Showing 61–72 of 252 results

-

- Excellent Electrical and Thermal Conductivity: The copper base ensures superior electrical and thermal conductivity, making it ideal for electronic applications.

- Corrosion Resistance: The addition of nickel and titanium enhances the alloy’s resistance to corrosion, ensuring the longevity of thin films in harsh environments.

- High Strength and Durability: Titanium adds mechanical strength to the alloy, while nickel contributes to its hardness and wear resistance, making it suitable for demanding applications.

- Thermal Stability: CuNiTi alloys maintain their properties at elevated temperatures, making them ideal for high-temperature processes and environments.

- Customizable Properties: The ratio of copper, nickel, and titanium can be adjusted to tailor the alloy’s specific properties for a wide range of applications.

-

- Narrow Bandgap: CuO is a p-type semiconductor with a narrow bandgap (~1.2-1.7 eV), making it suitable for absorbing visible light, ideal for solar energy and semiconductor applications.

- High Absorption: CuO exhibits excellent light absorption in the visible range, enhancing its efficiency in photovoltaic cells and other optical applications.

- Chemical Stability: CuO thin films are highly stable, offering long-lasting performance in various environmental conditions.

- Customizable: CuO sputtering targets can be tailored in size, shape, and purity to fit specific deposition systems and applications.

-

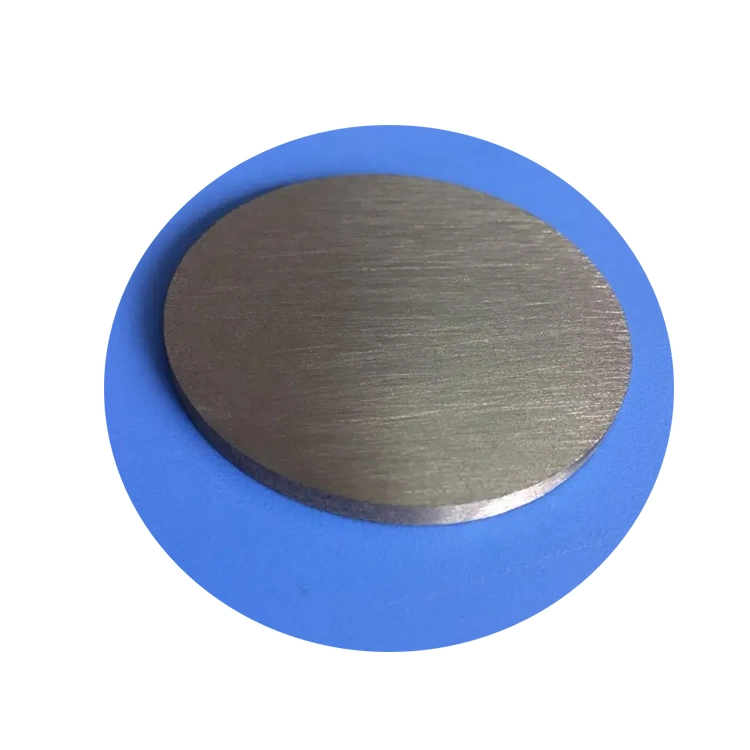

- Semiconductor Properties: CuS is a p-type semiconductor, making it suitable for applications in photovoltaics and semiconductor devices.

- High Absorption: Copper Sulfide has strong light absorption characteristics, especially in the visible spectrum, making it ideal for solar energy applications.

- Customizable: CuS sputtering targets can be customized in terms of size, purity, and bonding options to meet specific deposition requirements.

- High Chemical Stability: CuS is chemically stable, which ensures the longevity and durability of the deposited thin films.

-

- High Purity: Ensures defect-free deposition for precision applications.

- Good Electrical Conductivity: Suitable for functional and conductive coatings.

- Stable Performance: Maintains chemical and thermal stability during sputtering processes.

- Customizable: Available in various dimensions and shapes for compatibility with sputtering systems.

-

- Purity: Typically available in 99.9% or higher purity to ensure excellent thin film quality.

- Magnetic Properties: Dysprosium enhances the magnetic performance of thin films, making it ideal for applications that require strong and stable magnetic fields.

- Thermal Stability: Dy thin films maintain stability at high temperatures, making them suitable for use in thermal management applications.

- Customization: Available in various shapes, such as discs, plates, and cylinders, to meet the needs of different sputtering systems.

-

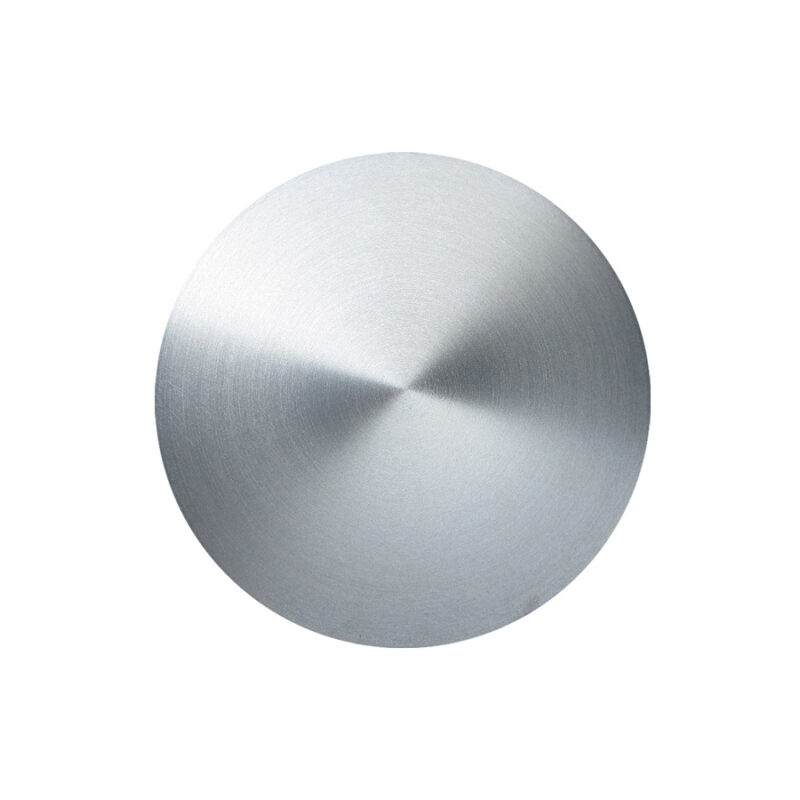

- Material: High-purity Erbium, typically with a purity level of 99.9% (3N) or higher, ensures minimal impurities during the sputtering process.

- Form: Erbium sputtering targets are commonly available in the form of discs, rectangular plates, or custom shapes, depending on specific application requirements.

- Density: The target’s density is critical for achieving consistent deposition rates and high-quality thin films.

- Applications: These targets are used in applications such as optical amplifiers, lasers, telecommunications, and electronic devices.

-

- High Infrared Transparency: Er₂O₃ has excellent transparency in the infrared range, making it a critical material for fiber-optic communications, laser systems, and IR detectors.

- Optical Amplification: The presence of erbium ions in Er₂O₃ allows for efficient optical amplification in the telecommunications band around 1.55 µm, making it ideal for use in EDFAs.

- Thermal Stability: Er₂O₃ sputtering targets provide thin films that are thermally stable and chemically inert, suitable for high-temperature applications.

- Customizability: Er₂O₃ sputtering targets can be customized to meet specific deposition needs, including different geometries, sizes, and purity levels for improved thin-film performance.

-

- Strong Luminescence: Eu₂O₃ is widely recognized for its luminescent properties, particularly its emission in the red spectrum, making it ideal for use in display technologies and lighting.

- Stable Thin Films: Europium oxide thin films provide excellent chemical stability and durability, ensuring long-lasting performance in devices exposed to various environmental conditions.

- Optical Transparency: Eu₂O₃ exhibits good optical transparency in specific wavelengths, enhancing its performance in optical applications, from phosphors to light-emitting devices.

- High Purity: High-purity Eu₂O₃ targets (up to 99.99%) ensure optimal performance in thin-film deposition processes, especially in high-tech applications such as displays and optoelectronics.

-

Iron (Fe Ferrum) sputtering targets are essential for industries that rely on the unique magnetic, electrical, and structural properties of iron, making them indispensable in magnetic storage, electronics, industrial coatings, and advanced material applications.

-

- High Purity: Fe₂O₃ sputtering targets are available in high-purity formulations to ensure optimal thin film quality for precise applications.

- Magnetic Properties: The material exhibits ferrimagnetism, making it suitable for magnetic thin films and spintronic applications.

- Semiconductor Properties: As a semiconductor, Fe₂O₃ is used in photocatalysis and solar cells, where it can absorb sunlight and drive photoelectrochemical reactions.

- Environmental Stability: Fe₂O₃ is chemically stable and exhibits good performance in a range of environmental conditions, enhancing its use in sensors and energy applications.

-

- High Purity: Guarantees consistent deposition and minimal contamination in thin films.

- Strong Magnetic Properties: Provides excellent performance in magnetic and spintronic devices.

- High Electrical Conductivity: Enhances the functionality of conductive thin films.

- Customizable Dimensions: Manufactured to meet the requirements of diverse sputtering systems.

- Versatile Material: Suitable for applications ranging from electronics to biomedical engineering.

-

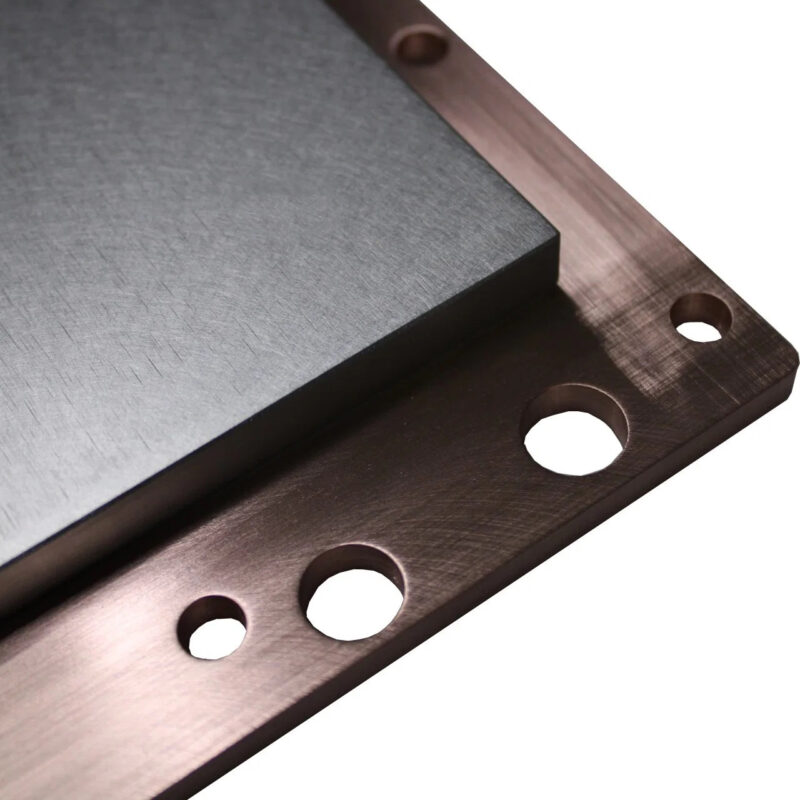

- High Entropy Alloy: The near-equal combination of five elements offers unique mechanical and thermal properties, including high strength, excellent wear resistance, and thermal stability.

- Corrosion Resistance: The alloy’s thin films offer exceptional resistance to oxidation and corrosion, even in harsh environments.

- Magnetic Properties: FeCoCrNiMn alloy sputtering targets produce films with strong magnetic properties, ideal for magnetic and electronic devices.

- Customizable Size and Shape: FeCoCrNiMn alloy sputtering targets are available in discs, plates, or custom shapes to meet the requirements of different deposition systems.