Showing 637–648 of 678 results

-

- High Purity: Available in purity grades of ≥99.9%.

- Thermal Stability: Excellent thermal resistance for high-temperature applications.

- Optical Properties: Ideal for use in optical fibers and laser systems.

- Chemical Resistance: Stable in various chemical environments.

- Customizable Particle Sizes: Nano (<100 nm) and micro (1–50 µm) grades available or customized.

-

- High Optical Transparency: Yb₂O₃ provides excellent transparency in the infrared region, making it ideal for IR optics and laser systems.

- Thermal and Chemical Stability: Ytterbium Oxide is thermally and chemically stable, which ensures longevity and performance in high-temperature and chemically harsh environments.

- High Purity and Low Defects: Yb₂O₃ sputtering targets are available in high-purity grades (up to 99.999%), ensuring low defect densities in the deposited thin films, critical for applications in optics and electronics.

- Rare-Earth Material: As a rare-earth oxide, Yb₂O₃ possesses unique electronic properties, making it highly valuable for specific applications in advanced technology.

-

- High Purity: ≥99.9% purity, ensuring high performance and minimal contamination in sensitive applications.

- Electrical Conductivity: Exceptional conductivity makes it ideal for use in electrical and electronic components.

- Thermal Stability: High resistance to thermal shock and high-temperature environments, retaining properties in extreme conditions.

- Chemical Resistance: Resistant to oxidation and corrosion, enhancing the longevity and reliability of components.

- Durability: Excellent wear resistance and mechanical strength, making it suitable for heavy-duty applications.

- Versatile Particle Size: Available in nano to micron-sized powders, allowing for customization based on specific application requirements.

-

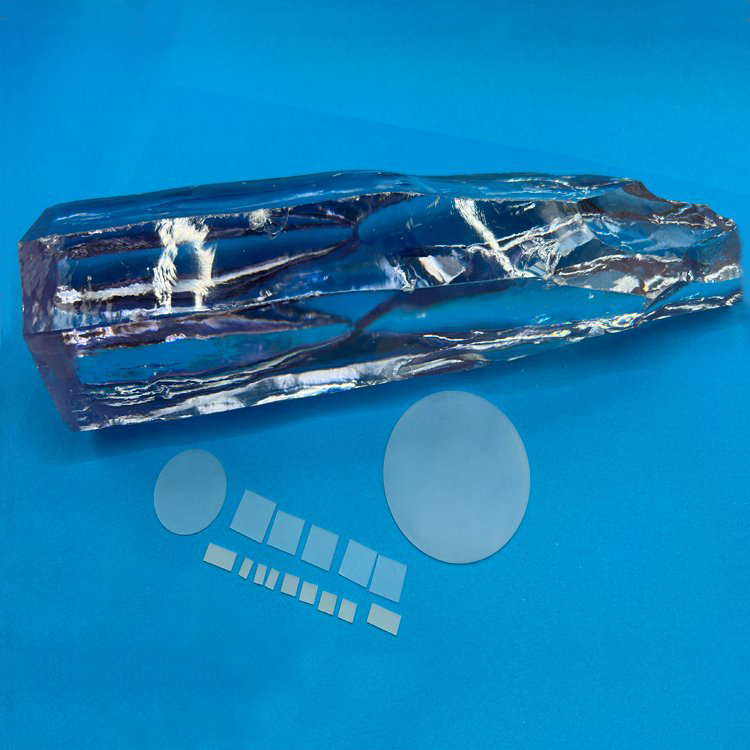

- High Transparency in IR Spectrum: YbF₃ offers exceptional transparency from the ultraviolet (UV) through to the mid-infrared (MWIR) region, making it perfect for optical applications.

- Low Refractive Index: The low refractive index of YbF₃ is beneficial for anti-reflective coatings, reducing unwanted light reflection and enhancing transmission.

- Chemical and Thermal Stability: YbF₃ is stable under high temperatures and chemically resistant, ensuring durability in harsh environments.

- Smooth Film Deposition: It provides smooth, defect-free thin films that are ideal for precise optical performance.

-

- Wide Transmission Range: Offers excellent transparency from UV (down to 200 nm) to IR (up to 10 µm), making it versatile for various optical applications.

- Low Refractive Index: Has a low refractive index (~1.5), which makes it a good material for anti-reflective coatings.

- High Chemical Stability: YF₃ is chemically inert, ensuring long-lasting coatings that resist corrosion, oxidation, and environmental wear.

- Low Absorption: Provides coatings with minimal light absorption, especially important in high-energy optical and laser systems.

- Thermal Stability: Offers good thermal stability, making it suitable for high-temperature deposition processes.

-

- Low Refractive Index: YF₃ films offer a low refractive index, making them ideal for anti-reflective coatings and optical thin films.

- High Purity: Available in ≥99.9% purity, ensuring clean deposition and minimal contamination in thin-film applications.

- Chemical Resistance: Resistant to acid and alkali, making it suitable for harsh environments.

- Optical Transparency: High optical transparency in the UV and visible spectra, enhancing the performance of optical coatings.

- Durability: Offers excellent mechanical properties and resistance to environmental degradation, ensuring long-term stability.

-

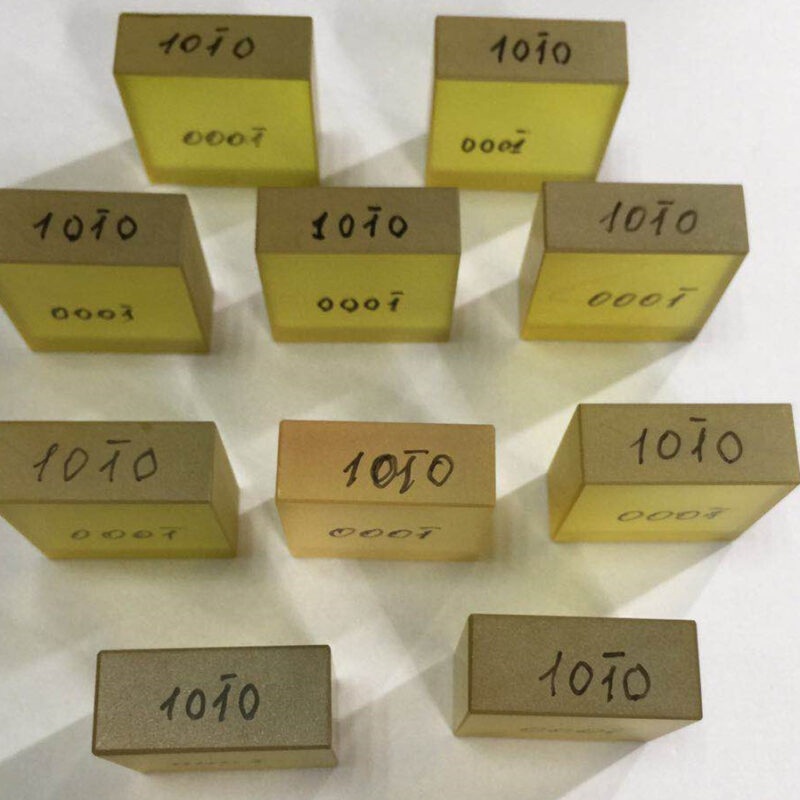

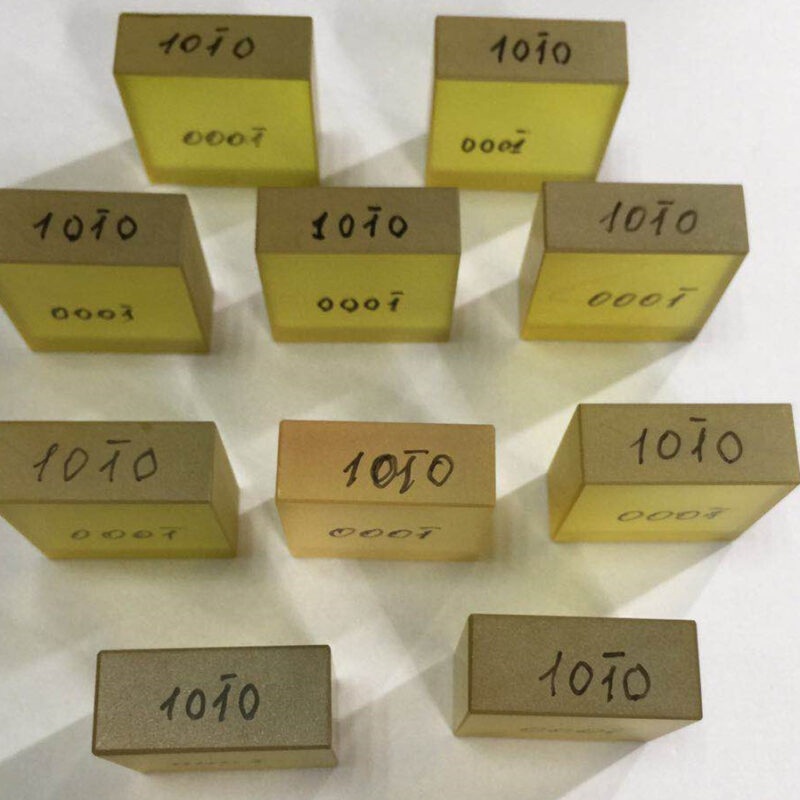

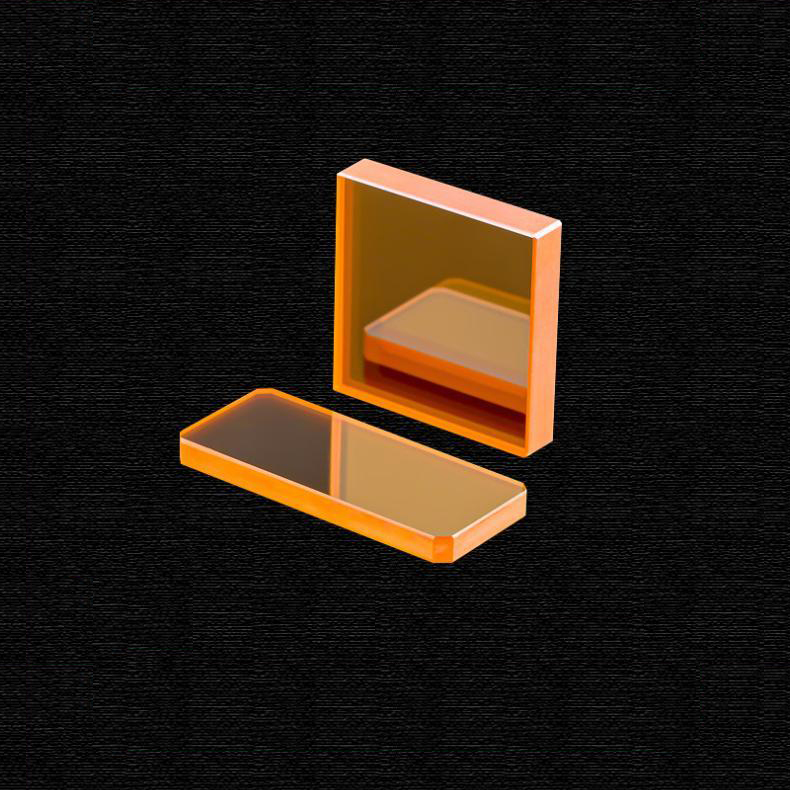

- High Thermal Stability: Suitable for high-temperature environments and laser operations.

- Excellent Mechanical Strength: Durable and resistant to cracking during processing.

- Broad Optical Transparency: Ranging from ~230 nm to 5.5 μm.

- Low Thermal Expansion Coefficient: Reduces thermal stress during device fabrication.

- High Refractive Index: Beneficial for optical and laser device efficiency.

- Good Chemical Resistance: Stable against most acids and alkalis under normal conditions.

- Low Dielectric Loss: Suitable for microwave and RF applications.

- Efficient Host Crystal: Ideal for rare-earth doping for laser crystals (e.g., Nd:YAP lasers).

-

-

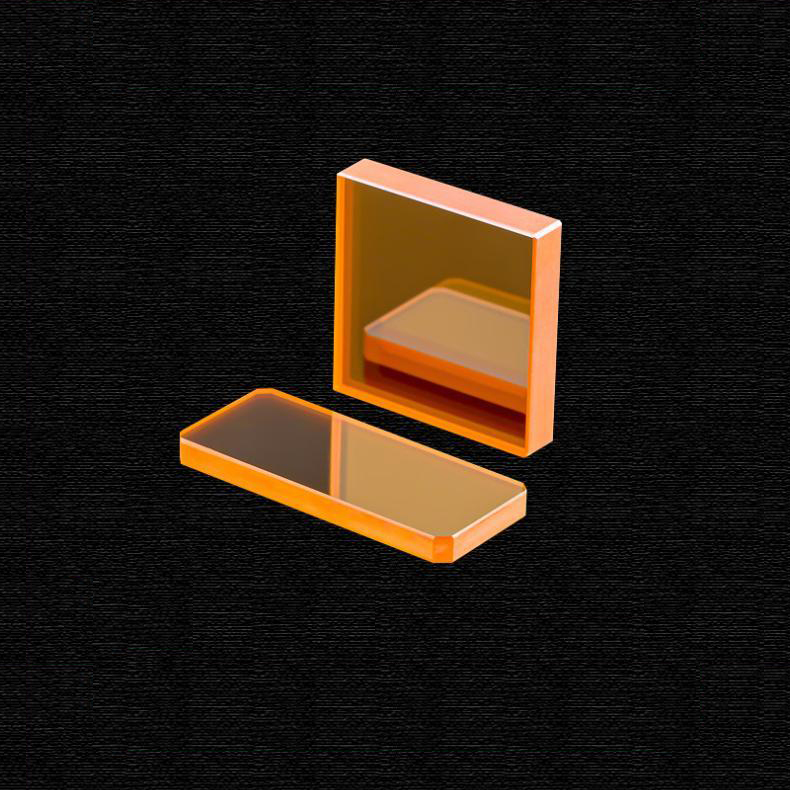

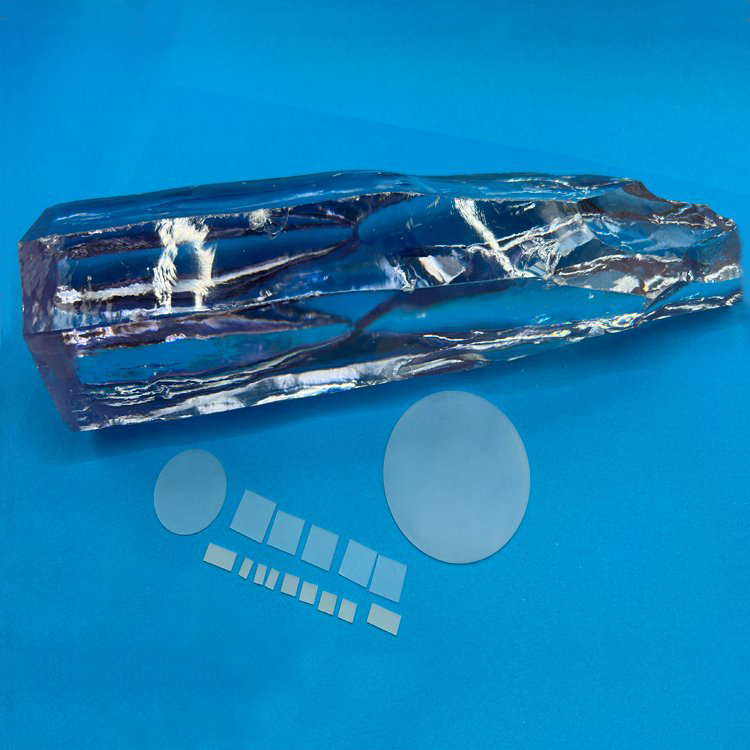

- Broad Infrared Transmission: Covers visible to far-IR regions (0.5–22 μm).

- High Refractive Index: Suitable for focusing and imaging applications.

- Low Bulk Absorption: Enables high-power CO₂ laser operation.

- Excellent Thermal Shock Resistance: Suitable for high-power, high-temperature environments.

- Chemical Stability: Resistant to moisture and most chemicals in ambient environments.

- Isotropic Optical Properties: Minimal birefringence effects.

- High Damage Threshold: Ideal for high-power laser optics and windows.

- Good Mechanical Strength: Though softer than sapphire, sufficient for most optical setups.

- Compatible with Anti-Reflection (AR) and Protective Coatings: Enhances performance and durability.

-

$255.00 – $565.00

- High purity 99.99% ZnS for stable and reproducible thin film deposition

- Excellent optical and infrared performance, suitable for IR coatings

- Multiple standard diameters compatible with most magnetron sputtering systems

- Copper backing plate options for improved thermal conductivity

- Magnetic spacer options for enhanced compatibility with magnetron cathodes

- Low impurity levels and high material density

- Customizable specifications for R&D and production use

-

- High Thermal Stability: Outstanding resistance to high temperatures up to 2500°C.

- Exceptional Mechanical Properties: High hardness, high fracture toughness, and high wear resistance.

- Excellent Ionic Conductivity: Suitable for solid oxide fuel cell (SOFC) applications.

- Low Thermal Conductivity: Ideal for thermal barrier coatings.

- Wide Optical Transmission Range: Transparent from visible to mid-IR (approximately 0.3 – 5 μm depending on doping and phase).

- Chemical Resistance: Highly resistant to corrosion, oxidation, and chemical attack.

- Various Crystal Phases Available: Including cubic-stabilized zirconia (YSZ) and tetragonal zirconia.

-

- Corrosion Resistance: Zinc is known for its excellent corrosion resistance, especially in moist environments. It forms a protective oxide layer that shields the material from further corrosion, making it ideal for use in outdoor and harsh environmental conditions.

- Electrical Conductivity: Although not as conductive as copper or aluminum, zinc foil still offers good electrical conductivity, making it suitable for applications in electrical components, such as batteries and capacitors.

- Thermal Conductivity: Zinc has relatively high thermal conductivity, making zinc foil useful in heat dissipation applications, particularly in electronics and industrial processes where temperature control is critical.

- Malleability and Flexibility: Zinc foil is highly malleable, allowing it to be easily shaped and fabricated into thin, flexible sheets. This makes it suitable for a variety of industrial applications requiring precise material manipulation.

- Non-Toxicity and Biocompatibility: Zinc is a biocompatible metal, meaning it can be used in medical and food-related applications without adverse effects. It is also non-toxic, which adds to its safety and versatility in various industries.

- Antimicrobial Properties: Zinc has natural antimicrobial properties, making zinc foil valuable in applications where hygiene and contamination control are critical, such as in medical equipment and food packaging.