Showing 553–564 of 678 results

-

- Durability in Extreme Conditions: Titanium wire retains its properties in extreme temperatures and corrosive environments, ensuring reliable performance.

- Lightweight Design: The low density of titanium wire reduces the weight of structures and components, crucial for aerospace and automotive industries.

- Environmentally Friendly: Titanium is non-toxic and fully recyclable, making it a sustainable material choice.

- Customizability: Titanium wire can be manufactured in various diameters, grades, and finishes to meet specific industry requirements.

- Superior Surface Finish: The wire can be polished or coated to enhance its performance and appearance in specialized applications.

-

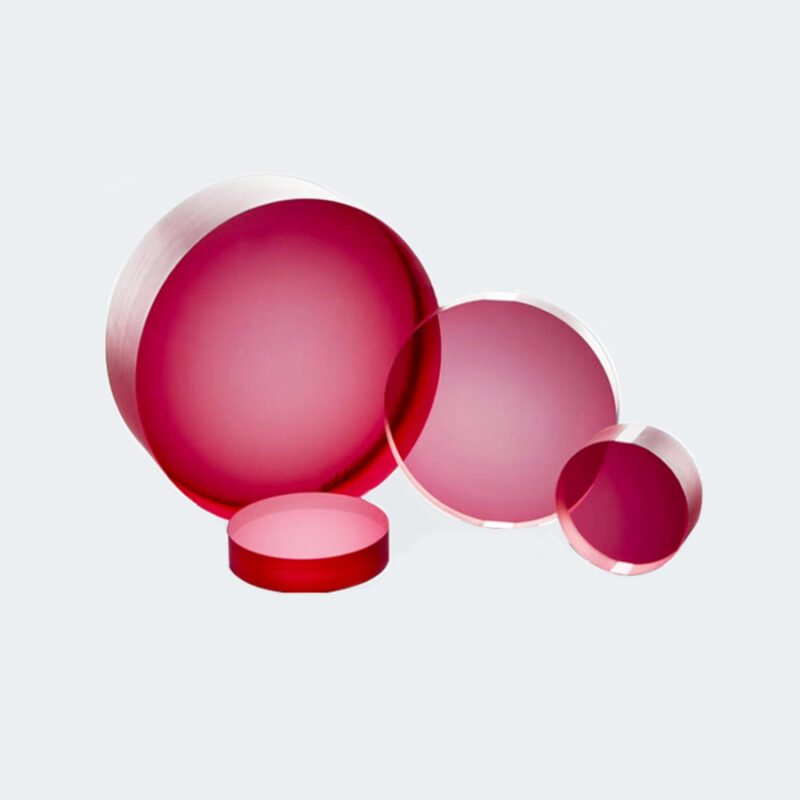

- Broad tunable laser output: 650–1100 nm

- Peak emission wavelength around 800 nm

- Wide absorption band: 400–600 nm (pumpable by 514–532 nm green lasers)

- Extremely broad gain bandwidth – ideal for femtosecond pulses

- High damage threshold and chemical stability

- Excellent thermal conductivity and optical quality

- Supports ultrashort pulse generation (<10 fs)

-

- High purity (≥99.99%).

- Excellent electrical conductivity and stability.

- Unique optical properties, including selective light absorption.

- Uniform pellet size for consistent deposition and performance.

- Customizable sizes and packaging for various applications.

-

- High Purity: Ensures uniform film deposition with minimal contamination.

- Excellent Optical Properties: Provides transparency and reflectivity for optical applications.

- Electrical Conductivity: Suitable for applications requiring conductive thin films.

- Durable and Stable: Resistant to chemical and thermal degradation, ensuring long-lasting performance.

- Versatile Compatibility: Can be used with various sputtering systems and processes.

-

$25.00 – $130.00

- High Refractive Index: Ti₃O₅ has a high refractive index, making it suitable for optical coating applications where control of light reflection and transmission is essential.

- Excellent Thermal Stability: With a high melting point and stability at elevated temperatures, Ti₃O₅ is ideal for use in high-temperature processes like e-beam and thermal evaporation.

- Good Catalytic Properties: Ti₃O₅ has notable catalytic capabilities, especially in photocatalytic reactions for air and water purification.

- Durability and Hardness: Ti₃O₅ thin films are durable and resistant to wear, making them suitable for both protective and decorative purposes.

- Semiconducting Properties: With its semiconducting characteristics, Ti₃O₅ is useful in electronic components and sensor technology.

-

- High Purity: Ensures consistent and reliable thin-film quality.

- Stable Performance: Exceptional thermal and chemical stability for demanding applications.

- Customizable Configurations: Available in various sizes and forms to suit diverse deposition systems.

- Optical Clarity: Produces transparent coatings with excellent optical properties.

- Durability: High resistance to mechanical stress and environmental degradation.

-

- High Strength-to-Weight Ratio: TiAl alloys combine the lightweight nature of aluminum with the strength of titanium, making them ideal for thin films in high-performance applications.

- Corrosion and Oxidation Resistance: TiAl films provide excellent resistance to corrosion and oxidation, ensuring durability and longevity in harsh environments.

- Thermal Stability: TiAl alloys can withstand high temperatures without losing mechanical properties, making them suitable for applications in high-temperature environments.

- Good Adhesion: TiAl thin films exhibit excellent adhesion to substrates, which is crucial for semiconductor and coating applications where film integrity is vital.

- Wear Resistance: The addition of titanium improves the hardness and wear resistance of TiAl coatings, contributing to extended tool life and enhanced component durability.

-

- High Strength-to-Weight Ratio: Ideal for lightweight and robust components.

- Excellent High-Temperature Resistance: Retains strength at elevated temperatures.

- Oxidation and Corrosion Resistance: Prolongs material lifespan in harsh environments.

- Customizable Ti-Al Ratios: Tailored to meet specific industrial requirements.

- Wide Range of Particle Sizes: From nano to micrometer scales for diverse applications.

-

- High Hardness: TiB₂ has one of the highest hardness values among borides, making it ideal for creating hard coatings that resist wear and abrasion.

- Thermal Stability: It has excellent thermal conductivity and stability at high temperatures, which is critical for coatings used in high-temperature applications.

- Electrical Conductivity: TiB₂ is a good conductor of electricity, allowing its use in thin-film applications that require conductivity without sacrificing durability.

- Corrosion Resistance: TiB₂ is resistant to many corrosive environments, especially when exposed to molten metals or extreme industrial conditions.

- Strong Adhesion: TiB₂ coatings bond strongly to a variety of substrates, ensuring long-lasting performance in industrial and electronic applications.

-

- Exceptional Hardness: Highly resistant to wear and abrasion.

- High Thermal Conductivity: Ideal for heat dissipation applications.

- Excellent Corrosion Resistance: Stable in molten metals and harsh chemical environments.

- Electrical Conductivity: Suitable for conductive ceramics and electrodes.

- High Melting Point: Withstands extreme temperatures without degradation.

- Customizable Particle Size: Tailored to specific application requirements.

-

- Exceptional Hardness: Provides superior durability and wear resistance.

- High Thermal Stability: Performs well under extreme temperatures.

- Electrical Conductivity: Suitable for electronic applications requiring conductive layers.

- Corrosion Resistance: Withstands harsh chemical environments.

- High Purity: Ensures consistent thin-film quality and reliable performance.

-

- High Hardness: TiC is extremely hard, making it useful for coatings that require high wear resistance.

- Thermal Stability: TiC can withstand high temperatures, making it ideal for high-temperature deposition and coating processes.

- Corrosion Resistance: TiC coatings provide excellent resistance to oxidation and chemical corrosion, enhancing component longevity in harsh environments.

- Electrical Conductivity: As a conductive ceramic, TiC is suitable for applications requiring both mechanical strength and electrical conductivity.