Showing 193–204 of 252 results

-

- High Purity: Manufactured with stringent quality controls to ensure material integrity and minimal impurities.

- Customizable Options: Available in various sizes, thicknesses, and shapes to meet specific deposition requirements.

- Excellent Physical Properties: Offers reliable electrical and optical performance.

- Versatile Compatibility: Suitable for advanced sputtering systems.

-

- High Electrical Conductivity: SrRuO₃ films provide excellent electrical conductivity, making them ideal for use as electrodes and contact layers.

- Stability: Offers good stability under various operating conditions, making it suitable for use in demanding applications.

- Magnetic Properties: Exhibits magnetic properties, making it useful in devices that require the integration of magnetic and electronic functions.

- Compatible with Other Oxides: SrRuO₃ can be easily integrated with other perovskite oxide materials, making it versatile for various electronic applications.

- High Purity: Available in high-purity grades (≥99.9%) to ensure clean and consistent thin-film deposition.

-

- High Purity: Ensures superior film quality and uniform deposition.

- Optimal Conductivity: Suitable for advanced optoelectronic devices.

- Customization: Available in various sizes, shapes, and compositions to meet specific requirements.

- Stability: Excellent thermal and chemical stability for long-lasting performance.

-

- High Purity: Typically ≥99.9% for superior film quality and performance

- Excellent Dielectric Properties: Ideal for high-frequency electronic applications

- Perovskite Structure: Ensures compatibility with complex oxide thin films

- Customizable: Available in various sizes and shapes to suit specific requirements

- Durability: High thermal and chemical stability for long-term use

-

- High Conductivity: Excellent electrical conductivity makes SrVO₃ ideal for applications requiring transparent conductive materials.

- High Purity: Available in ≥99.5% purity, ensuring high-quality thin-film deposition.

- Stable Sputtering Performance: Reliable and consistent sputtering performance with minimal target degradation.

- Optical Transparency: Ideal for optoelectronic devices requiring both electrical conductivity and optical transparency.

- Customization: Targets can be made in various sizes and shapes to meet specific deposition system requirements.

-

- High Purity: Ensures contamination-free thin films for critical applications.

- Corrosion Resistance: Withstands harsh chemical environments.

- High Melting Point: Stable under extreme thermal conditions.

- Superior Electrical Conductivity: Suitable for advanced electronic devices.

- Customizable Options: Adaptable to specific design and operational requirements.

-

- High Dielectric Constant: Ta₂O₅ films exhibit a high dielectric constant, making them ideal for use in capacitors and semiconductor devices requiring high electrical insulation.

- Chemical and Thermal Stability: Ta₂O₅ provides excellent resistance to chemical attack and can withstand high temperatures, making it suitable for applications in harsh environments.

- Optical Transparency: Ta₂O₅ is transparent over a wide range of wavelengths, which makes it an excellent material for optical coatings that require high refractive index and low absorption.

- High Refractive Index: The high refractive index of Ta₂O₅ makes it ideal for optical multilayer coatings used in anti-reflective applications and optical filters.

- Durability: Ta₂O₅ films are known for their mechanical strength and durability, providing a robust protective layer in various high-performance applications.

-

- Extreme Hardness: TaC coatings provide excellent hardness, making them ideal for cutting tools, wear-resistant coatings, and surfaces exposed to high friction.

- High Melting Point: With a melting point exceeding 3880°C, TaC is one of the most heat-resistant materials, suitable for high-temperature applications in aerospace and industrial processes.

- Corrosion Resistance: TaC films offer robust resistance to chemicals, making them ideal for protective coatings in chemically aggressive environments.

- Electrical Conductivity: TaC has good electrical conductivity, which is advantageous in certain electronic and semiconductor applications.

- Oxidation Resistance: The oxidation resistance of TaC enhances its performance in environments where exposure to high temperatures and reactive gases is common.

-

- Excellent Diffusion Barrier: TaN films provide an effective barrier against the diffusion of metals, such as copper, making them crucial for semiconductor devices.

- High Electrical Resistivity: TaN has a relatively high electrical resistivity, which makes it suitable for thin-film resistors and other resistive applications.

- Chemical and Thermal Stability: Tantalum Nitride exhibits excellent stability in extreme chemical and thermal environments, ensuring long-lasting performance in harsh conditions.

- Hardness and Wear Resistance: TaN films offer superior hardness and wear resistance, making them ideal for protective coatings in demanding industrial applications.

- Corrosion Resistance: TaN is resistant to corrosion, making it suitable for use in environments where exposure to chemicals or moisture is a concern.

-

Terbium sputtering targets are essential in the production of thin films with unique magnetic and optical properties, making them invaluable in advanced technologies such as magneto-optic devices, magnetic refrigeration, data storage, and high-performance displays. Despite its rarity, terbium’s distinct characteristics offer significant advantages in specialized industrial and technological applications.

-

- Excellent Photovoltaic Properties: TeCd, especially CdTe, is widely used in thin-film solar cells due to its excellent light absorption and efficient energy conversion.

- Infrared Sensitivity: TeCd thin films exhibit high sensitivity to infrared light, making them suitable for infrared detectors and thermal imaging devices.

- Stable Thin Films: TeCd films are chemically stable and durable, ensuring long-term performance in harsh environmental conditions.

- Efficient Energy Conversion: TeCd materials offer high energy conversion efficiency, particularly in solar and thermoelectric applications, providing reliable performance in energy devices.

-

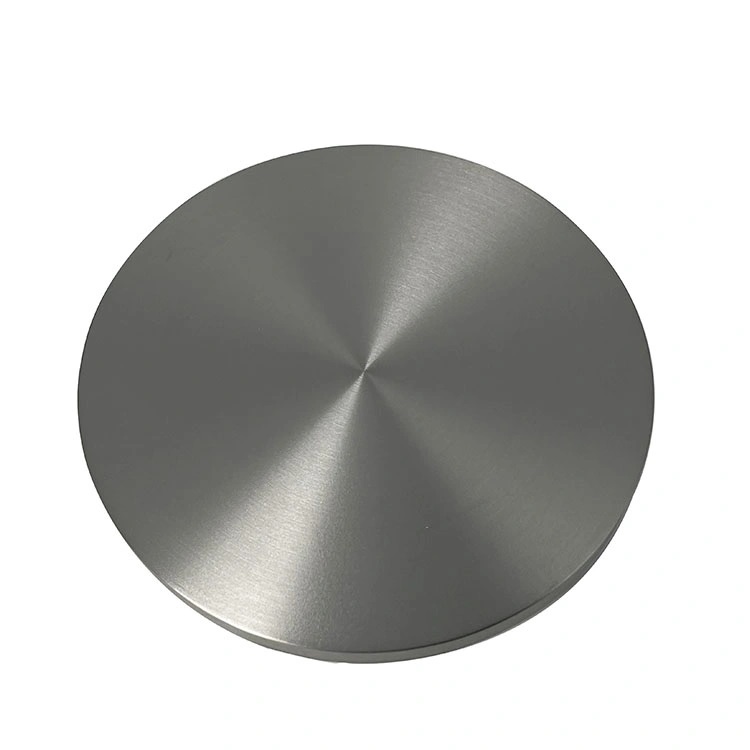

Titanium (Ti) sputtering targets are widely used in physical vapor deposition (PVD) processes to create thin films and coatings on various substrates. Titanium is known for its high strength-to-weight ratio, excellent corrosion resistance, and ability to form strong bonds with a variety of materials, making it an ideal choice for many industrial applications.