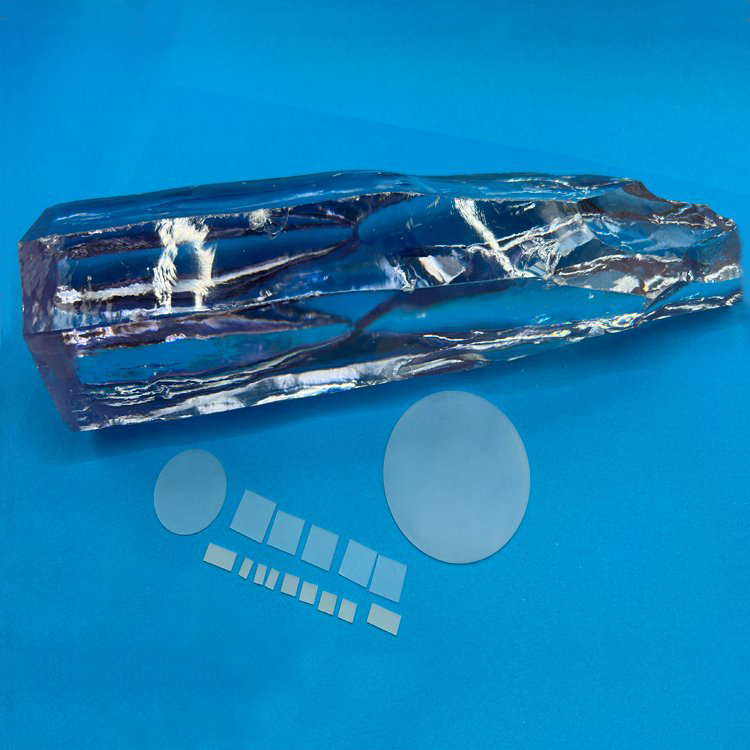

Zirconia (ZrO2) Single Crystal Substrates

- High Thermal Stability: Outstanding resistance to high temperatures up to 2500°C.

- Exceptional Mechanical Properties: High hardness, high fracture toughness, and high wear resistance.

- Excellent Ionic Conductivity: Suitable for solid oxide fuel cell (SOFC) applications.

- Low Thermal Conductivity: Ideal for thermal barrier coatings.

- Wide Optical Transmission Range: Transparent from visible to mid-IR (approximately 0.3 – 5 μm depending on doping and phase).

- Chemical Resistance: Highly resistant to corrosion, oxidation, and chemical attack.

- Various Crystal Phases Available: Including cubic-stabilized zirconia (YSZ) and tetragonal zirconia.

Custom products or bulk orders, please contact us for competitive pricing!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Zirconia (ZrO₂) single crystal substrates are highly valued for their excellent mechanical strength, high fracture toughness, superior thermal stability, and outstanding ionic conductivity. These substrates are widely used in high-temperature electronics, solid oxide fuel cells (SOFCs), oxygen sensors, ferroelectric thin films, and advanced optical applications. Our ZrO₂ single crystal wafers are grown with precise control to ensure excellent structural integrity, low defect density, and superior surface quality.

Key Features and Properties:

- High Thermal Stability: Outstanding resistance to high temperatures up to 2500°C.

- Exceptional Mechanical Properties: High hardness, high fracture toughness, and high wear resistance.

- Excellent Ionic Conductivity: Suitable for solid oxide fuel cell (SOFC) applications.

- Low Thermal Conductivity: Ideal for thermal barrier coatings.

- Wide Optical Transmission Range: Transparent from visible to mid-IR (approximately 0.3 – 5 μm depending on doping and phase).

- Chemical Resistance: Highly resistant to corrosion, oxidation, and chemical attack.

- Various Crystal Phases Available: Including cubic-stabilized zirconia (YSZ) and tetragonal zirconia.

Typical Applications:

- Substrates for thin-film deposition (ferroelectrics, piezoelectrics)

- Solid oxide fuel cells (SOFC) electrolyte materials

- High-temperature oxygen sensors

- Protective coatings for aerospace and turbine industries

- Thermal barrier coatings (TBCs)

- Laser host materials (when doped with rare-earth ions)

- Optical windows and advanced ceramic components

- Catalytic applications

Specifications:

| Chemical Formula | ZrO₂ |

| Crystal Structure | Cubic (stabilized), monoclinic, tetragonal |

| Density | ~5.68 g/cm³ |

| Melting Point | ~2715°C |

| Thermal Expansion Coefficient | ~10.3 × 10⁻⁶ /K |

| Optical Transmission Range | 0.3 – 5 μm |

| Hardness | ~1200 – 1400 HV |

| Fracture Toughness | ~5 – 10 MPa·m¹ᐟ² |

| Dielectric Constant | ~25 @ 1 MHz |

| Surface Quality | 20/10 Scratch/Dig |

| Surface Flatness | <λ/10 @ 632.8 nm |

| Available Orientations | (100), (110), (111) |

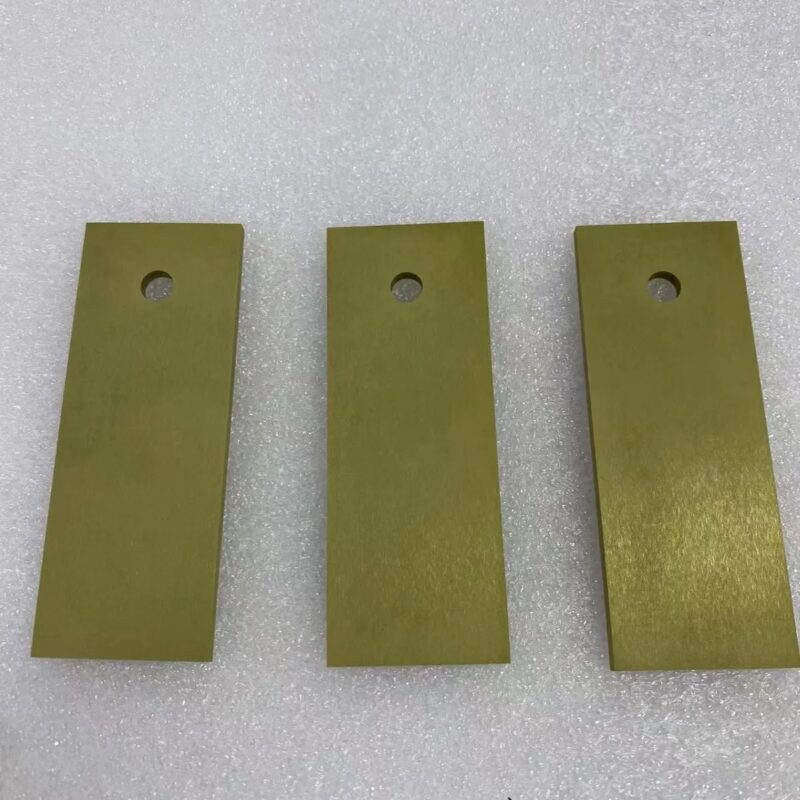

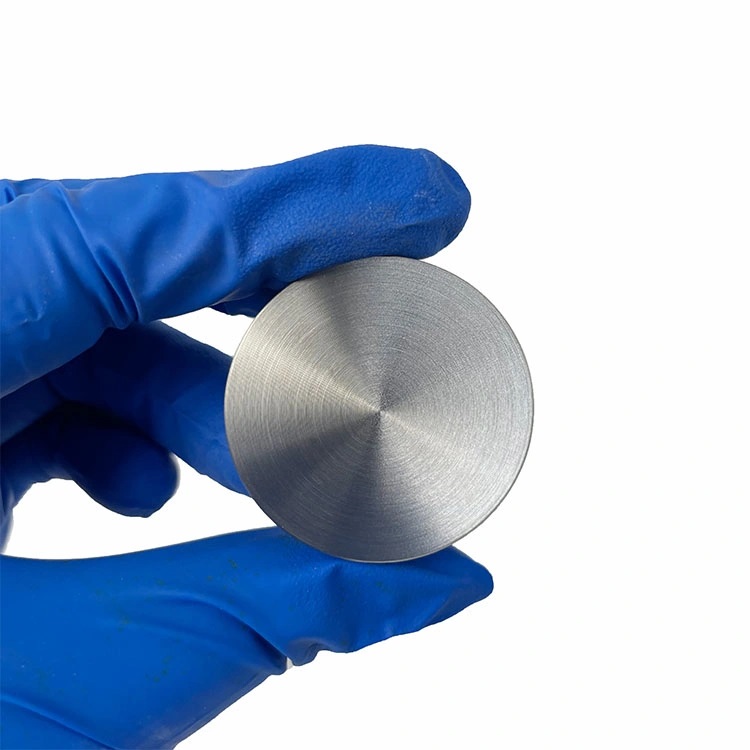

| Available Wafer Sizes | 5×5 mm², 10×10 mm², 1″, 2″, 3″ |

| Thickness Range | 0.5 mm – 2.0 mm |

| Surface Finish | SSP or DSP |

| Doping | YSZ (8 mol% Y₂O₃) or others optional |

Material Properties and Crystal Structure:

- Chemical Formula: ZrO₂

- Crystal Structure: Cubic (fluorite type for stabilized ZrO₂), monoclinic, or tetragonal depending on stabilization

- Space Group: Fm-3m (cubic phase)

- Lattice Constant: ~5.09 Å (cubic)

- Density: ~5.68 g/cm³

- Melting Point: ~2715°C

- Thermal Expansion Coefficient: ~10.3 × 10⁻⁶ /K

- Optical Transmission Range: ~0.3–5 μm (varies slightly depending on stabilization/dopants)

- Hardness: ~1200–1400 HV (Vickers hardness)

- Fracture Toughness: ~5–10 MPa·m¹ᐟ²

- Dielectric Constant: ~25 at 1 MHz

- Ionic Conductivity: High at elevated temperatures (especially YSZ)

Standard Product Sizes and Availability:

- Standard wafer sizes: 5×5 mm², 10×10 mm², 20×20 mm², 1-inch, 2-inch, 3-inch

- Thickness: 0.5 mm, 1.0 mm, 2.0 mm (customizable)

- Orientation: (100), (110), (111) or custom orientations

- Surface Finishing: Single Side Polished (SSP) or Double Side Polished (DSP)

- Surface Quality: 20/10 or better (MIL-PRF-13830B)

- Surface Flatness: <λ/10 @ 632.8 nm

- Edge treatment: Sawn or beveled upon request

- Available Types: Pure monoclinic ZrO₂, cubic-stabilized zirconia (e.g., 8 mol% Y₂O₃-stabilized ZrO₂, YSZ)

Customization Options:

- Doping options: Yttria-stabilized zirconia (YSZ), scandia-stabilized zirconia (ScSZ), and others

- Custom thickness, dimensions, and orientations

- Ultra-precision polishing to achieve lower roughness (<1 nm Ra)

- AR coatings for optical applications (optional)

- Special packaging for high-purity or vacuum requirements

- Pre-annealed wafers for enhanced stability

- Wafer dicing or laser cutting services available

Packaging and Delivery:

- Packaged in a Class 100 cleanroom environment

- Vacuum-sealed with desiccants to prevent moisture and particle contamination

- Cleanroom-grade containers used for shipping

- Lead time: 2–4 weeks for standard products; custom orders depend on specifications

- Complete documentation: Crystal orientation, polishing report, and material inspection reports available upon request

Why Choose Our Zirconia (ZrO2) Single Crystal Substrates?

- High-purity crystal growth with strict quality control

- Excellent surface quality, minimal defects, and precise orientation

- Wide range of standard and customized specifications

- Professional technical support and consultation

- Rapid response time and reliable global delivery

- ISO-certified quality management system ensuring consistent product performance

Ordering & Contact Information:

We offer flexible MOQ (Minimum Order Quantity) and competitive pricing. Our substrates are packaged in Class 100 cleanroom environments and shipped worldwide. For custom orders or technical inquiries, please contact us for a detailed consultation!