Showing 433–444 of 678 results

-

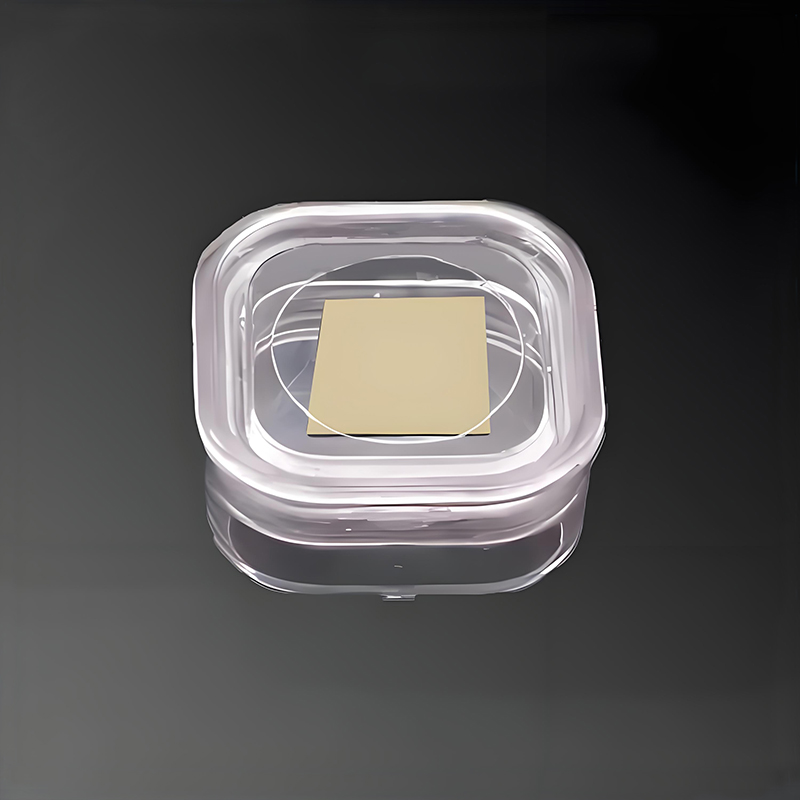

- Ultra-High Piezoelectric Coefficient (d₃₃ > 1500 pC/N): Enables extremely sensitive actuation and sensing.

- High Electromechanical Coupling Coefficient (k₃₃ > 0.9): Ensures efficient energy conversion.

- Large Strain (>0.1%): Suitable for actuators requiring high displacement.

- Low Dielectric Loss: Enhances energy efficiency and system stability.

- Superior Bandwidth and Sensitivity: Critical for medical ultrasound and SONAR transducers.

- Low Acoustic Impedance: Better matching with human tissues for biomedical applications.

- Customizable Crystal Composition (PMN-PT with various PT ratios): Tunable properties based on application requirements.

- Excellent Optical Quality (for thin PMN-PT films): Applicable in electro-optic modulators and photonic devices.

-

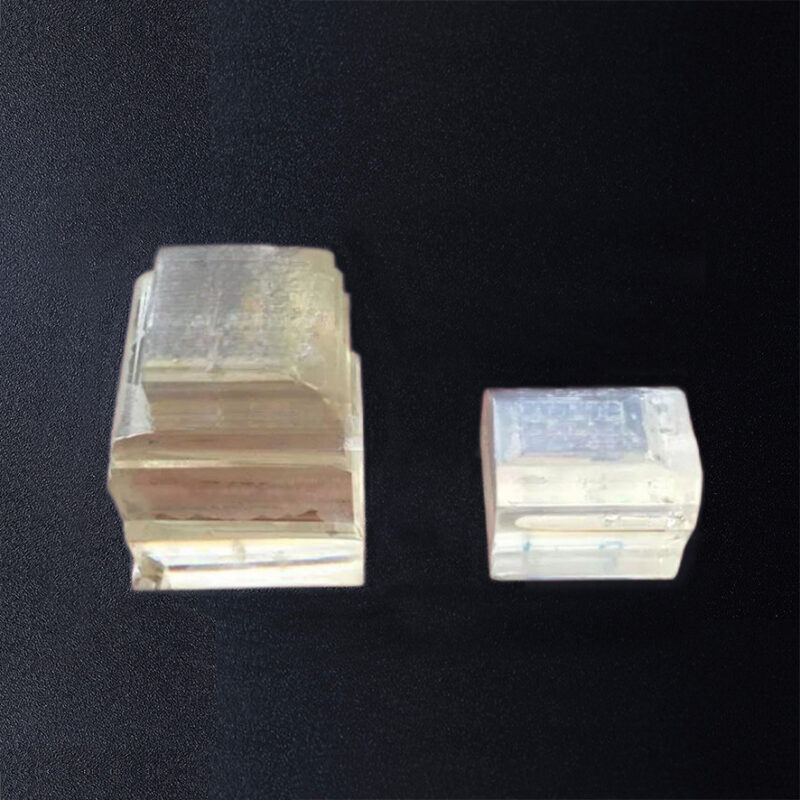

- High Structural Perfection: Ideal lattice matching for growing oxide thin films such as superconductors and ferroelectric films.

- Excellent Dielectric Properties: High dielectric constant makes it suitable for tunable capacitors and microwave applications.

- Low Optical Absorption: Transparent in the visible to near-infrared spectrum, useful for optoelectronic devices.

- High Mechanical and Chemical Stability: Ensures robustness in diverse environments.

- Ferroelectric and Quantum Paraelectric Behavior: Suitable for research in quantum phase transitions and low-temperature physics.

- Epitaxial Growth Substrate: Preferred for epitaxy of functional oxide materials such as high-temperature superconductors, ferroelectric, and multiferroic materials.

-

- High Purity: Praseodymium pellets are typically available at a purity level of 99.9% or higher, ensuring the quality of deposited thin films.

- Excellent Magnetic and Optical Properties: Praseodymium has favorable magnetic and optical properties, making it ideal for applications in optical devices and electronics.

- Thermal Stability: Praseodymium thin films demonstrate good stability under high temperatures, suitable for use in high-performance environments.

- Versatility in Applications: From optics to electronics, Praseodymium is versatile and can be integrated into a range of advanced technological applications.

-

Praseodymium sputtering targets are essential for creating thin films with specialized magnetic, optical, and electrical properties, making them valuable in advanced technological applications such as permanent magnets, lasers, display technologies, and specialized alloys. Despite its rarity, praseodymium’s unique characteristics offer significant benefits in cutting-edge industrial and scientific applications.

-

- High Purity: Available in high-purity forms (typically ≥ 99.9%), ensuring the quality and consistency of the deposited films in sensitive optical and electronic applications.

- Excellent Optical Properties: Pr6O11 provides reliable performance in optical films, contributing to the modulation of light in various optical components.

- Thermal and Chemical Stability: Its stability at high temperatures makes it a suitable material for thermal evaporation and other vacuum deposition methods.

- Versatile Applications: Pr6O11 pellets are used across multiple industries, including electronics, optics, ceramics, and catalysis.

-

$1.00

- Material Purity: ①Made from high-purity platinum (typically ≥ 99.95%). ②Can be alloyed with rhodium or iridium for enhanced durability.

- Thermal Stability: ①Excellent performance under high temperatures, withstanding up to 1,700°C without deformation. ②High melting point of platinum (1,768°C) ensures reliable operation.

- Corrosion Resistance: Exceptional resistance to acids, alkalis, and other corrosive agents, including aqua regia and oxidizing environments.

- High Thermal Conductivity: Ensures uniform heat distribution for precise laboratory results.

- Mechanical Strength: Resists cracking and deformation under thermal and mechanical stress.

-

- High Purity: Platinum pellets are typically available with purity levels of 99.95% (3N5) or higher, ensuring that the resulting thin films are of the highest quality and free from contamination.

- High Melting Point: With a melting point of 1768°C, platinum is suitable for high-temperature evaporation processes.

- Excellent Corrosion Resistance: Platinum coatings offer superior protection against corrosion and oxidation, making them ideal for use in harsh environments.

- Good Electrical Conductivity: Platinum’s excellent conductivity makes it a popular choice for thin-film electrodes and interconnects in microelectronics and other applications.

- Durability: Platinum coatings are resistant to wear, making them long-lasting and suitable for high-use applications.

-

- Exceptional Catalytic Properties: Platinum is one of the most efficient catalysts, facilitating numerous chemical reactions in the automotive, chemical, and energy industries.

- High Electrical and Thermal Conductivity: Makes platinum ideal for electronic and thermal applications.

- Corrosion and Oxidation Resistance: Platinum resists corrosion and maintains its integrity even in harsh environments.

- High Stability: Performs well at elevated temperatures, making it suitable for extreme conditions.

- Hydrogen Absorption: Platinum is highly effective in processes involving hydrogen storage and purification.

-

- Chemical Resistance: PTFE is highly resistant to a wide range of chemicals, including acids, bases, and solvents, making it ideal for corrosive applications.

- Non-Stick Surface: The material’s low surface energy allows for the production of coatings that resist adhesion, which is beneficial in various applications.

- Electrical Insulation: Excellent dielectric properties make it a great choice for insulating electrical components.

- High Temperature Resistance: PTFE can withstand a broad temperature range, maintaining its performance even at high temperatures.

- Durable Coatings: PTFE sputtering targets produce uniform and durable coatings with low friction and high wear resistance.

-

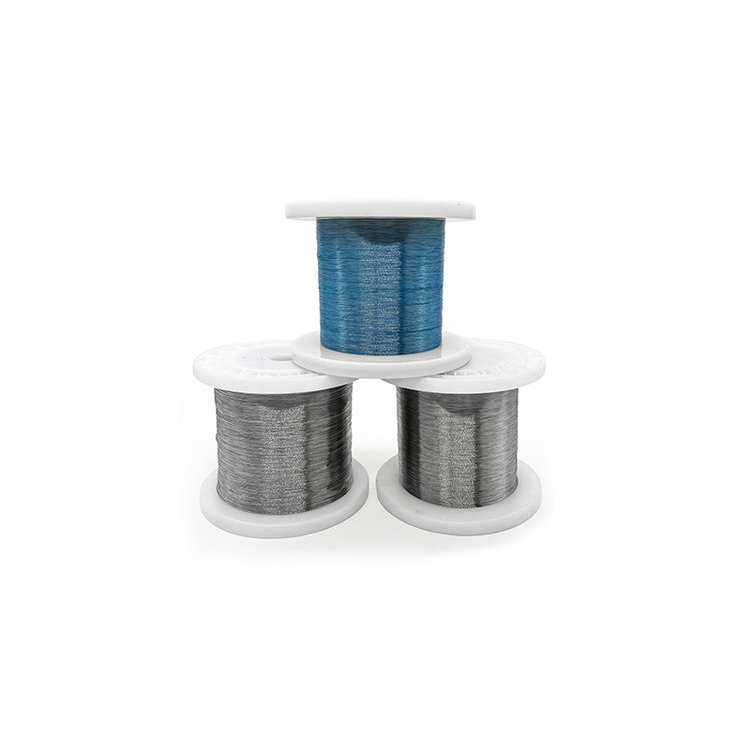

- High Melting Point: The platinum-iridium alloy has a high melting point (1,768°C for platinum and 1,410°C for iridium), making it suitable for use in high-temperature environments without degrading.

- Excellent Corrosion and Oxidation Resistance: Platinum-iridium wires exhibit remarkable resistance to oxidation, corrosion, and chemical degradation. They maintain their integrity in harsh environments, including exposure to acids, high-temperature oxidation, and aggressive chemicals.

- Superior Electrical Conductivity: Platinum-Iridium wires provide excellent electrical conductivity while maintaining stability under high temperatures. This makes them ideal for high-precision electrical applications, such as thermocouples and resistors.

- Thermal Stability: With low thermal expansion and high thermal stability, platinum-iridium wires perform well across a broad temperature range, making them ideal for high-temperature applications like sensors and thermocouples.

- Mechanical Strength: The combination of platinum and iridium provides high mechanical strength and hardness, enabling platinum-iridium wires to withstand heavy-duty use without bending or breaking easily.

- Non-Toxic and Biocompatible: Platinum-iridium alloys are biocompatible and non-toxic, making them suitable for medical devices and applications where material safety is crucial.

- Durability and Longevity: Due to their outstanding resistance to corrosion and wear, platinum-iridium wires can last significantly longer than many other metals, reducing maintenance costs and increasing reliability in critical applications.

-

- High Piezoelectric Coefficient: Enables efficient conversion of mechanical energy to electrical energy and vice versa.

- Stable Dielectric Properties: Ensures reliable performance in high-frequency applications.

- Customizable Compositions: Tailored Zr/Ti ratios to meet specific functional requirements.

- High Purity and Uniformity: Ensures consistent film deposition with minimal defects.

- Versatile Deposition: Compatible with RF and DC magnetron sputtering systems.

-

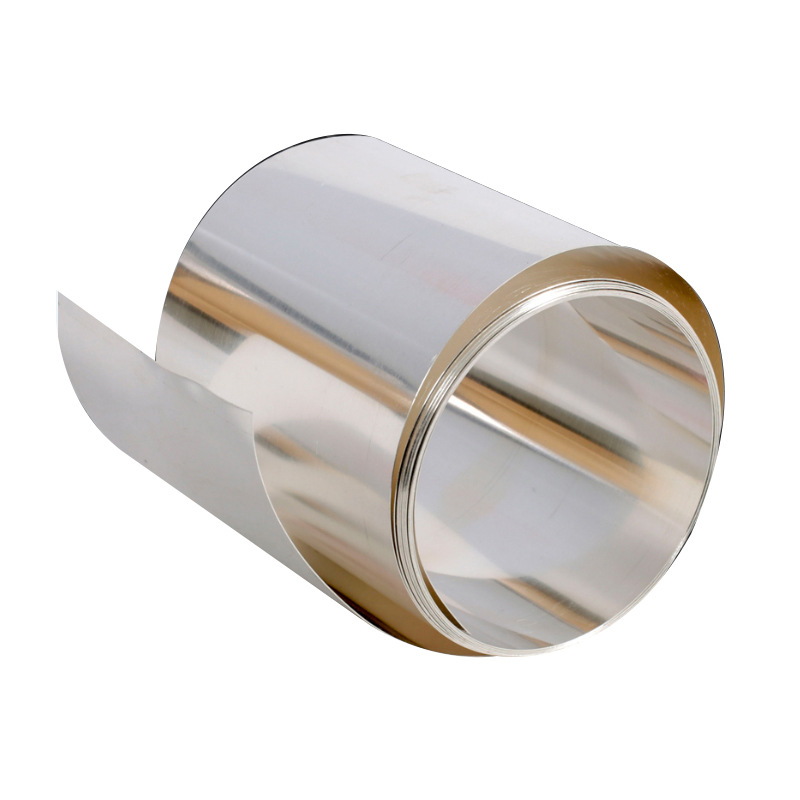

- High Melting Point: Rhenium has an extremely high melting point of 3180°C, making it ideal for use in environments with intense heat.

- Excellent Corrosion and Oxidation Resistance: Rhenium foil shows outstanding resistance to oxidation and corrosion, even at high temperatures.

- High Density and Strength: Known for its superior density and strength, rhenium foil maintains structural integrity under heavy loads and extreme temperatures.

- Thermal and Electrical Conductivity: Rhenium exhibits excellent thermal and electrical conductivity, making it suitable for high-performance applications in electronics.

- Malleability and Ductility: Despite its strength, rhenium foil can be easily processed, providing flexibility in various manufacturing processes.