Showing 397–408 of 678 results

-

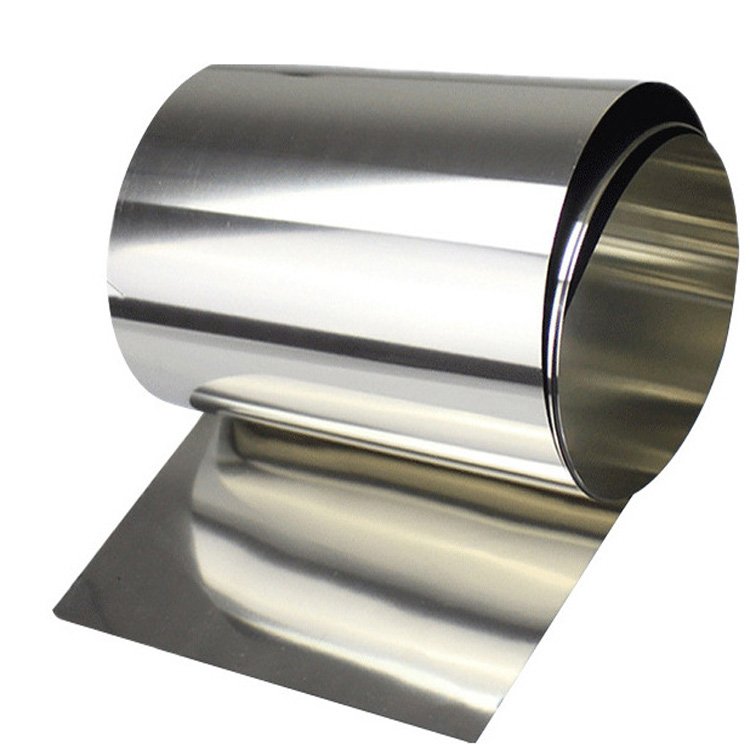

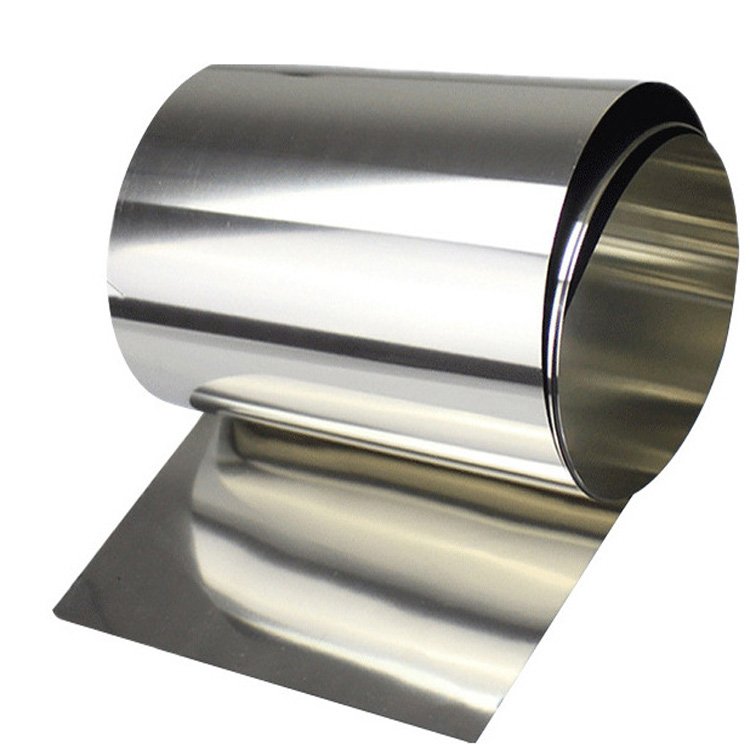

- Corrosion Resistance: Nickel foil is highly resistant to corrosion, especially in harsh environments, making it suitable for applications in corrosive conditions like chemical processing and marine industries.

- High Thermal Stability: Nickel foil maintains its performance at high temperatures, ensuring stable functionality in high-heat applications such as furnaces and heat exchangers.

- Excellent Electrical Conductivity: Known for its good electrical conductivity, nickel foil is used in the electronics industry for components like batteries, capacitors, and electrical connections.

- Malleability and Flexibility: Nickel foil is malleable and can be easily shaped into thin sheets, which is beneficial for precision applications that require flexibility.

- Magnetic Properties: Nickel exhibits ferromagnetic properties, making it ideal for use in magnetic shielding applications and other electromagnetic devices.

- Durability and Strength: Nickel foil is tough and resistant to wear and tear, ensuring long-lasting performance in demanding applications.

-

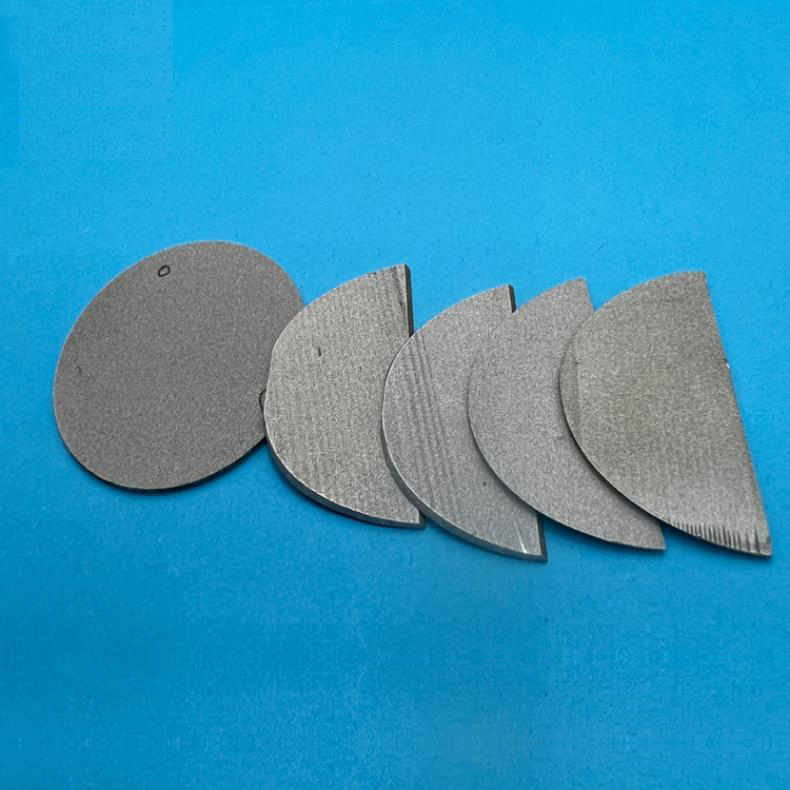

- High Purity: Nickel pellets are available with purity levels of ≥ 99.9%, ensuring superior quality films.

- Uniform Shape: Designed for smooth and consistent evaporation, providing uniform film thickness.

- High Conductivity: Excellent thermal and electrical conductivity make it ideal for electronic and thermal applications.

- Corrosion Resistance: Nickel’s natural resistance to oxidation ensures long-lasting coatings in corrosive environments.

- Magnetic Properties: Suitable for applications that require magnetic thin films.

-

- High Purity: Ensures superior performance in critical applications.

- Corrosion Resistance: Exceptional resistance to oxidation and harsh environments.

- Thermal Stability: Performs reliably under high-temperature conditions.

- Excellent Conductivity: High electrical and thermal conductivity for electronic and energy applications.

- Customizable Particle Sizes: From nano to micrometer scales for specific industrial needs.

- Versatile Applications: Suitable for batteries, coatings, catalysts, and additive manufacturing.

-

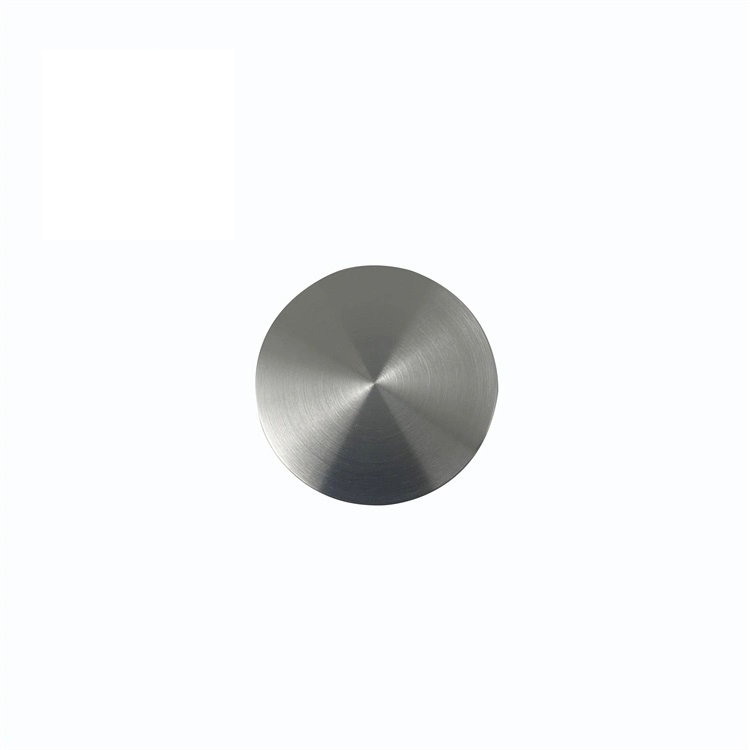

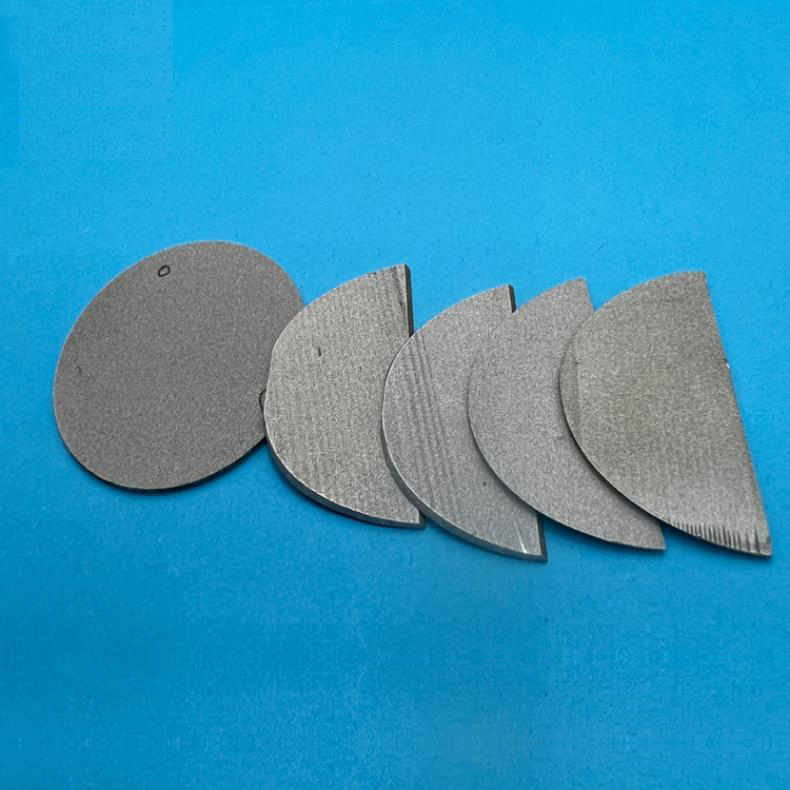

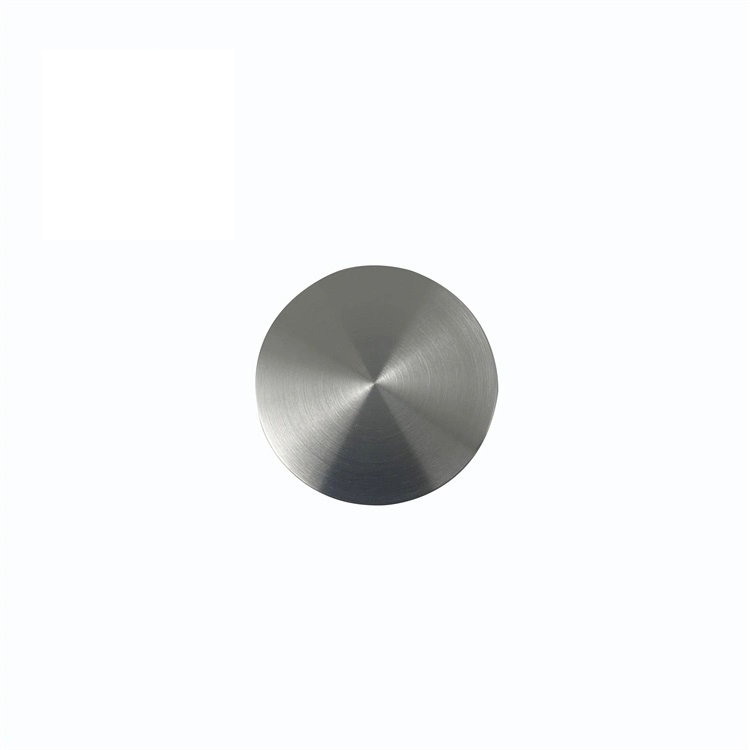

- Thickness: The thickness of the nickel coating can be precisely controlled during the sputtering process, allowing for customized solutions to meet specific application needs.

- Alloys: Nickel sputtering targets can be produced as pure nickel or in alloyed forms, such as nickel-cobalt (Ni-Co) or nickel-chromium (Ni-Cr), depending on the desired properties of the thin film.

- Backing Plates: Nickel targets can be bonded to backing plates made from materials like copper or molybdenum to improve thermal conductivity and mechanical stability during the sputtering process.

-

- High Corrosion Resistance: Nickel wire is highly resistant to oxidation and corrosion, especially in harsh environments, such as acidic or alkaline conditions.

- Excellent Electrical Conductivity: Offers stable and reliable electrical conductivity, making it ideal for electrical and electronic applications.

- Thermal Resistance: Can withstand high temperatures without degrading, making it suitable for heat-intensive processes.

- Ductility and Workability: Highly malleable and ductile, allowing it to be drawn into thin wires or shaped for specific applications.

- Magnetic Properties: Nickel exhibits ferromagnetic properties, enabling its use in magnetic and electronic components.

- High Melting Point: Nickel has a melting point of 1455°C, allowing it to maintain performance under extreme conditions.

-

- High Hardness: The alloy provides superior hardness, significantly improving wear resistance.

- Corrosion Resistance: Offers good protection against oxidation and chemical degradation.

- Enhanced Magnetic Properties: Suitable for applications requiring ferromagnetic materials.

-

- High Hardness: Provides superior wear resistance.

- Thermal Stability: Excellent performance in high-temperature environments.

- Electrical Conductivity: Suitable for use in electronic and thermal applications.

- Corrosion Resistance: Durable in harsh chemical environments.

- Versatility: Applicable in coatings, composites, and alloy enhancements.

-

- Excellent Mechanical Strength: Suitable for high-stress applications

- Good Thermal Conductivity: Facilitates high-temperature processing

- Corrosion Resistance: Stable in oxidizing and reducing environments

- High Crystallinity: Supports high-quality epitaxial growth

- Magnetic Properties: Useful for spintronics and magnetic studies

- Surface Stability: Ideal for ultra-high vacuum (UHV) surface science experiments

- Customizable: Wide range of sizes, orientations, and surface finishes

-

- High Electrical Resistivity: NiCr alloy is valued for its stable and reliable electrical resistivity, making it ideal for resistive coatings in electronic devices.

- Oxidation and Corrosion Resistance: Chromium in the alloy provides excellent resistance to oxidation and corrosion, especially at elevated temperatures, ensuring longevity in harsh conditions.

- Thermal Stability: NiCr retains its mechanical and electrical properties under extreme heat, making it suitable for applications involving high temperatures, such as heating elements.

- Customizable Composition: The ratio of nickel and chromium can be adjusted to optimize properties like electrical conductivity or resistance to oxidation, depending on the specific application.

-

- High purity (≥99.9%).

- Outstanding electrical resistivity and thermal stability.

- Exceptional corrosion and oxidation resistance.

- Uniform pellet size for consistent deposition rates.

- Suitable for PVD and CVD thin-film deposition.

-

- High Electrical Resistivity: The NiCrSi alloy has a stable electrical resistivity, making it ideal for thin-film resistor applications and other electronics requiring consistent electrical performance.

- Corrosion and Oxidation Resistance: The combination of nickel and chromium provides excellent resistance to corrosion and oxidation, even at elevated temperatures.

- Thermal Stability: The NiCrSi alloy retains its mechanical and electrical properties at high temperatures, ensuring reliable performance in thermal management systems and high-temperature applications.

- Customizable Composition: The nickel, chromium, and silicon content can be adjusted to fine-tune the properties of the alloy for specific applications, including optimizing resistivity or corrosion resistance.

-

- High Electrical Conductivity: NiCu alloy sputtering targets offer excellent electrical conductivity, making them ideal for thin films in electronic devices where efficient current flow is essential.

- Corrosion Resistance: The combination of nickel and copper provides strong corrosion resistance, allowing the thin films to withstand exposure to chemicals and harsh environments, such as marine and industrial settings.

- Magnetic Properties: NiCu alloys exhibit useful magnetic properties, which can be tailored for specific applications such as sensors, transformers, and other magnetic devices.

- Thermal Stability: NiCu alloy thin films maintain their structural integrity at elevated temperatures, making them suitable for high-temperature applications in aerospace and industrial settings.

- Customizable Composition: The ratio of nickel to copper can be adjusted to optimize the properties of the thin film for specific applications, such as enhancing conductivity or corrosion resistance.