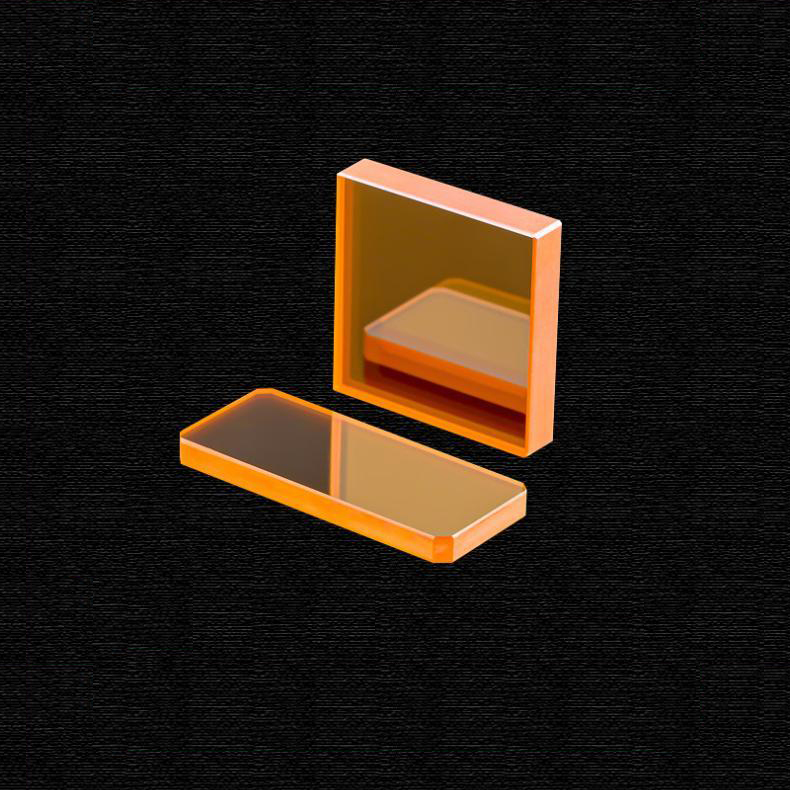

Zinc Selenide (ZnSe) Single Crystal Substrates

- Broad Infrared Transmission: Covers visible to far-IR regions (0.5–22 μm).

- High Refractive Index: Suitable for focusing and imaging applications.

- Low Bulk Absorption: Enables high-power CO₂ laser operation.

- Excellent Thermal Shock Resistance: Suitable for high-power, high-temperature environments.

- Chemical Stability: Resistant to moisture and most chemicals in ambient environments.

- Isotropic Optical Properties: Minimal birefringence effects.

- High Damage Threshold: Ideal for high-power laser optics and windows.

- Good Mechanical Strength: Though softer than sapphire, sufficient for most optical setups.

- Compatible with Anti-Reflection (AR) and Protective Coatings: Enhances performance and durability.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Zinc Selenide (ZnSe) single crystal substrates are widely used in infrared optics, photonics, and laser systems due to their excellent infrared transparency, low absorption, and broad transmission range from the visible to the far-infrared (0.5–22 µm).

ZnSe substrates are particularly valued for their high refractive index, low bulk absorption, and chemical stability, making them ideal for CO₂ laser optics, thermal imaging systems, infrared spectroscopy, and other high-performance IR applications.

We offer high-purity, low-defect ZnSe single crystal substrates with customizable specifications to meet research and industrial requirements.

Crystal Structure and Orientation:

- Chemical Formula: ZnSe

- Crystal Structure: Cubic (Zinc Blende structure)

- Lattice Constant: a = 5.667 Å

- Transparency Range: 0.5 μm to 22 μm

- Refractive Index: ~2.4 at 10.6 μm

- Density: 5.27 g/cm³

- Hardness (Knoop): ~120 kg/mm²

- Thermal Expansion Coefficient: 7.57 × 10⁻⁶ /K

- Melting Point: ~1525°C

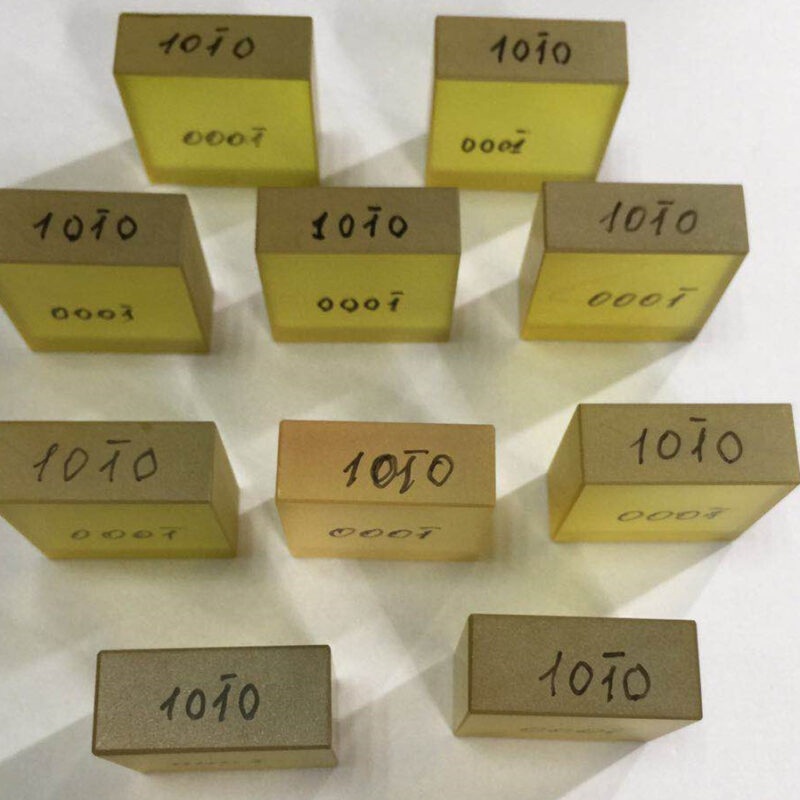

- Available Orientations:

- <100>, <110>, <111>

- Other orientations available upon request.

Key Properties and Advantages:

- Broad Infrared Transmission: Covers visible to far-IR regions (0.5–22 μm).

- High Refractive Index: Suitable for focusing and imaging applications.

- Low Bulk Absorption: Enables high-power CO₂ laser operation.

- Excellent Thermal Shock Resistance: Suitable for high-power, high-temperature environments.

- Chemical Stability: Resistant to moisture and most chemicals in ambient environments.

- Isotropic Optical Properties: Minimal birefringence effects.

- High Damage Threshold: Ideal for high-power laser optics and windows.

- Good Mechanical Strength: Though softer than sapphire, sufficient for most optical setups.

- Compatible with Anti-Reflection (AR) and Protective Coatings: Enhances performance and durability.

Typical Applications:

- High-power CO₂ laser optics (windows, lenses, beam expanders)

- Thermal imaging systems and FLIR cameras

- Infrared spectroscopy (FTIR windows)

- Night vision and IR sensors

- Beam splitters, prisms, and filters for infrared systems

- Optical components for aerospace and defense applications

- Substrates for infrared thin film deposition

- Medical laser systems

Specifications:

| Diameter | 10 mm – 100 mm or customized |

| Thickness | 0.2 mm – 5.0 mm |

| Orientation | <100>, <110>, <111> |

| Surface Finish | Single-side or double-side polished |

| Surface Quality | 20-10 or 40-20 Scratch-Dig (per MIL-PRF-13830B) |

| Flatness | λ/10 at 632.8 nm |

| Parallelism | <10 arc seconds |

| Clear Aperture | >90% of the diameter |

| Purity | ≥99.999% (5N) ZnSe single crystal |

| Coating Options | AR coating for 3-5 μm, 8-12 μm, or customized |

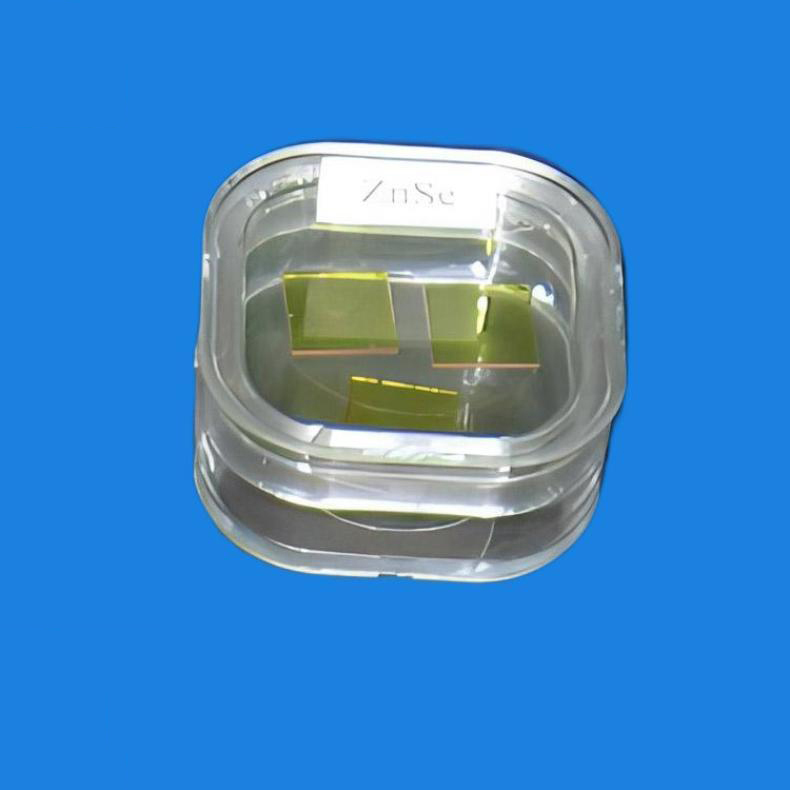

Available Sizes and Customization:

- Wafer Sizes: 10 mm, 20 mm, 25 mm (1 inch), 50.8 mm (2 inch), up to 100 mm, custom

- Thickness: Typically 0.5 mm, 1.0 mm, 2.0 mm; other thicknesses available

- Polishing Options:

- Single-Side Polished (SSP)

- Double-Side Polished (DSP)

- Orientation Precision: ±0.5° or tighter

- Surface Roughness: <3 Å (atomic-level polish available)

- Special Treatments:

- Protective overcoats

- Custom AR or DLC coatings for enhanced laser durability

- Custom Services: Laser marking, special shapes (squares, rectangles), drilled holes, edge beveling.

Quality Assurance:

All ZnSe substrates go through strict and standardized quality control processes:

- X-Ray Diffraction (XRD) for crystalline quality verification

- FTIR spectrophotometry for transmission testing

- Surface roughness analysis using AFM

- Interferometric flatness testing

- Inspection for scratches, pits, inclusions, and defects

- Cleanroom-class packaging (Class 100/1000 cleanrooms)

Why Choose Our Zinc Selenide (ZnSe) Substrates?

- High-purity, defect-free ZnSe crystals for top optical performance

- Flexible customization of size, thickness, orientation, and coatings

- Outstanding infrared transmission and thermal stability

- Fast turnaround and consistent product quality

- Global supply capability with technical consulting support

- Serving research, defense, medical, aerospace, and laser industries

Ordering & Contact Information:

We offer flexible MOQ (Minimum Order Quantity) and competitive pricing. Our substrates are packaged in Class 100 cleanroom environments and shipped worldwide. For custom orders or technical inquiries, please contact us for a detailed consultation!