Showing 13–24 of 252 results

-

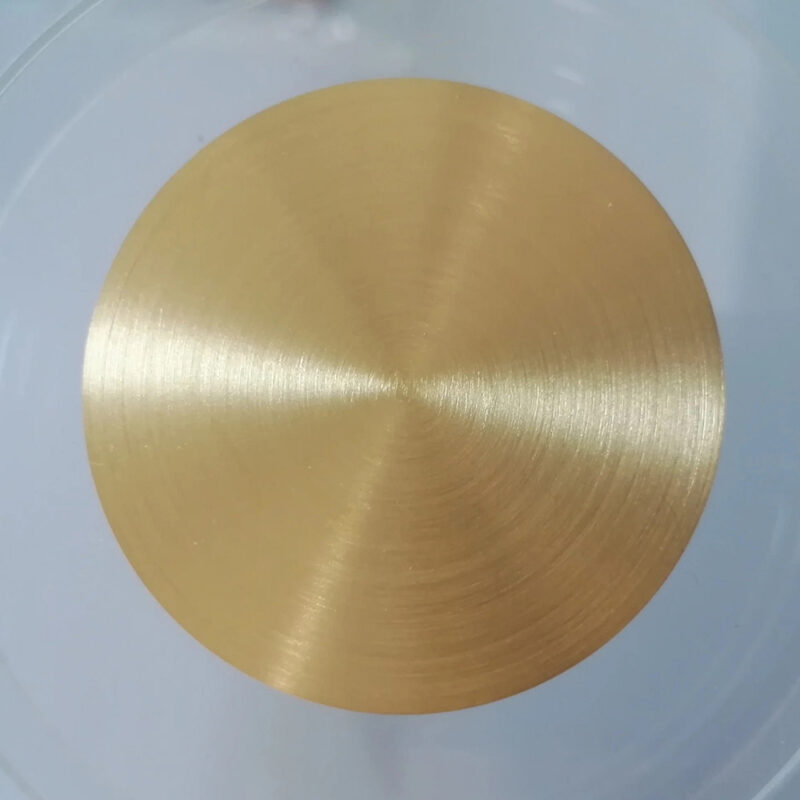

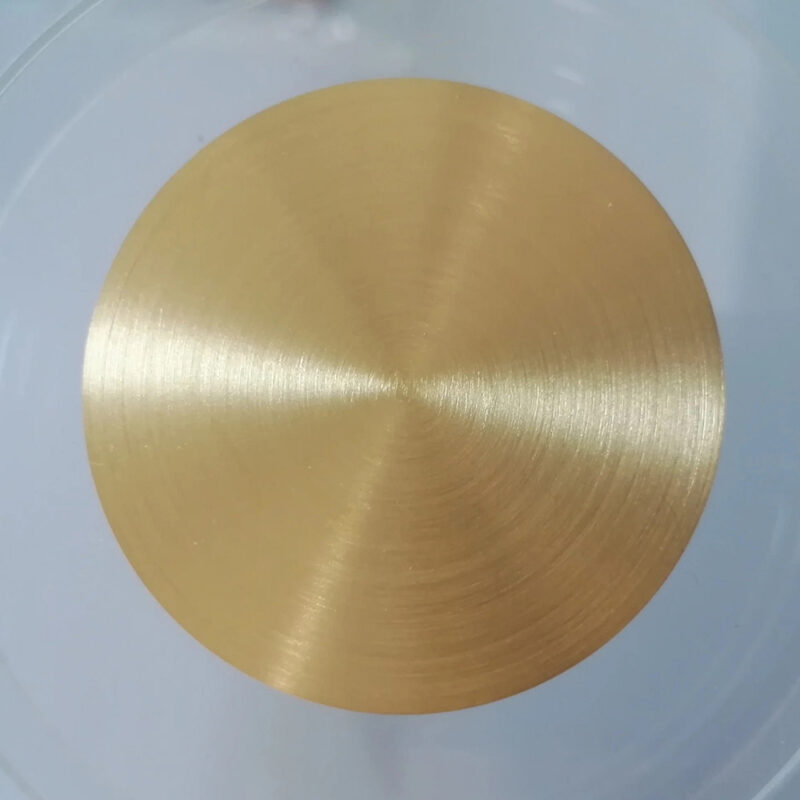

Gold (Au) sputtering target is a very important material of semiconductor, it’s used for depositing gold thin film on the surface of semiconductor chips, to form ohmic contact film, electrode or other films, it can form various metallic films system. Most of gold oxide film system can be used for manufacturing LED, microwave communication device, widely applied in spaceflight, aviation, semiconductor chips and Solar Cells.

-

- High Optical Transparency: AZO offers excellent transparency in the visible spectrum, making it ideal for applications requiring clear conductive films.

- Good Electrical Conductivity: Despite its transparency, AZO provides high electrical conductivity, which is critical in photovoltaic cells and touchscreens.

- Environmentally Friendly: Unlike ITO, AZO does not rely on scarce or expensive elements like indium, making it a more sustainable and cost-effective choice.

- Thermal and Chemical Stability: AZO films maintain stability under various temperature and environmental conditions, making them suitable for outdoor and industrial applications.

- Low Reflectivity: AZO films are known for their low reflectance, which is beneficial in display technologies to reduce glare and improve visibility.

-

Boron (B) sputtering targets are high-purity materials used in physical vapor deposition (PVD) processes, particularly sputtering, to deposit thin films of boron onto various substrates. These targets are widely used in industries such as electronics, optics, and materials science due to boron’s unique properties.

-

- Exceptional Hardness: High resistance to wear and abrasion.

- Chemical Stability: Resistant to acids and alkalis, ensuring longevity in extreme environments.

- Lightweight: Facilitates applications where low weight is critical.

- High Purity: Delivers superior film quality and consistency.

-

Barium (Ba) sputtering targets are high-purity materials used in physical vapor deposition (PVD) processes, particularly sputtering, to create thin films on various substrates. Barium targets are typically used in the production of optical coatings, semiconductor devices, and other advanced materials due to their unique properties.

-

- High Dielectric Constant: BaTiO₃ is known for its exceptionally high dielectric constant, making it ideal for capacitors and electro-optic applications.

- Ferroelectric and Piezoelectric Properties: The material exhibits both ferroelectric and piezoelectric behaviors, making it suitable for memory devices, sensors, and actuators.

- Excellent Thermal Stability: BaTiO₃ maintains good thermal stability, ensuring reliable performance in high-temperature environments.

- High Purity and Low Defects: BaTiO₃ sputtering targets are available in high-purity grades (up to 99.999%), ensuring low defect densities in the deposited thin films, which is crucial for advanced electronic applications.

- Custom Composition: Barium Titanate can be tailored with dopants to modify its electrical and thermal properties, optimizing performance for specific applications.

-

Bismuth (Bi) is a unique metal known for its low toxicity, high density, and distinct electronic properties, making it valuable in specific electronic, optical, and magnetic applications. Bismuth (Bi) sputtering targets are essential for industries requiring specialized thin films with unique electronic, optical, and magnetic properties, particularly in advanced electronics, superconductors, and optical devices.

-

- Layered Structure: Enables the exfoliation of thin films for various nanodevice applications.

- High Carrier Mobility: Supports rapid electron and hole movement for faster electronic response.

- Tunable Bandgap: Adjustable for different applications, optimizing its use in various electronic and optical devices.

- Good Thermal Stability: Suitable for high-temperature applications, enhancing long-term reliability.

-

- High Conductivity: Bi₂S₃ films exhibit good electrical conductivity, making them ideal for use in electronic applications.

- Thermoelectric Efficiency: Known for its high thermoelectric performance, making it a key material in thermoelectric energy conversion devices.

- Optical Transparency: The material has desirable optical transparency in the visible spectrum, which is advantageous for optoelectronic applications.

- Chemical Stability: Bismuth Sulfide is stable under a wide range of chemical conditions, which ensures longevity and reliability in demanding environments.

- High Purity: Bi₂S₃ sputtering targets are available in high purity, ensuring the production of high-quality thin films with minimal contamination.

-

$550.00 – $920.00

- Topological Insulator Properties: Bi₂Se₃ is known for its topological insulator characteristics, where it supports surface conduction while acting as an insulator in its bulk, opening pathways for advanced quantum applications.

- Thermoelectric Efficiency: Bi₂Se₃ exhibits excellent thermoelectric performance with a high Seebeck coefficient, making it a critical material for thermoelectric energy conversion.

- Low Thermal Conductivity: Its low thermal conductivity helps in maximizing the thermoelectric efficiency in power generation and cooling applications.

- High IR Sensitivity: Bi₂Se₃’s sensitivity to infrared radiation makes it ideal for IR sensors and other optoelectronic devices.

-

- Multiferroic Properties: BiFeO₃ demonstrates both ferroelectric and antiferromagnetic properties, making it ideal for multifunctional devices.

- Room Temperature Functionality: One of the few multiferroic materials that operates effectively at room temperature, allowing for broader application in consumer electronics and industrial devices.

- Photovoltaic Effects: BiFeO₃ can be used to create thin films that convert light into electricity, opening avenues for energy harvesting and improving photovoltaic technologies.

- Customizable: The size, shape, and purity of BiFeO₃ sputtering targets can be tailored to meet specific requirements for various deposition techniques.

-

- Excellent Thermoelectric Performance: BiSbTe is known for its high thermoelectric efficiency, which makes it ideal for thermoelectric cooling and energy conversion applications.

- Wide Temperature Range: BiSbTe thin films perform effectively across a broad range of temperatures, particularly between 200 K and 400 K, making them suitable for various environmental conditions.

- Customizable Compositions: The composition of BiSbTe sputtering targets can be adjusted by varying the ratio of bismuth, antimony, and tellurium to meet specific thermoelectric performance requirements.

- High Purity: BiSbTe sputtering targets are available in high-purity grades to ensure the highest quality thin films for critical applications in energy harvesting and temperature regulation.

- Stable & Durable: Bismuth Antimony Telluride thin films exhibit excellent stability, long-term durability, and resistance to degradation under prolonged thermal cycling.