Showing 337–348 of 678 results

-

- High Purity: Consistently high purity, making it ideal for applications requiring excellent material integrity.

- Thermal Insulation: Excellent thermal conductivity, making it an ideal material for refractory products and high-temperature insulation.

- Electrical Insulation: Acts as an effective electrical insulator in components like electrical cables and ceramics.

- Chemical Stability: Resistant to chemical attack, making it suitable for harsh environments.

- Environmental Safety: Non-toxic and safe for various industrial applications.

- Versatility: Available in various particle sizes and customizable formulations to meet specific application needs.

-

- High Purity: Guarantees consistent and reliable thin-film quality.

- Thermal Stability: Performs exceptionally under high-temperature conditions.

- Excellent Dielectric Properties: Ideal for insulating layers in electronic devices.

- Wide Optical Transparency: Operates effectively across UV, visible, and IR spectra.

- Customizable Options: Available in various shapes, sizes, and specifications.

-

- High Purity: Manganese pellets are available in high purity levels, typically ≥ 99.5%, ensuring precise and consistent film quality.

- Uniform Shape: Pellets are designed for smooth and uniform evaporation, providing consistent thin film deposition.

- Good Hardness and Strength: Manganese films contribute to increased surface hardness and wear resistance.

- Magnetic Properties: Useful for applications requiring magnetic thin films or for enhancing magnetic properties in alloys.

-

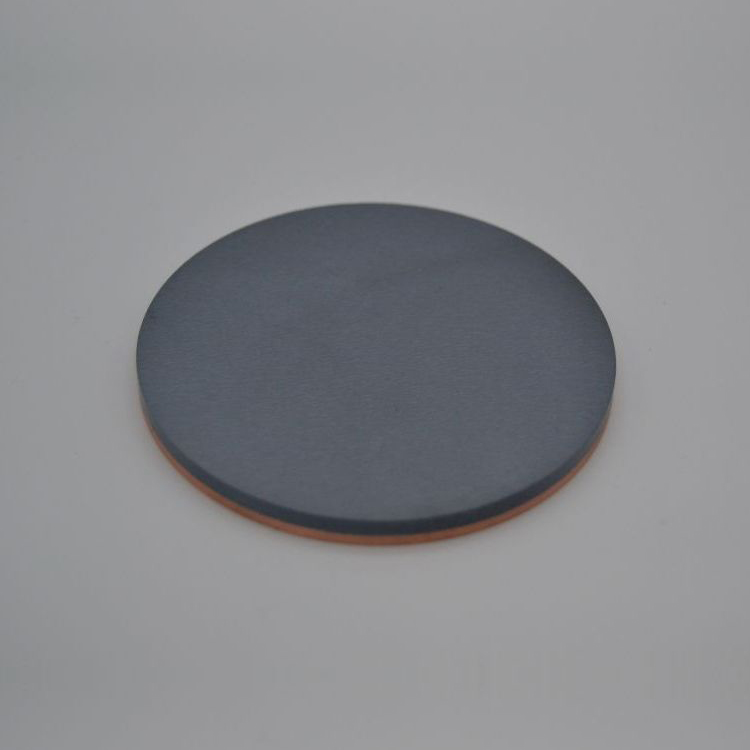

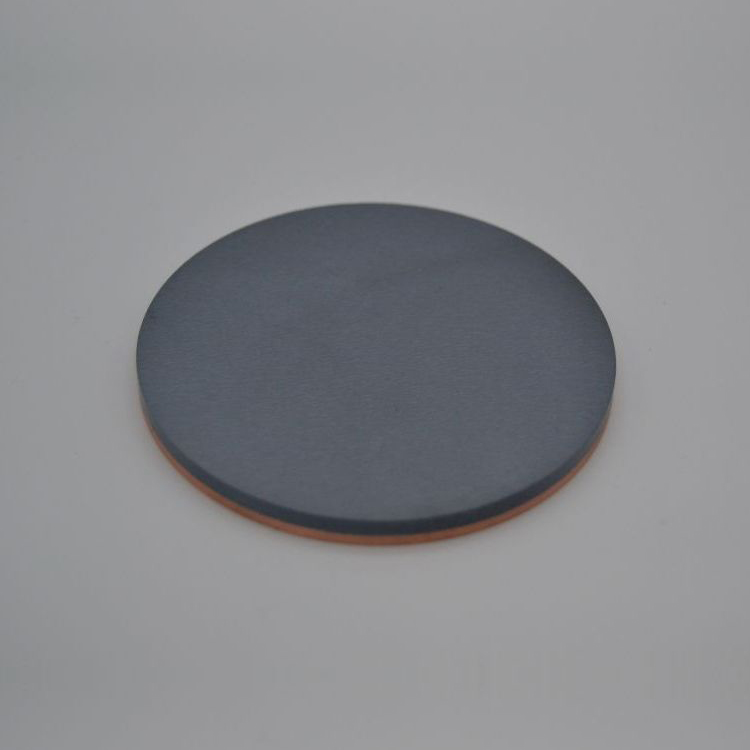

Manganese (Mn) sputtering targets are essential for industries that rely on magnetic properties, wear resistance, and corrosion resistance, making them indispensable in electronics, magnetic storage, metallurgy, and catalytic applications.

-

- High Purity: Ensures consistent performance in industrial applications requiring low impurity levels.

- Thermal Stability: Excellent stability under high-temperature conditions, suitable for demanding applications.

- Catalytic Properties: Effective as a catalyst or catalyst precursor in chemical reactions.

- Versatile Applications: Suitable for ceramics, metallurgy, batteries, and chemical processes.

- Customizable Particle Sizes: Available in various particle size distributions to meet specific processing needs.

- Environmentally Friendly: Supports eco-friendly processes in industries like green energy and pollution control.

-

$145.00 – $275.00

- Excellent Oxidizing Properties: MnO2 is known for its strong oxidizing capabilities, which are beneficial in catalysis and energy applications.

- Good Electrical Conductivity: It offers good conductivity in thin-film applications, making it suitable for use in electronic and energy-related devices.

- Versatile Deposition: MnO2 thin films can be used in a wide range of applications, from optics to electronics.

- Chemical Stability: Manganese dioxide is chemically stable, ensuring long-lasting performance in harsh environments.

- High Melting Point: Suitable for high-temperature evaporation processes.

-

- High Purity: Ensures reliability in applications requiring minimal impurities.

- Exceptional Oxidizing Properties: Effective in redox reactions and chemical processes.

- Thermal and Chemical Stability: Performs well under challenging environmental and industrial conditions.

- Versatile Applications: Suitable for use in batteries, ceramics, pigments, and catalysis.

- Customizable Specifications: Available in various grades and particle sizes to suit diverse needs.

- Environmentally Responsible: Supports sustainable and green industrial processes.

-

- High Purity: Available in high-purity grades, ensuring clean and efficient thin-film deposition with minimal contamination.

- Good Electrochemical Properties: MnO₂ thin films are known for their excellent electrochemical behavior, making them ideal for energy storage applications.

- Thermal Stability: MnO₂ exhibits stability at high temperatures, making it suitable for thin-film processes that require heat resistance.

- Wide Range of Applications: The material is versatile, with applications ranging from energy storage and catalysis to optical coatings and sensors.

-

- Semiconducting Properties: MnTe exhibits semiconductor behavior, making it suitable for a variety of electronic and optoelectronic applications.

- Magnetic Properties: With ferromagnetic behavior, MnTe is essential for applications in spintronics and magnetic sensors.

- Thermoelectric Efficiency: The material has promising thermoelectric properties, offering potential in energy harvesting and cooling applications.

- High Purity: MnTe sputtering targets are available in high-purity grades, ensuring the production of clean, high-performance thin films.

- Chemical Stability: MnTe thin films offer chemical stability in various environments, which is critical for long-lasting and reliable device performance.

-

$1.00

- High Melting Point: With a melting point of 2,623°C, molybdenum crucibles are ideal for ultra-high-temperature environments.

- Thermal Stability: Maintains strength and stability at elevated temperatures, ensuring consistent performance.

- Corrosion Resistance: Excellent resistance to chemical corrosion, particularly in reducing atmospheres and molten metals.

- Mechanical Strength: High tensile strength and resistance to deformation, even under thermal stress.

- High Thermal Conductivity: Efficient heat distribution, essential for uniform thermal processes.

- Low Thermal Expansion: Minimal dimensional changes under thermal cycling reduce the risk of cracking or warping.

-

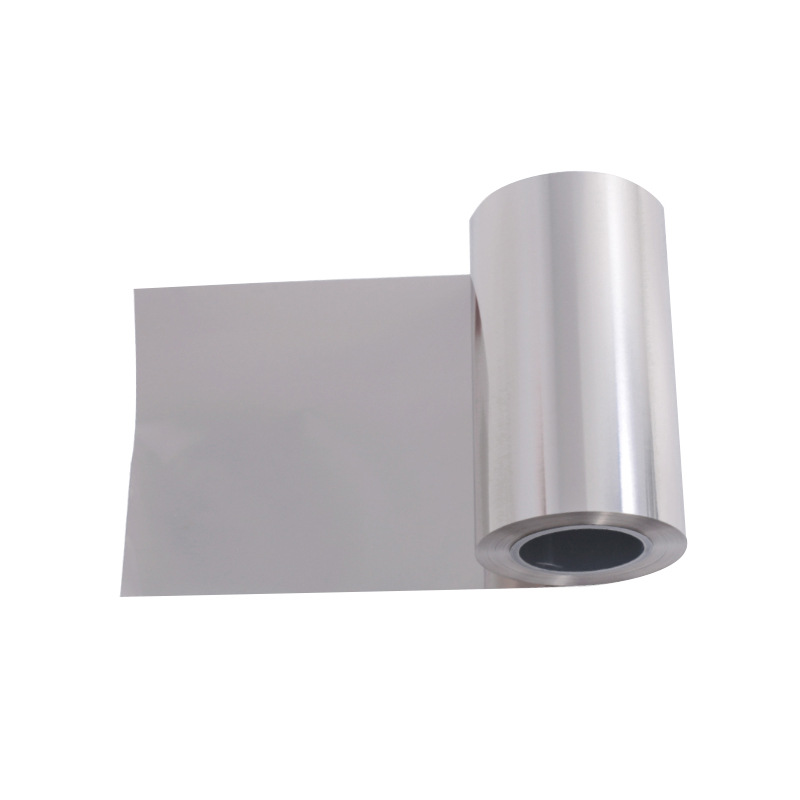

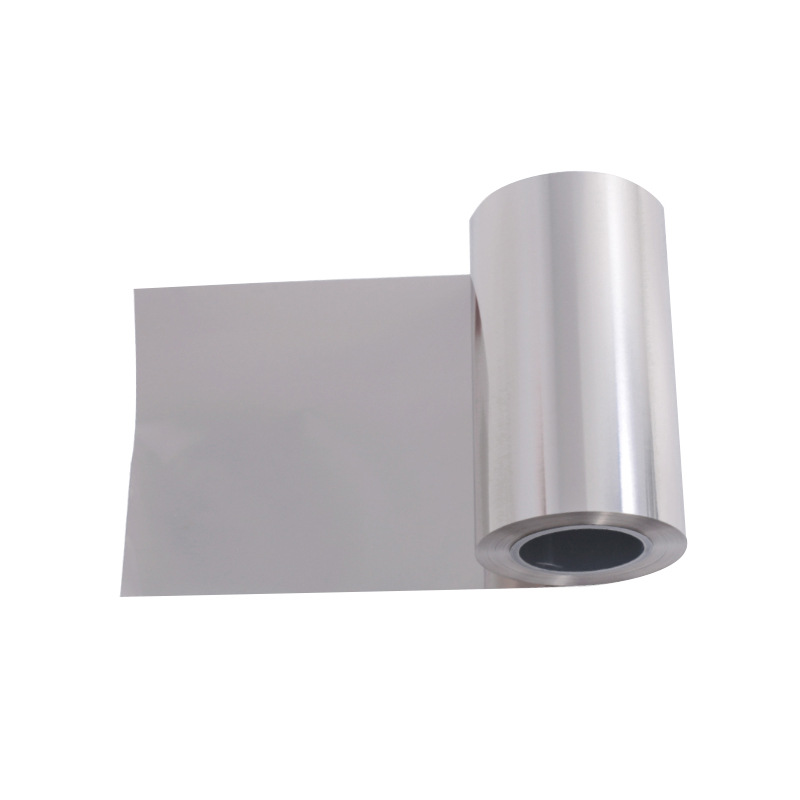

- High Melting Point: With a melting point of 2623°C, molybdenum foil can withstand extreme temperatures.

- Thermal and Electrical Conductivity: Molybdenum exhibits excellent thermal and electrical conductivity, essential for heat dissipation and electrical components.

- High Purity: Available in ultra-high purity grades, ensuring consistent performance in sensitive applications.

- Corrosion Resistance: Molybdenum is highly resistant to oxidation and corrosion, even in extreme environments.

- Strength and Stability: Molybdenum foil maintains mechanical strength and dimensional stability at high temperatures.

- Malleability and Workability: Despite its robustness, molybdenum foil is malleable and can be fabricated into complex shapes.

-

- High Melting Point: Molybdenum has a melting point of 2,623°C, allowing it to withstand extreme temperatures, making it ideal for high-temperature applications.

- Excellent Conductivity: Molybdenum’s electrical and thermal conductivity make it suitable for use in electronics and other heat-sensitive applications.

- Corrosion and Oxidation Resistance: Molybdenum films are highly resistant to corrosion and oxidation, ensuring long-lasting performance in harsh environments.

- Strong Mechanical Properties: Mo provides high tensile strength and stability, making it durable for thin films.

- Adhesion and Uniformity: Molybdenum forms well-adhering and uniform thin films that are highly reflective and durable.