Showing 385–396 of 678 results

-

- Superconducting Properties: Exhibits excellent superconductivity at critical temperatures.

- High Hardness: Exceptional wear resistance and durability for coatings.

- Thermal Stability: Maintains stability under high-temperature conditions.

- Chemical Resistance: Inert to many corrosive environments, ensuring longevity.

- Customizable Particle Size: Tailored for specific applications in research and industry.

-

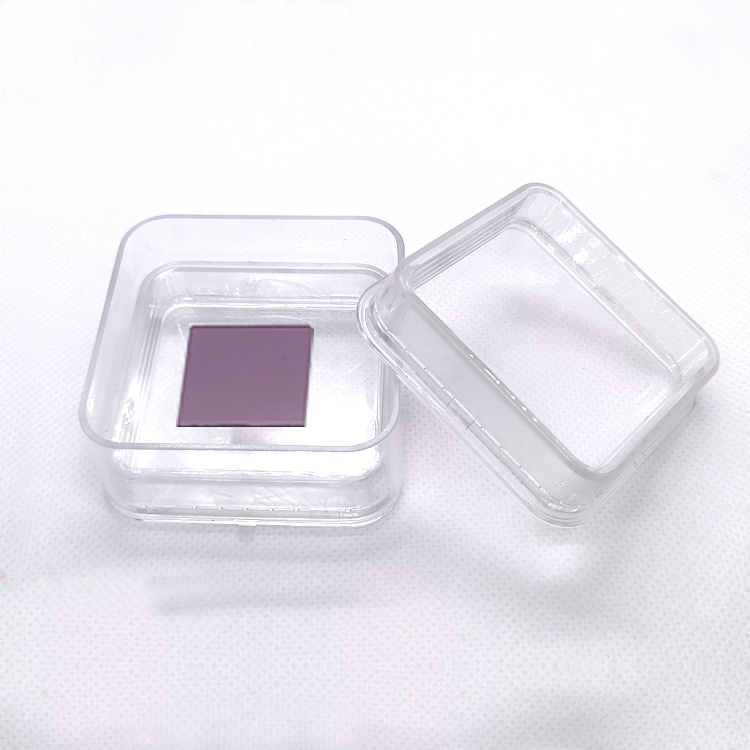

- High Purity: NbN sputtering targets are manufactured with purity levels of up to 99.999%, ensuring excellent film consistency and performance in various deposition applications.

- Electrical Conductivity: Known for its high electrical conductivity, NbN is used in applications requiring efficient electron flow and low resistance.

- Thermal Stability: Niobium nitride exhibits excellent thermal stability, maintaining performance even at elevated temperatures, making it suitable for high-temperature applications.

- Corrosion Resistance: NbN films exhibit outstanding resistance to oxidation and chemical wear, making them ideal for applications in harsh environments.

- Uniformity in Coating: NbN sputtering targets provide excellent film uniformity and density, ensuring reliable coating processes with minimal defects.

- Hardness: The resulting NbN films are known for their exceptional hardness, making them suitable for tough, abrasive conditions.

-

- High Purity: ≥99.5% purity to ensure high-quality thin-film deposition.

- Unique Layered Structure: Facilitates superior electronic and optical properties for advanced applications.

- Superconducting Properties: Ideal for applications in superconducting electronics and quantum computing research.

- High Stability: Reliable performance under sputtering conditions with excellent chemical stability.

- Customizable: Tailored sizes and shapes for different deposition setups.

-

- High Thermal Stability: Performs reliably in extreme temperatures.

- Oxidation Resistance: Ideal for protective coatings in harsh environments.

- Superior Mechanical Strength: Enhances the durability of deposited films.

- High Purity Standards: Ensures film quality and minimal contamination.

- Custom Solutions Available: Adaptable to meet specific industrial or research requirements.

-

- High Dielectric Constant: NbTiO₃ has a high dielectric constant, making it ideal for capacitors and other electronic components requiring high energy density.

- Ferroelectric Properties: The ferroelectric nature of NbTiO₃ enables its use in memory devices and sensors that need stable, reliable performance under varying conditions.

- Optical Transparency: NbTiO₃ thin films provide excellent optical transparency, ensuring their application in optoelectronic devices and displays.

- Chemical and Thermal Stability: NbTiO₃ films are highly stable in both chemical and thermal environments, ensuring long-lasting performance in demanding applications.

-

- High Strength: The alloy provides exceptional mechanical strength, making it suitable for demanding applications.

- Temperature Resistance: Offers good resistance to high temperatures, maintaining performance under thermal stress.

- Corrosion Resistance: Resistant to oxidation and corrosion, enhancing the lifespan of components in harsh environments.

-

- Magnetic Properties: Neodymium is known for its exceptional magnetic strength, making it ideal for use in permanent magnets, motors, and generators.

- Optical Properties: Neodymium-doped materials exhibit excellent optical properties, particularly in lasers and glass coloring.

- Alloying: When alloyed with other metals, neodymium improves the strength, ductility, and resistance to high temperatures, making it suitable for specialized applications.

- Catalysis: Neodymium compounds act as effective catalysts in the petrochemical industry, helping refine crude oil into gasoline and other products.

- High Thermal Resistance: Neodymium powder can withstand high temperatures, making it suitable for high-temperature environments and applications such as in electric motors and energy storage.

-

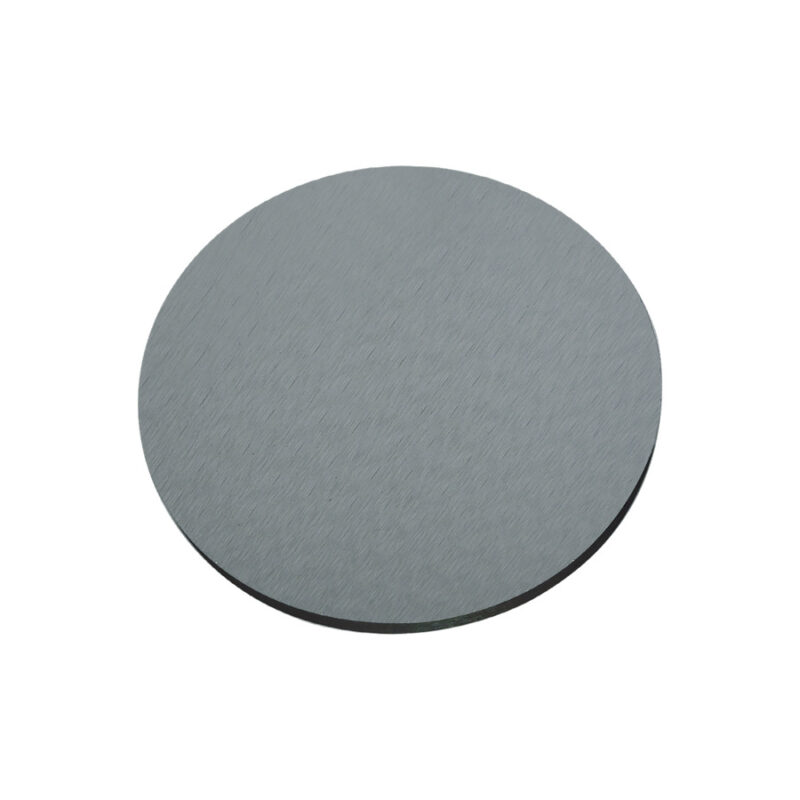

- Purity: High purity (99.9% or higher) is critical to ensure the quality and performance of the deposited film.

- Shape and Size: These targets are available in different shapes, such as discs, plates, and cylinders, with customizable dimensions to fit specific sputtering systems.

- Density and Grain Size: Neodymium targets are manufactured with high density and controlled grain size to improve sputtering efficiency and consistency.

- Magnetic Properties: Neodymium is ferromagnetic, making it ideal for applications requiring magnetic properties.

-

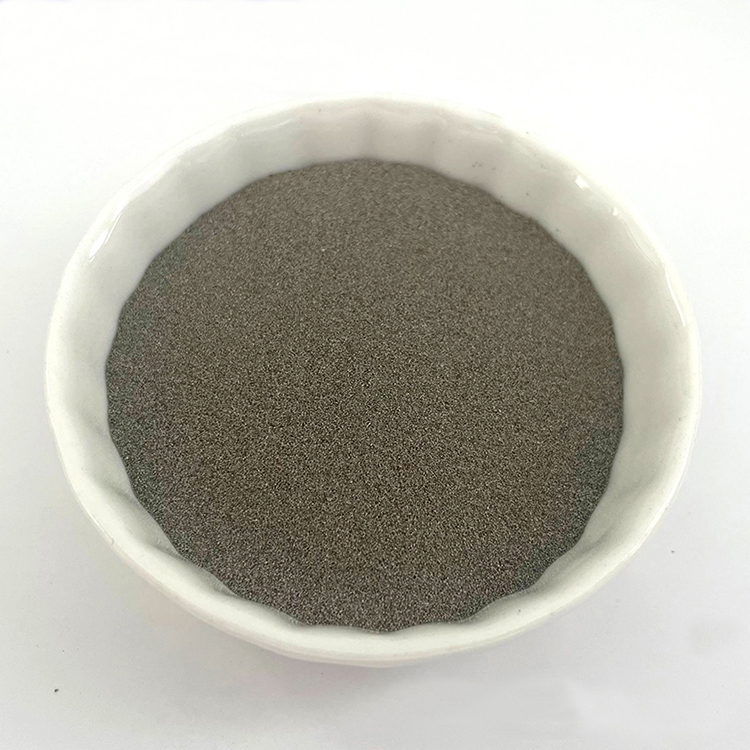

- High purity levels (≥99.9% or ≥99.99%).

- Stable physical and chemical properties.

- Uniform particle size suitable for industrial and laboratory use.

- Customizable specifications available upon request.

-

- High Purity: Purity levels of ≥99.5% for reliable performance in sensitive applications.

- Magnetic Properties: Essential in manufacturing high-performance neodymium magnets.

- Optical Clarity: Enhances coloration and UV resistance in glass and ceramics.

- Thermal Stability: Maintains performance in high-temperature environments.

- Customizable Particle Size: Available in nano (<100 nm) and micro (1–50 µm) grades or customized.

-

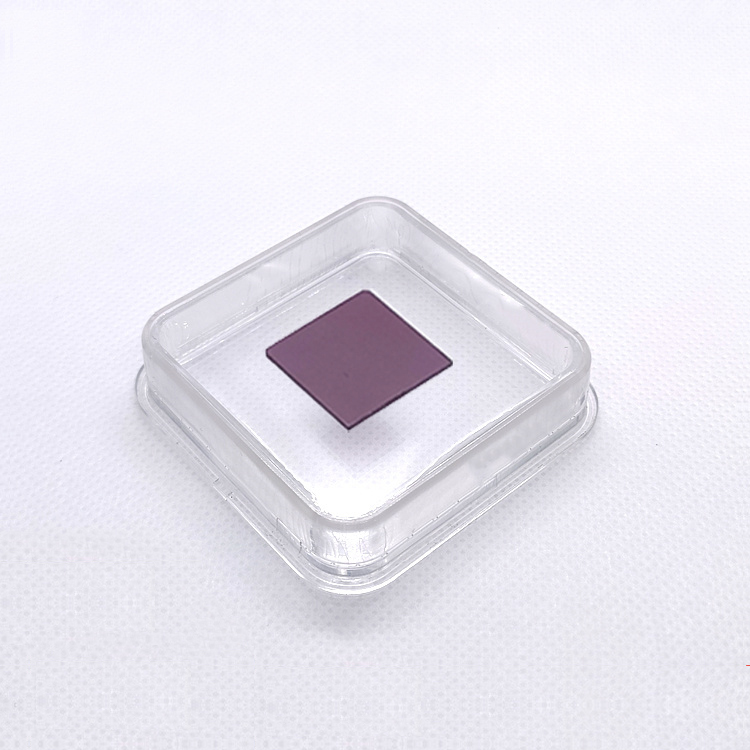

- Magnetic Properties: Neodymium oxide exhibits magnetic behavior, making it valuable in magneto-optic devices and sensors where control of magnetic fields is required.

- Optical Transparency: Nd₂O₃ thin films offer optical transparency in the infrared range, making them ideal for optical coatings and filters in laser and photonic devices.

- High Refractive Index: The high refractive index of Nd₂O₃ allows for efficient control of light in optical applications, especially in the IR spectrum.

- Chemical Stability: Nd₂O₃ is highly stable in various chemical environments, ensuring durability and performance in industrial and research applications.

-

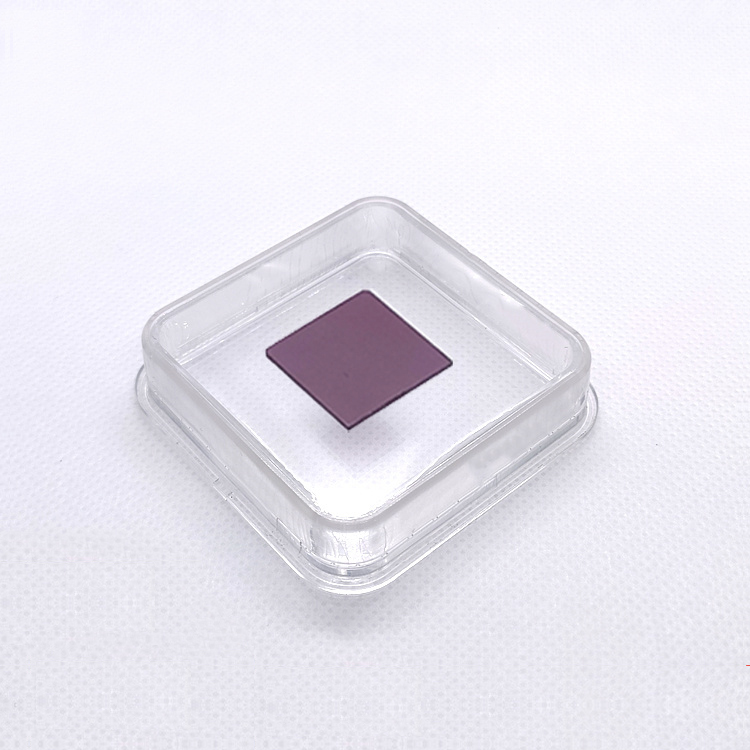

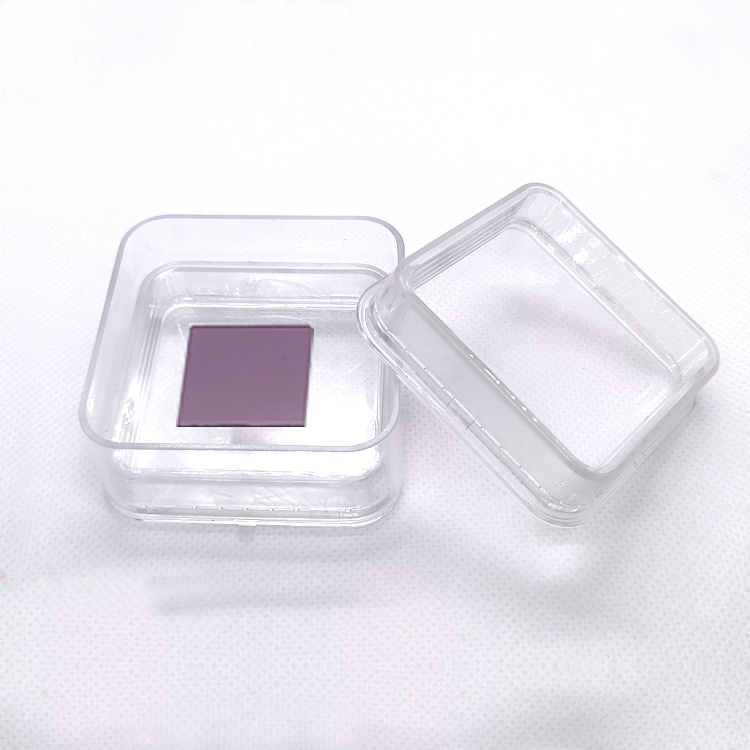

- Excellent Thermal Stability: Maintains crystal integrity at high operating temperatures.

- Good Chemical Resistance: Resists degradation in acidic and basic environments.

- Low Lattice Mismatch: Ideal for the epitaxial growth of complex oxides and superconducting films.

- High Mechanical Strength: Reduces risk of cracking during processing and device operation.

- Superior Surface Quality: Supports high-quality thin film deposition.

- Perovskite-like Structure: Compatible with a broad range of oxide thin films.

- Stable Optical Properties: Suitable for use in optical communication and laser components.