Showing 661–672 of 678 results

-

- Broad Optical Transmission: ZnSe offers high transmission from the visible to the IR range (0.6 µm to 16 µm), making it ideal for infrared optics and laser systems.

- High Laser Damage Threshold: ZnSe can withstand high-power laser radiation, making it a preferred material for CO₂ laser optics and other high-energy laser applications.

- Chemical and Thermal Stability: ZnSe is chemically stable and has good thermal shock resistance, ensuring reliable performance in challenging environments, such as thermal imaging and industrial laser systems.

- High Purity and Low Absorption: ZnSe sputtering targets are available in high purity (up to 99.999%), ensuring minimal absorption and optimal performance in optical coatings and laser optics.

-

- High purity (≥99.99%).

- Direct bandgap for superior optoelectronic performance.

- Excellent optical transparency in visible to infrared spectra.

- Uniform pellet size for consistent deposition results.

- Customizable pellet sizes and packaging for specific applications.

-

- Optoelectronic Properties: ZnTe is highly valued for its ability to efficiently emit light, making it a key material in optoelectronics and LEDs.

- High Purity: Available in various purity levels (99.9%, 99.99%, and higher) to ensure high-quality thin films.

- Thermal Stability: ZnTe maintains its properties under high-temperature conditions, making it suitable for high-performance applications.

- Customizable Sizes: Available in different diameters and thicknesses for a wide range of sputtering systems.

- Wide Application Range: Ideal for use in numerous industries, including renewable energy, communications, and infrared sensing.

-

- High Melting Point: Zirconium foil has a melting point of approximately 1855°C, making it ideal for high-temperature applications.

- Corrosion Resistance: Exceptional resistance to corrosion, particularly in acids, alkalis, and saltwater environments, making it highly durable in harsh conditions.

- Low Neutron Absorption: Ideal for use in nuclear reactors as it exhibits low neutron absorption, contributing to its application in nuclear fuel cladding.

- Thermal Stability: Maintains structural integrity even under extreme temperature conditions, making it suitable for use in high-heat environments.

- Malleability: The material is highly malleable, allowing it to be formed into thin sheets, foils, and complex shapes without compromising its performance.

- Lightweight and Strong: Zirconium foil offers a balance of low density and high strength, making it suitable for applications where both strength and lightness are required.

- Biocompatibility: Non-toxic and biocompatible, making it suitable for use in medical and pharmaceutical applications.

-

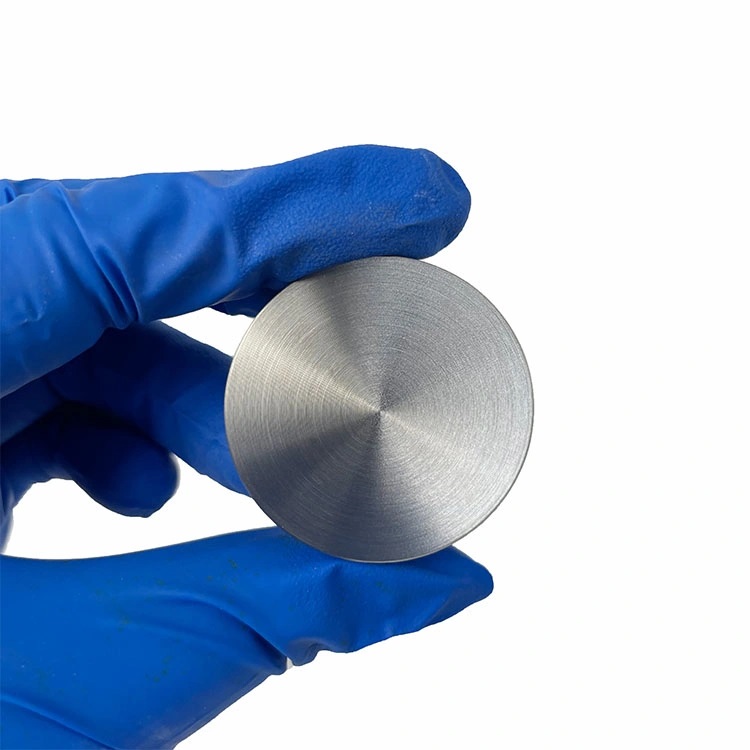

- High Purity: Zirconium pellets are available in high purity, typically ≥ 99.9%, ensuring reliable thin film deposition.

- Corrosion Resistance: Excellent resistance to corrosion, particularly in aggressive chemical environments.

- Thermal Stability: Zirconium’s high melting point (1,855°C) makes it suitable for high-temperature applications.

- Oxidation Resistance: Forms a stable oxide layer, improving the durability of films in reactive environments.

-

Zirconium sputtering targets are critical for industries that require materials with exceptional corrosion resistance, high-temperature stability, and biocompatibility, making them indispensable in electronics, aerospace, nuclear, and medical applications.

-

- High Hardness: ZrB₂ is an extremely hard material, making it ideal for wear-resistant and protective coatings.

- Thermal Stability: ZrB₂ sputtering targets produce thin films that can withstand high temperatures, making them suitable for use in harsh environments.

- High Thermal Conductivity: ZrB₂ has excellent thermal conductivity, which is advantageous for heat management in high-performance coatings.

- Chemical Resistance: ZrB₂ thin films are resistant to chemical attack, especially in high-temperature, corrosive environments.

-

- High Melting Point: ZrC has an extremely high melting point (~3,530°C), making it suitable for high-temperature applications.

- Excellent Hardness and Wear Resistance: It provides outstanding hardness, making it ideal for protective coatings and applications requiring high durability.

- Good Thermal and Electrical Conductivity: ZrC exhibits metallic-like conductivity, which is beneficial for electrical applications and high-heat environments.

- Corrosion and Oxidation Resistance: Highly resistant to chemical attack, corrosion, and oxidation, even in harsh conditions.

- Low Density: Compared to other refractory materials, ZrC has a relatively low density, making it advantageous in aerospace applications where weight is a critical factor.

-

- High Purity: Purity levels of ≥99% ensure reliability in critical applications.

- Thermal Stability: Exceptional resistance to oxidation and thermal shock.

- Superior Hardness: Ideal for cutting and wear-resistant tools.

- High Melting Point: Withstands extreme temperatures (~3540°C).

- Customizable Particle Sizes: Available in nano (<100 nm) and micro (1–50 µm) grades or customized.

-

- High Hardness: ZrC is known for its extreme hardness, which contributes to the durability and wear resistance of coatings.

- Excellent Thermal Conductivity: ZrC is highly conductive, making it suitable for thermal management applications.

- High Melting Point: ZrC’s melting point of approximately 3,540°C ensures that it performs well in high-temperature environments.

- Chemical Stability: ZrC films are resistant to oxidation and chemical corrosion, extending the lifespan of coated surfaces.

-

- Excellent Corrosion Resistance: ZrCo particles exhibit outstanding resistance to oxidation and chemical attack, making them ideal for harsh environments.

- High Strength and Hardness: The combination of zirconium and cobalt results in a material with exceptional strength and hardness.

- Thermal Stability: Retains its mechanical properties even at high temperatures.

- Enhanced Wear Resistance: Performs well in applications where abrasion and friction are concerns.

- Customizable Composition and Size: Tailored to meet specific industrial requirements with options in different particle sizes and Zr-Co ratios.

-

- High Strength: ZrCu particles exhibit exceptional mechanical properties suitable for structural and functional components.

- Excellent Corrosion Resistance: Resistant to oxidation and harsh chemical environments.

- Superior Thermal and Electrical Conductivity: Ideal for applications requiring efficient heat and electrical transfer.

- Wear Resistance: Provides durability in high-friction and abrasive environments.

- Customizable Options: Tailored compositions and particle sizes to suit specific industrial needs.