Showing 301–312 of 678 results

-

- High Dielectric Constant: La₂O₃ exhibits a high dielectric constant, making it an excellent material for advanced electronic components, such as gate dielectrics in MOSFETs.

- High Refractive Index: Its high refractive index makes it ideal for enhancing optical properties in coatings for lenses, filters, and other precision optical devices.

- Thermal and Chemical Stability: La₂O₃ is highly stable under extreme temperatures and chemically resistant, making it suitable for high-performance applications.

- Catalytic Efficiency: Lanthanum oxide’s catalytic properties are leveraged in thin films used for environmental and energy applications.

-

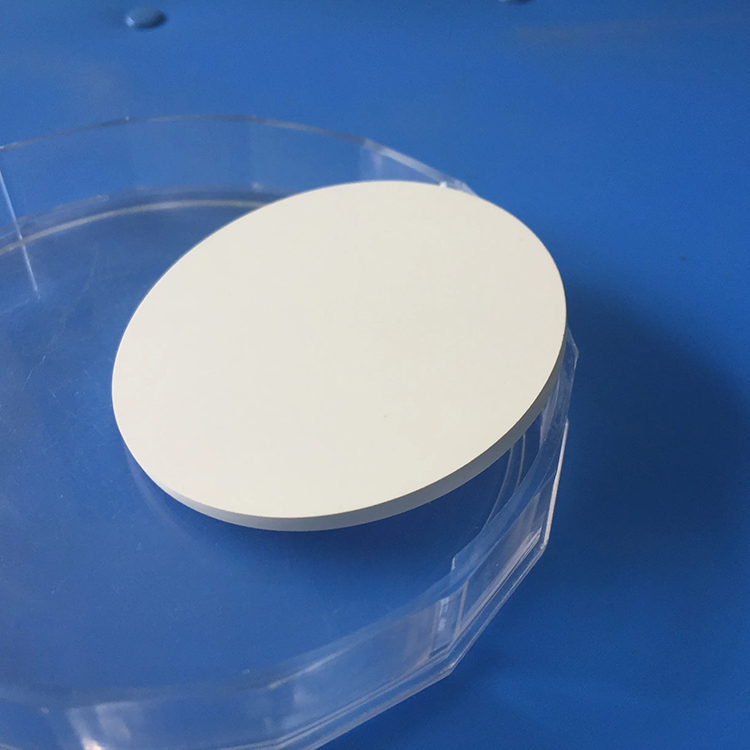

- High Dielectric Constant: LaAlO₃ has a high dielectric constant (k-value), which enhances its performance in capacitors and other high-k dielectric applications.

- Thermal Stability: LaAlO₃ exhibits excellent thermal stability, making it ideal for high-temperature processing and devices that operate in extreme environments.

- Structural Integrity: The perovskite structure of LaAlO₃ contributes to its high mechanical strength and chemical stability, ensuring long-lasting performance in demanding applications.

- Oxide Electronics: LaAlO₃ is widely used in complex oxide electronics due to its ability to form high-quality interfaces with other materials like SrTiO₃ and LaNiO₃.

-

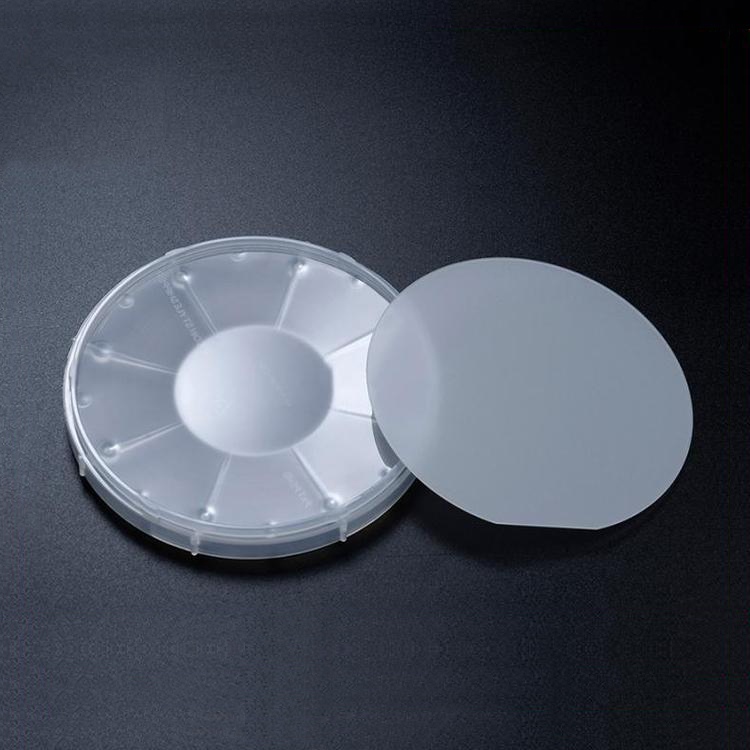

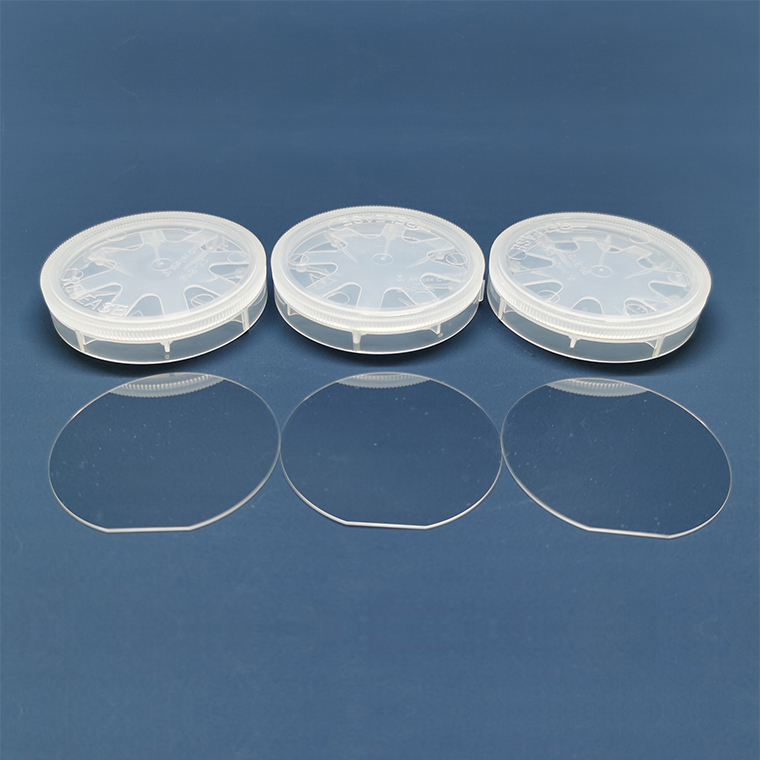

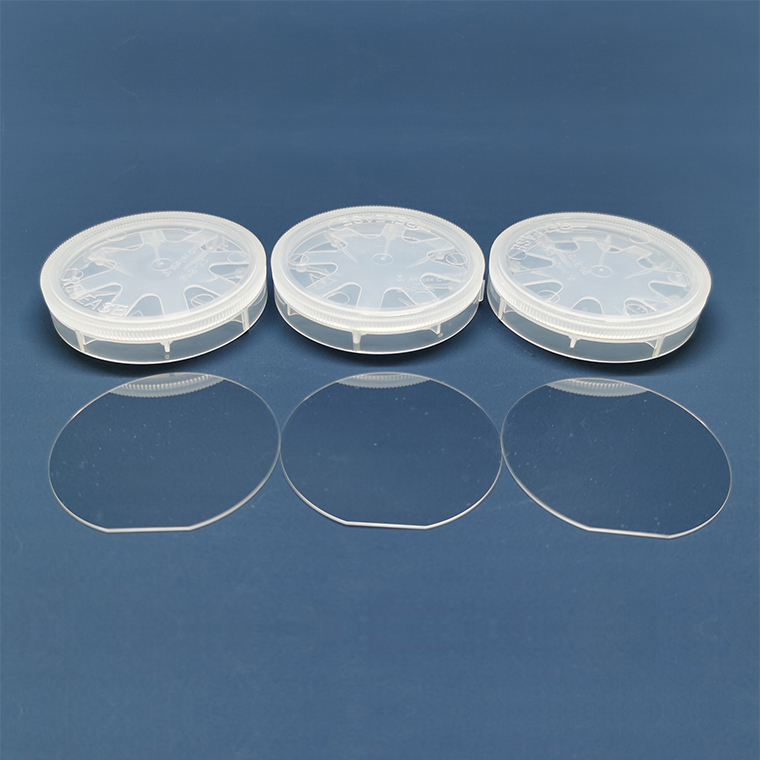

- Excellent Crystal Quality: Low dislocation density, high structural perfection.

- Ideal Lattice Match: Close lattice parameters with materials like YBCO, LSMO, PZT, and other perovskite oxides.

- High Thermal Stability: Suitable for high-temperature thin film deposition processes.

- High Dielectric Constant: Beneficial for microwave devices and tunable capacitors.

- Low Dielectric Loss: Ensures superior performance at high frequencies.

- Chemical Stability: Strong resistance to acids and bases.

- Atomically Smooth Surface: Achieved through advanced polishing and chemical etching processes.

-

- High Electron Emission Efficiency: Ideal for use in electron emitters.

- Low Work Function: Ensures efficient electron emission at lower temperatures.

- Thermal Stability: Maintains performance at high temperatures, making it suitable for high-power applications.

- Excellent Conductivity: Offers high electrical conductivity for advanced technological applications.

- Purity: Available in high-purity grades for sensitive applications.

-

- High Thermal Stability: Performs well in high-temperature environments.

- Superior Electrical Conductivity: Ideal for electronic and thermionic applications.

- Low Work Function: Enables efficient electron emission.

- Oxidation Resistance: Long-lasting performance under challenging conditions.

- Customizable Specifications: Tailored to meet specific application needs.

-

- Exceptional Ionic Conductivity: Enhances energy transfer in battery technologies.

- Stable and Durable: Chemically stable under a wide range of operating conditions.

- High Dielectric Constant: Ideal for electronic and capacitor applications.

- Customizable: Available in multiple sizes, shapes, and purity levels to meet specific application needs.

- Compatible: Works efficiently with various sputtering deposition systems.

-

- Mott Insulator Properties: LaTiO₃ exhibits insulating behavior despite having partially filled electronic bands, which makes it valuable in the study of Mott insulators and potential applications in quantum electronics.

- Perovskite Structure: Its perovskite crystal structure enables integration into other perovskite materials and systems, providing flexibility in multilayered thin-film devices.

- Electrical and Magnetic Properties: LaTiO₃ exhibits a combination of electrical and magnetic properties that are useful in advanced electronic devices.

- Optical Transparency: The material is transparent in certain spectral regions, making it suitable for use in optoelectronic devices.

-

- High Purity: ≥99.9% purity, ensuring optimal performance in sensitive applications.

- Fine Powder: Available in micro and nano particle sizes, providing enhanced reactivity and consistency.

- Versatile Applications: Ideal for use in lithium-ion batteries, ceramics, glass production, and pharmaceutical formulations.

- Environmental Compatibility: Non-toxic and suitable for eco-friendly applications in energy storage systems.

- Stable and Safe: Chemically stable under normal conditions and relatively safe for handling in industrial processes.

-

- High Purity: Guarantees low contamination for critical applications.

- Chemical Stability: Resistant to degradation, ensuring durable coatings.

- Superior Ionic Conductivity: Optimal for battery and energy storage films.

- Consistent Deposition: Ensures uniform and reliable thin-film performance.

- Customizable Dimensions: Adaptable to different sputtering systems and requirements.

-

$1.00 – $424.00

- High Stability: Li₄Ti₅O₁₂ has excellent chemical and structural stability, making it an ideal material for long-lasting energy storage devices.

- Low Volume Expansion: This material shows minimal expansion and contraction during charge/discharge cycles, improving battery longevity.

- Thermal Safety: Li₄Ti₅O₁₂ has a high thermal stability, reducing the risk of overheating in energy storage devices.

- Fast Charging Capability: The material is recognized for its fast charge/discharge properties, making it suitable for high-performance batteries.

-

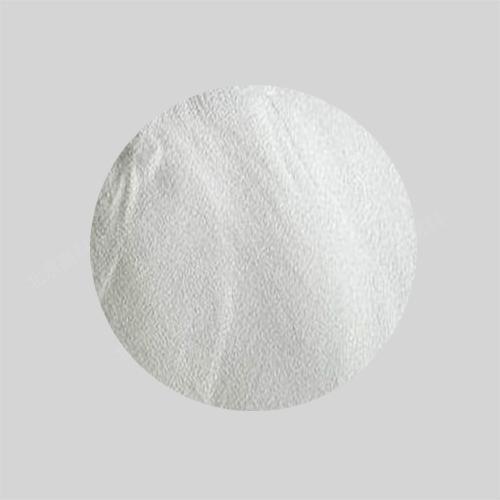

- High Thermal Stability: Excellent performance under high temperatures up to 1500°C.

- Wide Bandgap: Enables use in deep UV and high-power electronic applications.

- Superior Mechanical Strength: Resists thermal shock and mechanical stress.

- Excellent Lattice Match: Ideal substrate for GaN, AlN, ZnO, and other oxide semiconductor epitaxial growth.

- Low Dielectric Loss: Beneficial for microwave and RF device applications.

- Chemical Inertness: High resistance to acids, alkalis, and environmental degradation.

- Smooth, Defect-Free Surface: Essential for high-yield epitaxial growth and thin-film deposition.

-

- High Energy Density: LiCoO₂ has a high theoretical energy density, making it an ideal material for battery cathodes, especially in high-performance applications like electric vehicles and portable electronics.

- Stable Structure: The layered crystal structure of LiCoO₂ contributes to its stable electrochemical performance, which is crucial for the long-term operation of lithium-ion batteries.

- Excellent Cycling Performance: LiCoO₂ can undergo many charge and discharge cycles without significant degradation, ensuring reliable performance in rechargeable battery systems.

- Thin Film Deposition: LiCoO₂ sputtering targets allow for the precise deposition of thin films in applications requiring uniform coatings, such as in thin-film batteries and microelectronics.