Showing 673–678 of 678 results

-

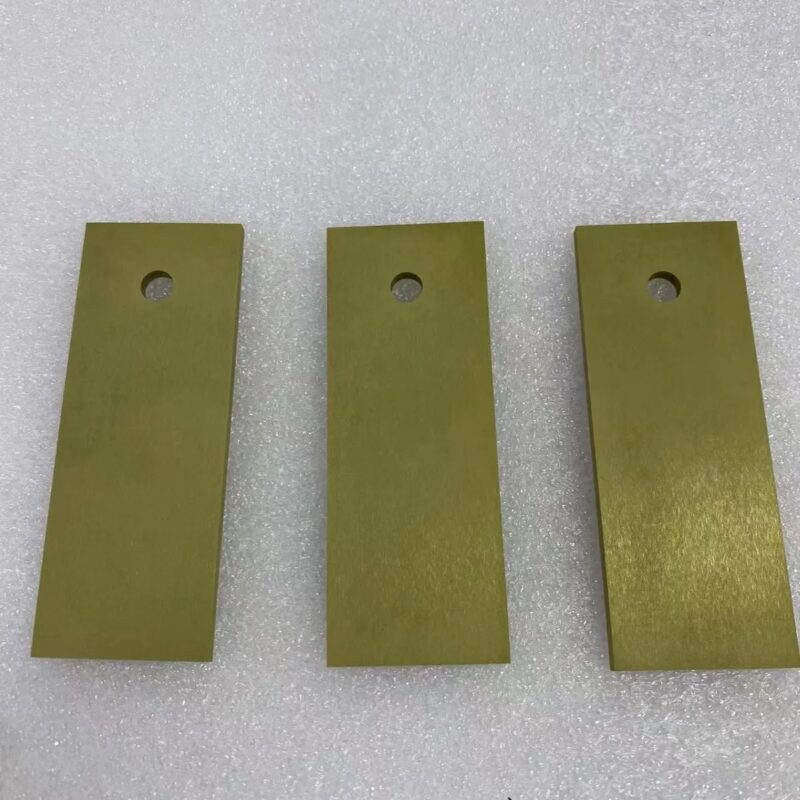

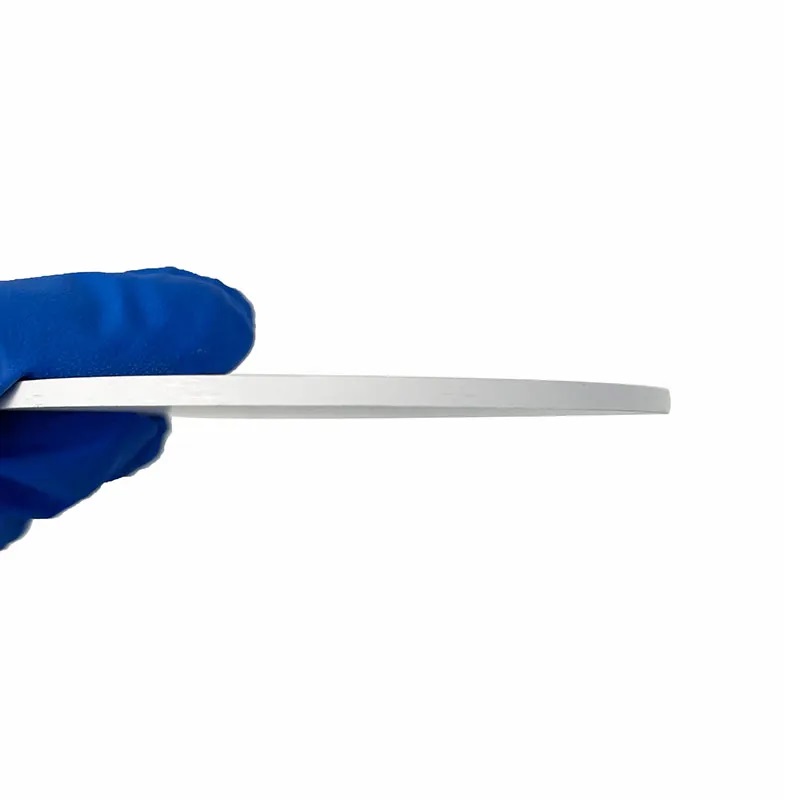

- High Hardness and Wear Resistance: ZrN is extremely hard, providing excellent resistance to wear and abrasion, making it ideal for coating cutting tools and other high-wear applications.

- Golden Metallic Appearance: ZrN’s distinct gold color makes it popular for decorative finishes in jewelry and consumer electronics.

- Thermal Stability: ZrN can withstand high temperatures, making it suitable for high-temperature coatings in industrial and aerospace applications.

- Corrosion and Oxidation Resistance: ZrN is highly resistant to corrosion, oxidation, and chemical attack, ensuring long-lasting protection in harsh environments.

- Good Conductivity: ZrN exhibits metallic-like electrical conductivity, making it suitable for electronic applications.

- Low Friction Coating: Provides a low coefficient of friction, reducing wear and improving efficiency in moving parts.

-

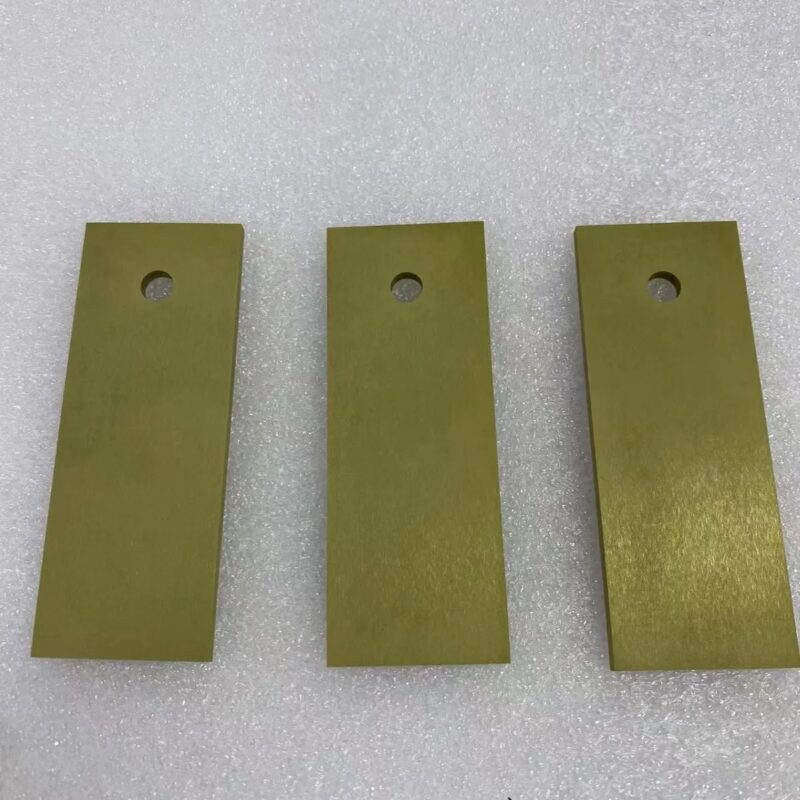

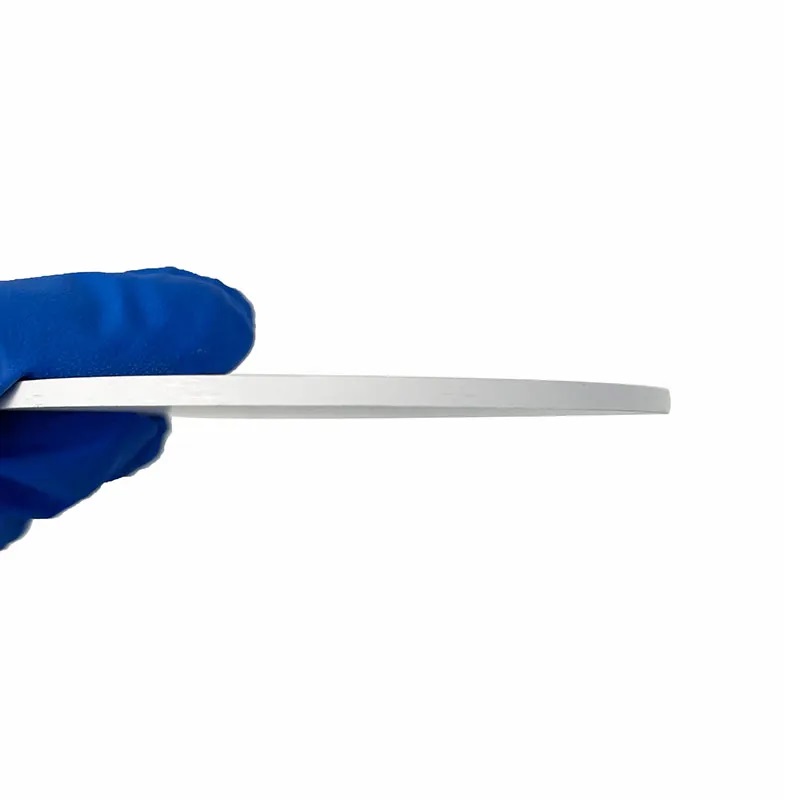

- High Hardness: ZrN films exhibit high hardness, making them ideal for protective coatings on cutting tools and wear-resistant applications.

- Corrosion and Oxidation Resistance: ZrN provides excellent resistance to chemical corrosion and oxidation, ensuring longevity and performance in harsh environments.

- Golden Color: ZrN coatings have a gold-like appearance, making them popular for decorative purposes.

- High Thermal Stability: ZrN sputtering targets produce films that can withstand high temperatures, making them suitable for aerospace and semiconductor applications.

- Good Electrical Conductivity: ZrN is electrically conductive, which allows it to be used in some electronic and microelectronic applications.

-

- High Refractive Index: ZrO2 has a high refractive index (~2.0-2.2), making it ideal for optical coatings, especially in multi-layer thin films.

- Excellent Thermal Stability: ZrO2 can withstand high temperatures, making it suitable for thermal barrier coatings and high-temperature applications.

- Corrosion and Wear Resistance: Zirconia is highly resistant to wear, corrosion, and chemical attack, providing long-lasting protection for coated components.

- Low Thermal Conductivity: ZrO2 has low thermal conductivity, making it an excellent material for insulating coatings in high-temperature environments.

- High Hardness: Zirconia is extremely hard, providing excellent mechanical strength and durability in protective and functional coatings.

- Biocompatibility: ZrO2 is non-toxic and biocompatible, making it suitable for biomedical coatings and implants.

-

- High Purity: ≥99.9% purity, ensuring excellent performance and minimal contamination in sensitive applications.

- Superior Mechanical Properties: Exceptional hardness, wear resistance, and toughness, making it ideal for demanding industrial environments.

- High Thermal Stability: Resistant to high temperatures, making it suitable for applications in extreme thermal conditions.

- Excellent Chemical Inertness: Resistant to corrosion and chemical attacks, making it useful in a wide range of industrial processes.

- Versatile Particle Size: Available in a range of particle sizes, from nano to micron scale, allowing for customization to suit specific application needs.

- Biocompatibility: Non-toxic and biocompatible, which makes it ideal for medical and dental applications.

-

- High Refractive Index: ZrO₂ has a high refractive index, making it ideal for optical coatings where enhanced light control and reflection properties are needed.

- Dielectric Properties: ZrO₂ exhibits a high dielectric constant, which is critical for its use in electronic and semiconductor applications.

- Thermal Stability: ZrO₂ can withstand extreme temperatures, making it suitable for use in high-temperature coatings and thermal barrier applications.

- Wear Resistance: ZrO₂ films provide excellent hardness and wear resistance, extending the life of coated components in industrial and aerospace environments.

- Corrosion Resistance: The chemical inertness of ZrO₂ makes it resistant to corrosion, which is important in applications exposed to harsh chemicals or environmental conditions.

-

- High-Temperature Resistance: Zirconia crucibles can withstand temperatures up to 3000°C, making them suitable for applications involving molten metals, ceramics, and other high-temperature processes.

- Exceptional Thermal Stability: With a low thermal expansion coefficient, zirconia maintains structural integrity under rapid temperature fluctuations, making it ideal for high-temperature melting and casting.

- Chemical Inertness: Zirconia crucibles are highly resistant to chemical attack, including resistance to strong acids and molten metals, ensuring minimal contamination of materials and extended service life.

- Mechanical Strength: Zirconia exhibits excellent mechanical properties, including high hardness and resistance to cracking, ensuring the crucible’s durability in demanding applications.

- High Density: Zirconia has a high density, which helps improve its thermal conductivity and resistance to deformation under high pressures and temperatures.

- Electrical Insulation: Zirconia crucibles possess excellent electrical insulation properties, which can be crucial in applications where electrical conductivity must be minimized.