View cart “KTN Crystal (KTa₀.₅Nb₀.₅O₃) – Orientation, 10 × 10 × 0.5 mm” has been added to your cart.

Showing 289–300 of 677 results

-

- High Purity: ≥99.95% for reliable and consistent performance.

- Exceptional Corrosion Resistance: Unaffected by acids and extreme environments.

- High Melting Point: Withstands temperatures exceeding 2,400°C.

- Chemical Inertness: Stable in various chemical environments.

- Fine Particle Size: Customizable sizes to meet specific application needs.

- Superior Electrical Properties: Ideal for applications requiring excellent conductivity.

-

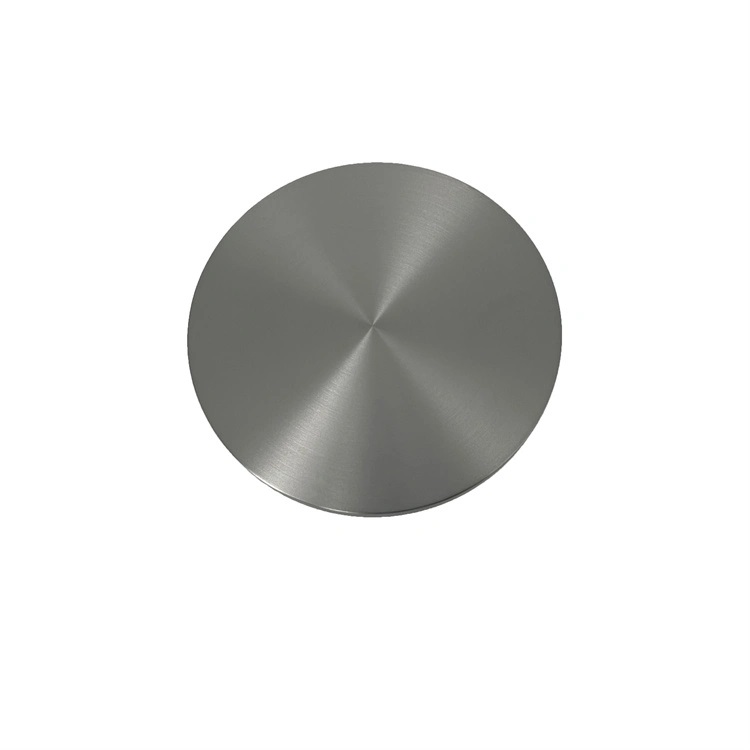

- High Purity: Iridium sputtering targets are available in ultra-high purity (up to 99.99%) to ensure the deposition of superior thin films for sensitive electronics and optical components.

- Thermal Stability: Iridium’s high melting point (~2446°C) makes it ideal for thin films that must withstand extreme heat in aerospace, semiconductor, and other high-temperature environments.

- Corrosion Resistance: Iridium is one of the most corrosion-resistant metals, ensuring long-lasting films in harsh chemical environments.

- Electrical Conductivity: Iridium thin films offer excellent electrical conductivity, making them essential for electronic applications requiring efficient current flow.

- Customizable Size and Shape: Available in various forms, including discs, plates, and custom geometries, to fit different PVD systems.

-

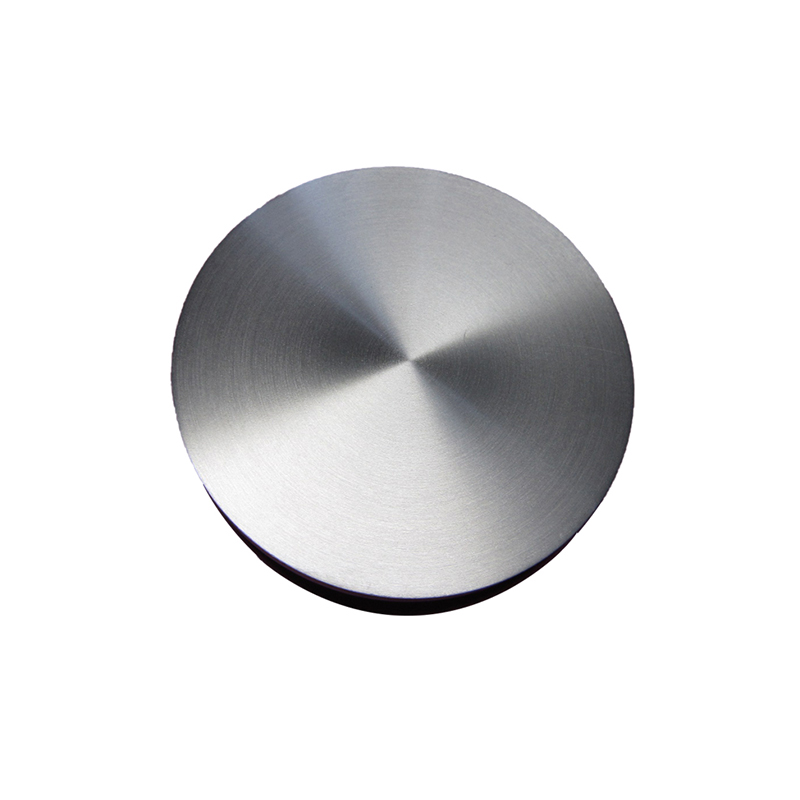

- Antiferromagnetic Properties: IrMn alloy thin films exhibit strong antiferromagnetic behavior, which is essential for magnetic pinning in spintronic devices and memory storage.

- High Corrosion Resistance: Iridium provides excellent corrosion resistance, ensuring the durability and longevity of the deposited thin films, even in harsh environments.

- Thermal Stability: IrMn alloy films are thermally stable, making them ideal for high-temperature applications in electronic and magnetic devices.

- Customizable Size and Shape: IrMn sputtering targets are available in various sizes and shapes, including discs, plates, and custom geometries, to suit a wide range of deposition systems.

-

$100.00 – $780.00

- High Electrical Conductivity: ITO films exhibit excellent electrical conductivity, allowing for efficient electron transport in devices like displays, sensors, and solar cells.

- Optical Transparency: ITO combines electrical conductivity with high transparency in the visible spectrum, making it essential for devices that require a clear view, such as displays and touchscreens.

- Wide Bandgap (3.5-4.3 eV): The wide bandgap of ITO makes it suitable for transparent conducting electrodes, ensuring minimal interference with visible light.

- Durability: ITO coatings are robust and can withstand environmental stress, including UV exposure and high temperatures, ensuring long-lasting performance.

- Customizable Conductivity and Transparency: The ratio of indium to tin can be adjusted to optimize the balance between conductivity and transparency based on the specific application needs.

-

- High Transparency and Conductivity: ITO offers a balance of excellent transparency in the visible spectrum and good electrical conductivity, making it a perfect material for applications requiring both.

- Adjustable Stoichiometry: The ratio of In2O3 to SnO2 in ITO can be adjusted to optimize its electrical and optical properties for specific applications.

- Thin-film Uniformity: ITO films are known for their uniform thickness and quality, essential for ensuring consistent performance across large-area coatings like touchscreens and solar panels.

- Durability: ITO films are chemically stable and durable, providing long-term performance in various environmental conditions.

- Custom Purity Levels: ITO sputtering targets are available in a variety of purities (up to 99.999%) to meet the stringent requirements of high-performance electronic and optical devices.

-

- High Optical Transparency: Enables the creation of efficient transparent films.

- Superior Conductivity: Provides excellent electrical performance for electronic applications.

- Thermal and Chemical Stability: Ensures reliability in high-temperature and reactive environments.

- Customizable Material Composition: Optimized for specific TCO requirements.

- Compatibility: Suitable for RF and DC sputtering systems.

-

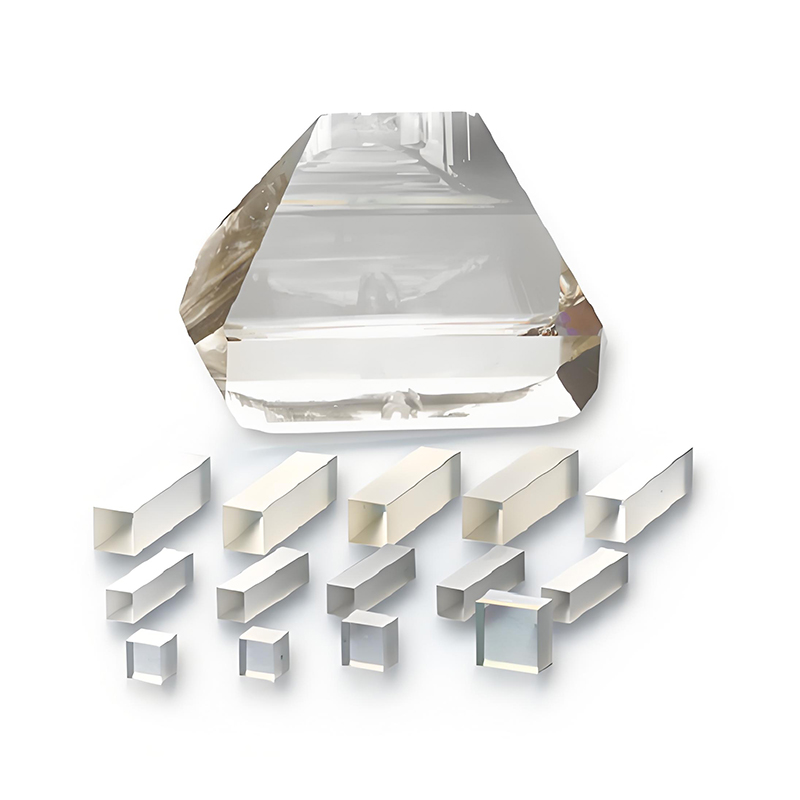

- Exceptional Electro-Optic Performance: Extremely high electro-optic coefficients enabling high-speed modulation and tunable devices.

- High Dielectric Constant: Useful for applications in capacitors and tunable microwave devices.

- Wide Transparency Range: Optical transmission from near-UV (~400 nm) to mid-IR (~5.5 μm).

- Tunable Refractive Index: Ability to electrically modulate optical properties.

- Low Optical Absorption: High transmission and low loss across the IR and visible spectrum.

- Precise Composition Control: Customizable Nb/Ta ratios (x values) to tailor ferroelectric and optical properties.

- Good Chemical Stability: Suitable for long-term operation in standard laboratory environments.

-

$1,285.00

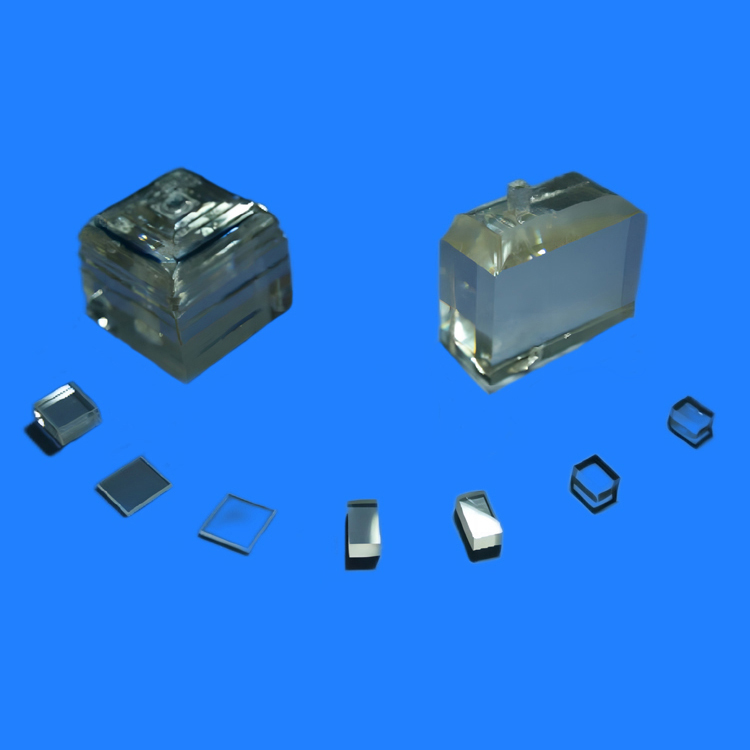

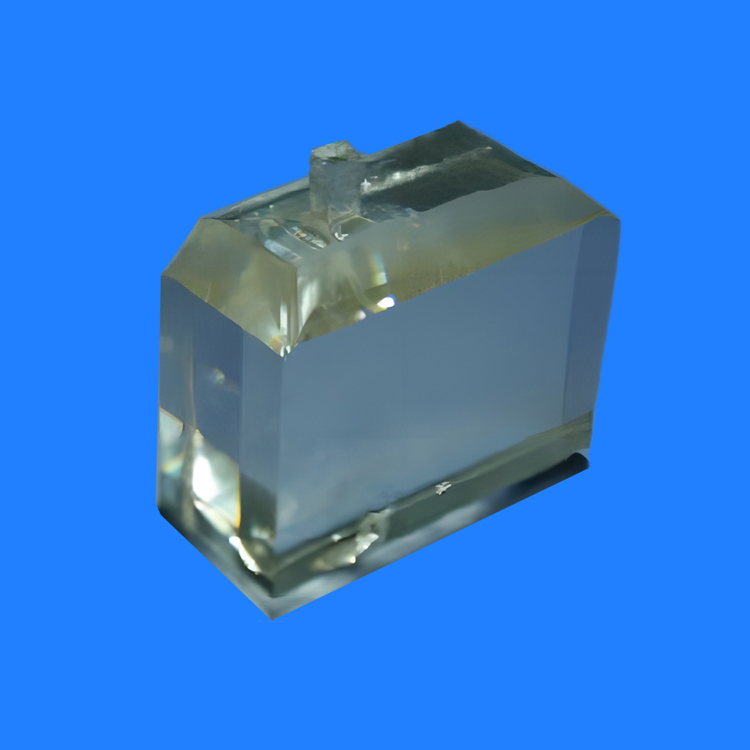

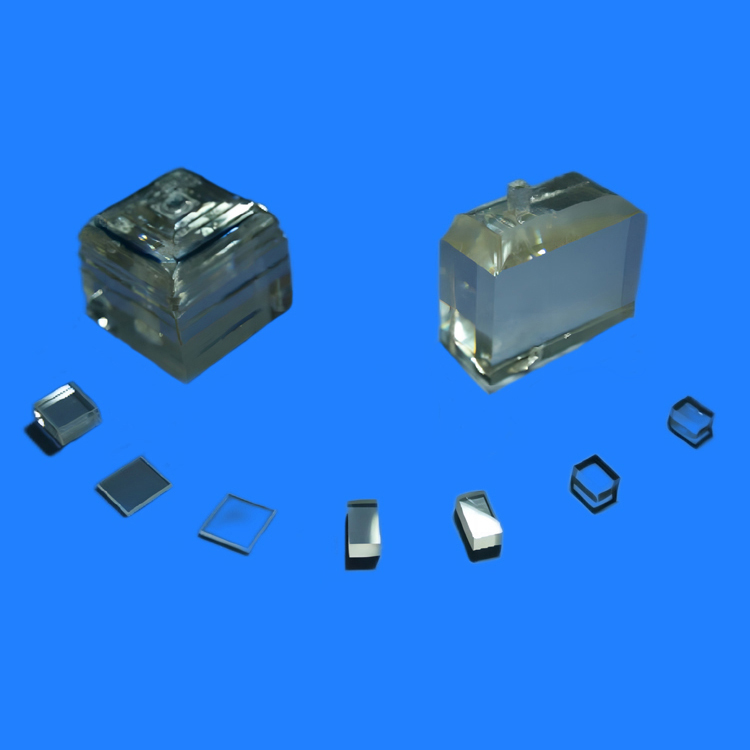

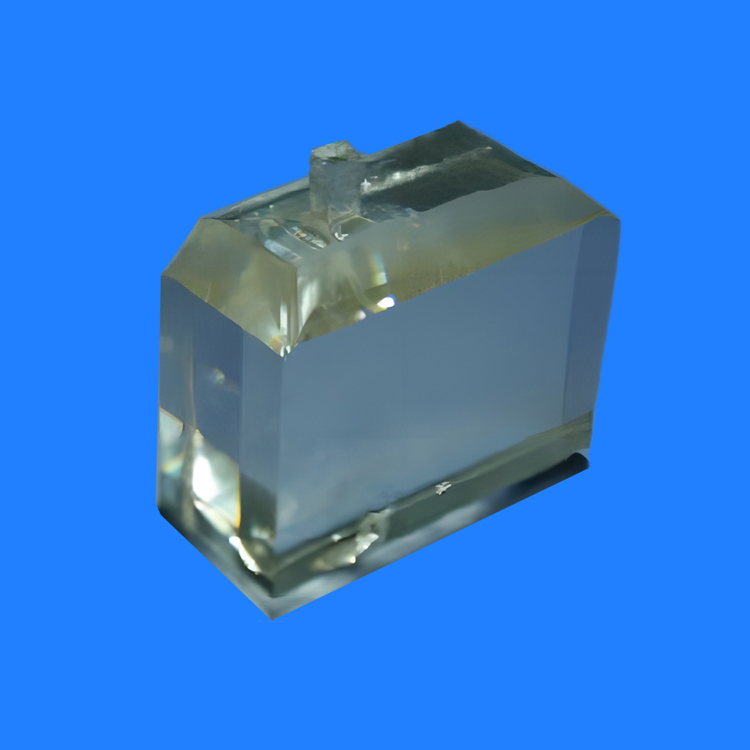

- Single crystal KTN with composition KTa₀.₅Nb₀.₅O₃

- <001> crystallographic orientation for optimal electro-optic performance

- Size: 10 × 10 × 0.5 mm

- High electro-optic coefficient (r33 ≈ 30–50 pm/V)

- Strong photorefractive effect

- Excellent dielectric tunability

- Wide optical transparency (~350 nm – 5500 nm)

- Low defect density and high optical uniformity

-

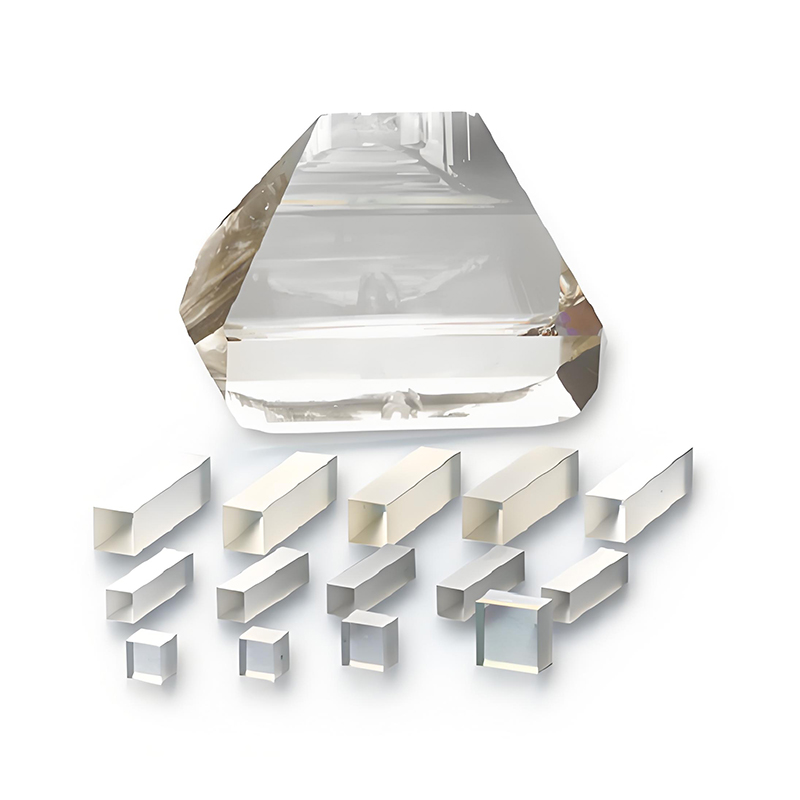

- High Nonlinear Optical Coefficient: ~15 times that of KDP crystals.

- Broad Transparency Range: 350 nm to 4500 nm.

- High Damage Threshold: >500 MW/cm² for nanosecond pulses.

- Excellent Electro-optic Properties: Suitable for Q-switching and Pockels cells.

- Large Angular Acceptance and Low Walk-off Angle: Easier beam alignment and higher conversion efficiency.

- Stable Physical and Chemical Properties: High mechanical strength and environmental stability.

-

Lanthanum sputtering targets are crucial for creating thin films with specific electronic, optical, and catalytic properties, making them valuable in advanced technologies such as semiconductors, optics, superconductors, and energy storage systems. Despite its reactivity, lanthanum’s unique characteristics provide significant advantages in various high-tech industrial and scientific applications.

-

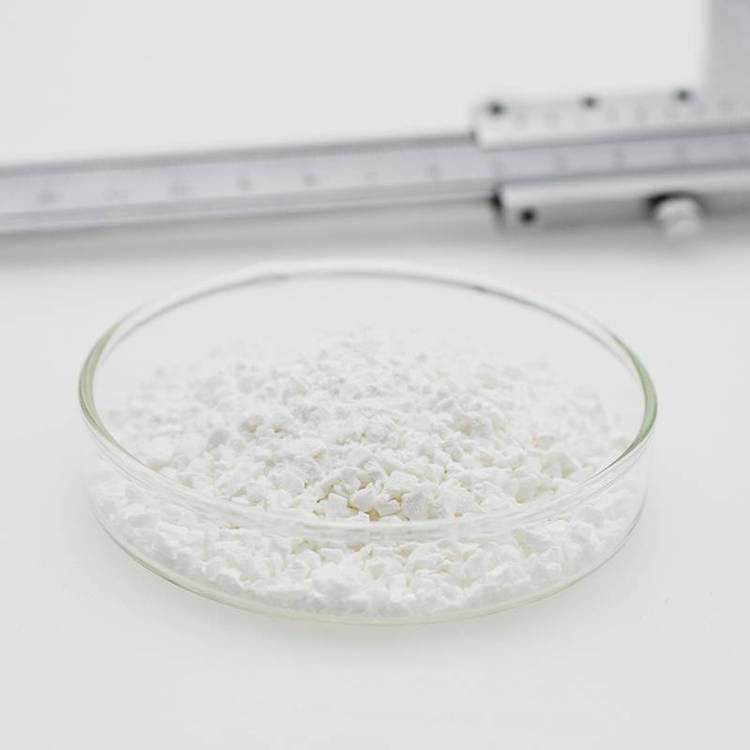

- High Refractive Index: La₂O₃ has one of the highest refractive indices among the oxides, making it highly suitable for optical applications where precise light manipulation is required.

- Excellent Dielectric Properties: It has a high dielectric constant, which is beneficial for use in electronic devices and capacitors.

- Infrared Transparency: La₂O₃ is transparent in the infrared spectrum, which makes it an ideal material for infrared optics and laser applications.

- High Purity: The high purity of La₂O₃ pellets ensures the production of high-quality thin films with minimal contamination.

-

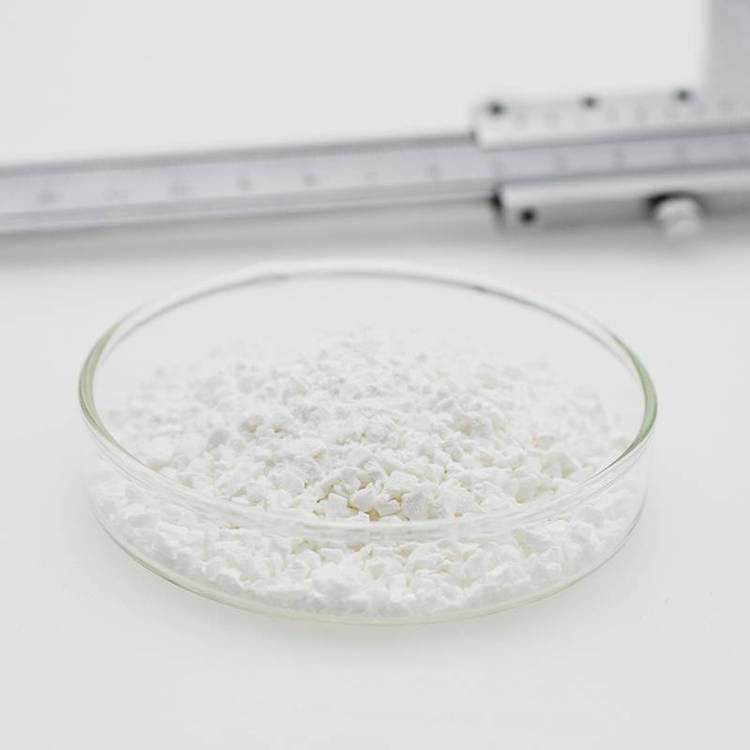

- High Purity: ≥99.9% purity, ensuring superior performance in critical applications.

- Optical Properties: Excellent refractive index and high transparency in the infrared spectrum, ideal for optical applications.

- Catalytic Properties: Highly effective as a catalyst in industrial processes such as petroleum refining and environmental protection.

- Chemical Stability: Chemically stable and resistant to high temperatures and oxidation, making it durable for high-performance applications.

- Versatile Applications: Suitable for use in a wide range of industries, from electronics and ceramics to environmental technologies.