Showing 601–612 of 678 results

-

- High Strength and Durability: Offers superior tensile strength and resistance to wear and tear.

- Excellent Corrosion Resistance: Effective in harsh environments, resisting oxidation and chemical degradation.

- Good Thermal Conductivity: Suitable for high-temperature applications.

- Enhanced Toughness: Performs well under stress and strain, even in extreme conditions.

- Customizable Composition: Available in different V-Fe ratios to meet specific application needs.

- Versatile Particle Sizes: Available from nanoscale to micrometer dimensions for various uses.

-

- High purity (≥99.9%).

- Exceptional thermochromic and phase-transition properties.

- Stable in controlled deposition environments.

- Uniform size and density for consistent evaporation.

- Customizable pellet sizes and compositions.

-

- Thermochromic Transition: Reversible phase transition from semiconductor to metallic state.

- High Purity: ≥99.9%, ensuring consistent material performance.

- Customizable Particle Sizes: Nano and micron grades for diverse applications.

- Temperature Responsiveness: Transition temperature around 68°C.

- Optical Modulation: Excellent modulation of infrared transmission.

- Durability: Chemically stable and resistant to environmental degradation.

-

- Phase Transition: One of the most distinctive features of VO₂ is its reversible phase transition from an insulator to a metal at around 68°C. This enables tunable electrical and optical properties, making it a versatile material in smart applications.

- Thermochromic Behavior: VO₂’s thermochromic properties are used in energy-efficient coatings that automatically adjust their transparency and reflectivity based on temperature.

- Optical Properties: VO₂ exhibits unique optical behavior, including changes in reflectivity and transmission with temperature, making it suitable for use in smart windows and optical devices.

- Electrical Properties: VO₂ switches between insulating and metallic phases, making it useful for electronic switching applications, such as transistors and memory devices.

-

- Superior Electrical Conductivity: VSi₂ is an excellent conductor of electricity, making it ideal for applications where conductive coatings are required.

- High Thermal Stability: The material maintains its integrity under high temperatures, making it suitable for high-temperature applications.

- Hardness and Durability: Known for its wear resistance, VSi₂ is used in applications that demand exceptional durability and surface hardness.

- Corrosion Resistance: Offers good resistance to corrosion, particularly in aggressive environments.

- Customizable Sizes: Available in various sizes and thicknesses to meet specific application requirements.

-

- High Melting Point: Tungsten has the highest melting point of all metals (3,422°C), making it suitable for extreme high-temperature environments.

- Thermal Stability: Excellent ability to withstand high temperatures without warping or breaking, ensuring consistent performance under heat stress.

- Corrosion Resistance: Highly resistant to chemical corrosion, particularly in reducing environments and molten metals, ensuring long-lasting use in aggressive chemical environments.

- Mechanical Strength: Very high tensile strength and hardness, ensuring that the crucible maintains its shape under both thermal and mechanical stress.

- Low Thermal Expansion: Tungsten’s low coefficient of thermal expansion minimizes cracking and deformation when subjected to rapid temperature changes.

- High Thermal Conductivity: Efficient heat distribution within the crucible helps in achieving uniform melting or material processing.

-

- High Melting Point: Tungsten has the highest melting point of any metal, around 3,422°C (6,192°F). This makes it perfect for high-temperature applications such as heat shields, aerospace components, and vacuum furnaces.

- Excellent Strength: Tungsten foil exhibits outstanding tensile strength, maintaining its integrity even under stress or at elevated temperatures. This property ensures that it is highly durable and reliable for demanding applications.

- Low Thermal Expansion: Tungsten has an extremely low coefficient of thermal expansion (CTE), which means it does not expand or contract significantly when subjected to temperature changes. This is crucial for applications requiring dimensional stability under fluctuating temperatures.

- High Density: With a density of approximately 19.25 g/cm³, tungsten is one of the heaviest metals, giving it excellent mass and stability for a variety of industrial uses.

- Corrosion Resistance: Tungsten is resistant to corrosion in most environments. It is particularly resistant to oxidation, making it suitable for applications in vacuum environments or where high chemical stability is required.

- Biocompatibility: Tungsten is biocompatible and is used in medical implants, surgical tools, and radiation shielding, where its non-reactive nature is a significant advantage.

-

- High Purity: Ensures optimal performance in sensitive applications.

- High Melting Point: Allows for use in high-temperature environments without degradation.

- Excellent Electrical Conductivity: Ideal for applications requiring effective electrical connections.

- Thermal Stability: Maintains performance under varying temperature conditions.

- Robustness: Provides durability and reliability in demanding applications.

-

- High Purity: Exceptional quality with a purity of ≥99.9%.

- High Density: Ideal for applications demanding weight and strength.

- Thermal Stability: Excellent performance at high temperatures.

- Electrical Conductivity: Superior conductivity for electronic applications.

- Versatile Applications: Suitable for industries including aerospace, defense, and medical.

-

Tungsten sputtering targets are indispensable in industries that demand materials with high thermal and electrical conductivity, exceptional strength, and stability at extreme temperatures. These properties make tungsten a critical material in electronics, aerospace, energy, and medical applications.

-

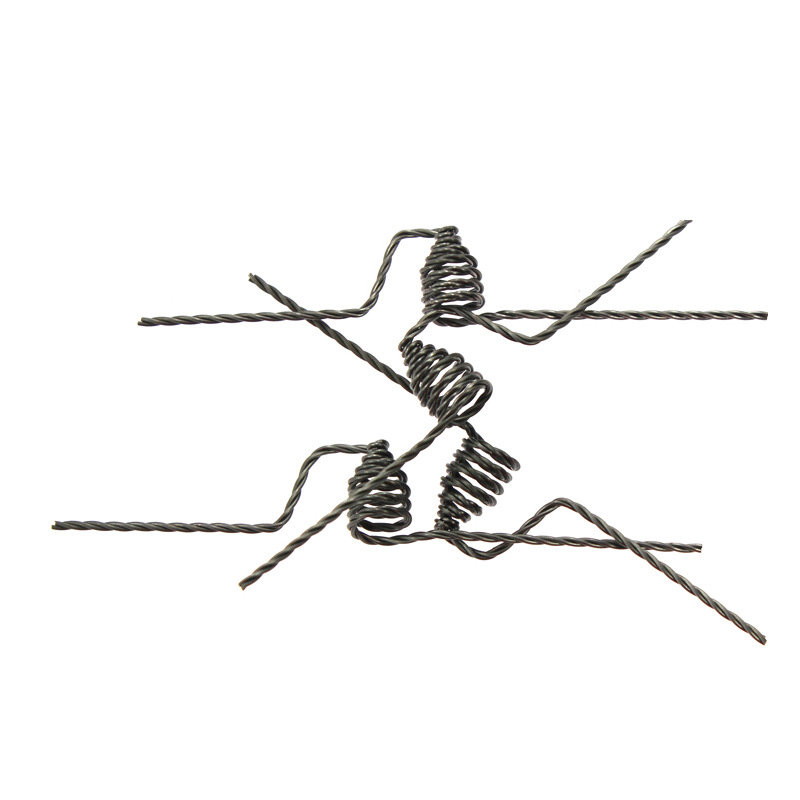

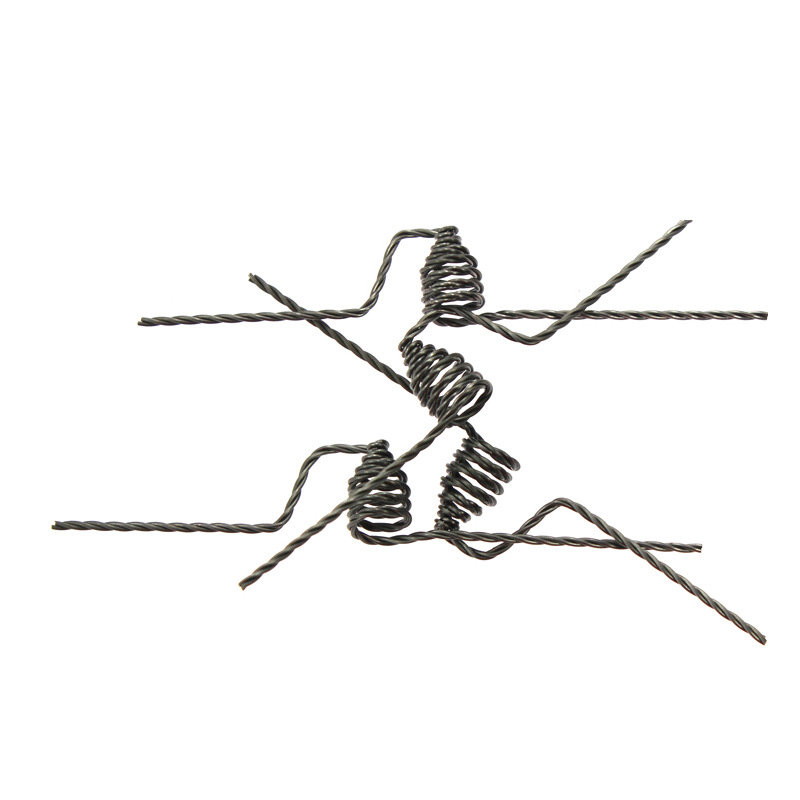

- High Melting Point: Tungsten has one of the highest melting points of any metal, at approximately 3,422°C (6,192°F). This property allows tungsten wire baskets to perform exceptionally well in high-temperature environments, such as in furnaces, aerospace applications, and high-energy industrial processes.

- Excellent Thermal Conductivity: Tungsten’s high thermal conductivity ensures that tungsten wire baskets distribute heat evenly, making them ideal for applications that require precise temperature control or rapid heat dissipation.

- Corrosion and Oxidation Resistance: Tungsten wire baskets exhibit excellent resistance to corrosion and oxidation, especially in environments with high temperatures and reactive gases. This makes them suitable for use in aggressive chemical environments where other metals may degrade.

- Mechanical Strength: Tungsten is known for its high mechanical strength and durability. Tungsten wire baskets can maintain structural integrity under high stress and heavy loads, making them suitable for industrial applications where strength and resilience are paramount.

- Density and Durability: Tungsten is a dense metal, which contributes to its durability and robustness. Tungsten wire baskets are strong yet stable, capable of supporting significant weights without deforming or losing their shape.

- Biocompatibility: Tungsten is biocompatible, making it suitable for use in medical applications. Although tungsten wire baskets are not commonly used in direct contact with biological tissues, their use in medical environments (e.g., sterilization or medical devices) requires biocompatibility.

-

- High Melting Point: With a melting point of 3422°C, tungsten wire is ideal for applications involving extreme heat.

- Exceptional Strength: Maintains high tensile strength even at elevated temperatures.

- High Density: One of the densest metals, offering robustness and durability in demanding conditions.

- Excellent Conductivity: Provides efficient thermal and electrical conductivity for industrial and electronic applications.

- Corrosion and Oxidation Resistance: Resists chemical and environmental degradation, enhancing durability.

- Low Thermal Expansion: Maintains dimensional stability under temperature fluctuations.

- Customizability: Available in various diameters, purities, and finishes to meet diverse requirements.