constant: Beneficial for high-k dielectric applications in electronics.

- Superior Optical Transparency: From visible to mid-infrared wavelengths.

- Mechanical Strength: Supports demanding manufacturing and processing.

- Suitable for Epitaxial Growth: Template for oxide thin films such as perovskites.

Typical Applications:

- Optical waveguides and photonic devices

- Laser optics and nonlinear optical systems

- UV and visible range detectors and sensors

- Epitaxial growth of complex oxides (e.g., ferroelectric or multiferroic materials)

- High-k dielectric materials for advanced electronics

- Photocatalytic materials development

- Photonic crystals and metamaterials

- Advanced optical coatings

- Heterostructure research in material science

Specifications:

| Diameter | 10 mm – 50.8 mm (2 inch) (others on request) |

| Thickness | 0.2 mm – 1.0 mm (custom options available) |

| Orientation | (100), (110), (001) (Rutile); (001) (Anatase) |

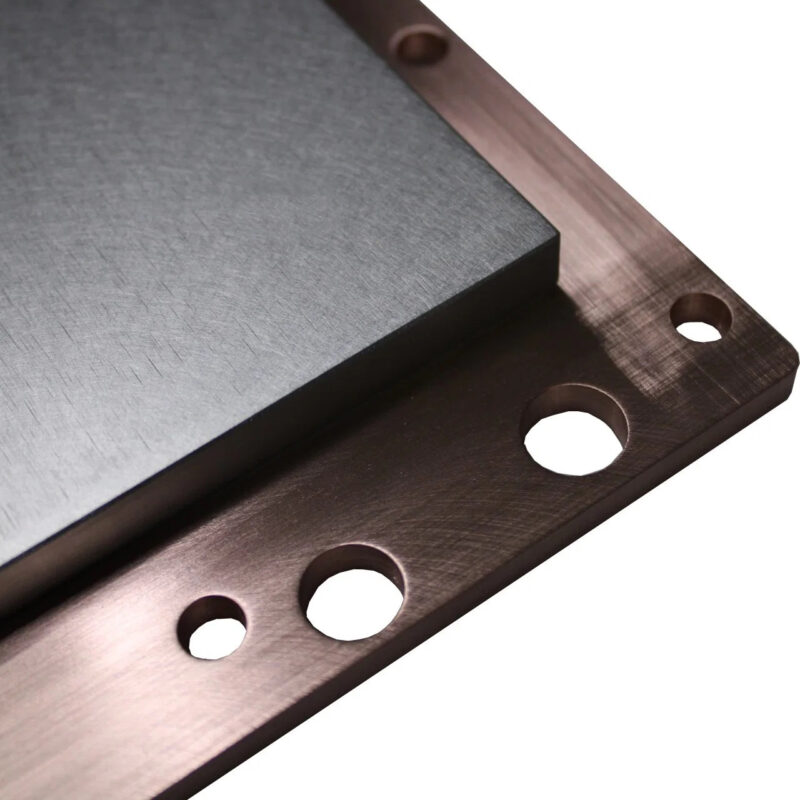

| Surface Finish | Single-side or double-side polished |

| Surface Quality | 10-5 Scratch-Dig or better (MIL-PRF-13830B) |

| Surface Flatness | λ/8 or better @ 632.8 nm |

| Parallelism | <10 arc seconds |

| Edge Treatment | Beveled or as-cut |

| Purity | >99.99% (4N) or higher |

| Coating Options | Custom Anti-Reflection (AR) coatings optional |

Available Sizes and Customization:

- Wafer Sizes: 10 mm, 20 mm, 25 mm, 1 inch (25.4 mm), 2 inch (50.8 mm), custom

- Thickness: 0.2 mm, 0.5 mm, 1.0 mm, or customized

- Polishing Options:

- Single-Side Polished (SSP)

- Double-Side Polished (DSP)

- Orientation Accuracy: ±0.5° or tighter based on application needs

- Special Treatments:

- Ultra-low surface roughness

- Super-polished mirror finish

- Customization: Orientation, thickness, surface roughness, diameter, coatings, and special requirements can all be tailored.

Quality Assurance:

All TiO₂ substrates undergo strict quality control procedures:

- High-Resolution X-ray Diffraction (HRXRD) for crystal quality analysis

- Optical Transmission Testing

- Atomic Force Microscopy (AFM) for surface roughness measurement

- Surface Flatness Testing by Interferometry

- Visual Inspection under Microscopy for defects

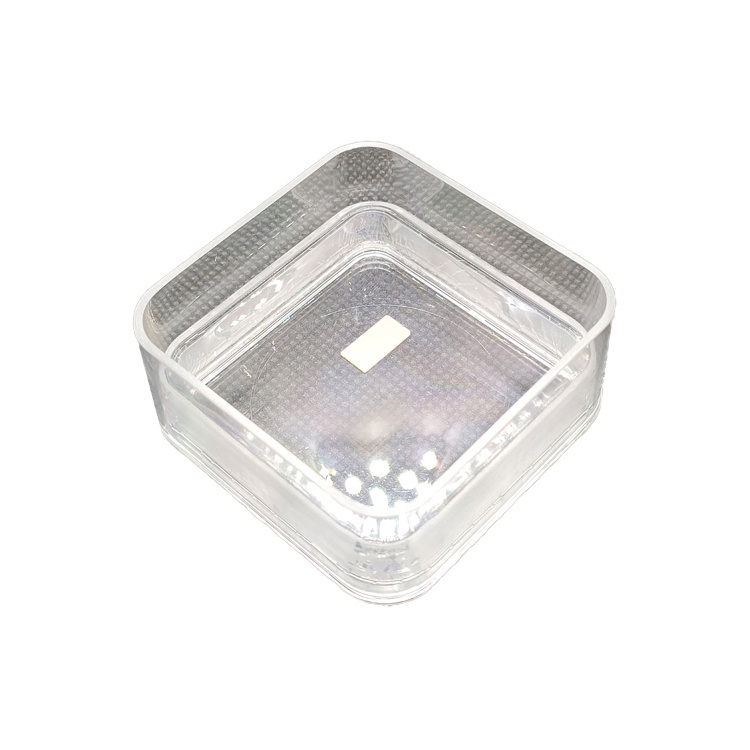

- Cleanroom-level packaging to prevent contamination

Why Choose Our Titanium Dioxide (TiO₂) Substrates?

- Premium-quality Rutile and Anatase TiO₂ single crystals

- Flexible customization in orientation, size, thickness, and surface quality

- Superior optical, mechanical, and chemical properties

- Fast production cycles and global delivery

- Dedicated technical support and consultation services

- Proven experience supplying universities, research institutes, and industry leaders

Ordering & Contact Information:

We offer flexible MOQ (Minimum Order Quantity) and competitive pricing. Our substrates are packaged in Class 100 cleanroom environments and shipped worldwide. For custom orders or technical inquiries, please contact us for a detailed consultation!