Showing 313–324 of 678 results

-

- High Optical Transparency: LiF has high optical transparency in the UV, visible, and infrared regions, making it an excellent material for optical coatings and components.

- Wide Bandgap: LiF has a wide bandgap (~13.6 eV), which makes it an excellent insulating material in electronic and optoelectronic applications.

- Low Absorption: LiF thin films exhibit low absorption across a broad spectral range, making them ideal for applications where minimal light loss is required.

- Chemical Stability: LiF is chemically stable and resistant to moisture, which contributes to its durability in harsh environments and long-lasting performance in thin-film coatings.

- Insulating Properties: LiF has excellent insulating properties, which are beneficial for electronic and optoelectronic devices where electrical isolation is needed.

-

- High Purity: Ensures minimal impurities, delivering superior film quality.

- Thermal Stability: Provides consistent performance under varying conditions.

- Safety Profile: Stable chemistry reduces risks of thermal runaway.

- Customizable Dimensions: Tailored to fit a range of sputtering systems.

- Reliable Deposition: Delivers uniform and high-quality thin films.

-

$1.00 – $595.00

- High Electro-optic Coefficient: LiNbO₃ has a high electro-optic coefficient, enabling efficient modulation of light in waveguides, modulators, and telecommunications devices.

- Excellent Piezoelectric Properties: LiNbO₃’s strong piezoelectric response makes it ideal for use in SAW devices, sensors, and actuators, providing high sensitivity and control.

- Nonlinear Optical Capabilities: LiNbO₃ is widely used for frequency conversion and other nonlinear optical applications due to its strong nonlinear optical response.

- Ferroelectric Behavior: LiNbO₃’s ferroelectric properties are valuable in memory devices and data storage, enabling the development of non-volatile memory technologies.

- Stable and Durable Thin Films: LiNbO₃ thin films exhibit high thermal and chemical stability, making them suitable for use in demanding environments and high-performance applications.

-

- High purity (≥99.9%).

- Excellent electro-optical and piezoelectric properties.

- Stable chemical and thermal performance.

- Uniform size for consistent evaporation.

- Customizable pellet sizes and shapes.

-

- High Purity: Ensures minimal impurities for superior thin-film quality.

- Exceptional Piezoelectric Properties: Ideal for high-performance acoustic and vibrational devices.

- Stable Electro-Optic Behavior: Suitable for high-precision optical applications.

- Customizable Specifications: Tailored to meet unique system requirements.

- Durable and Reliable: Manufactured for consistent sputtering performance.

-

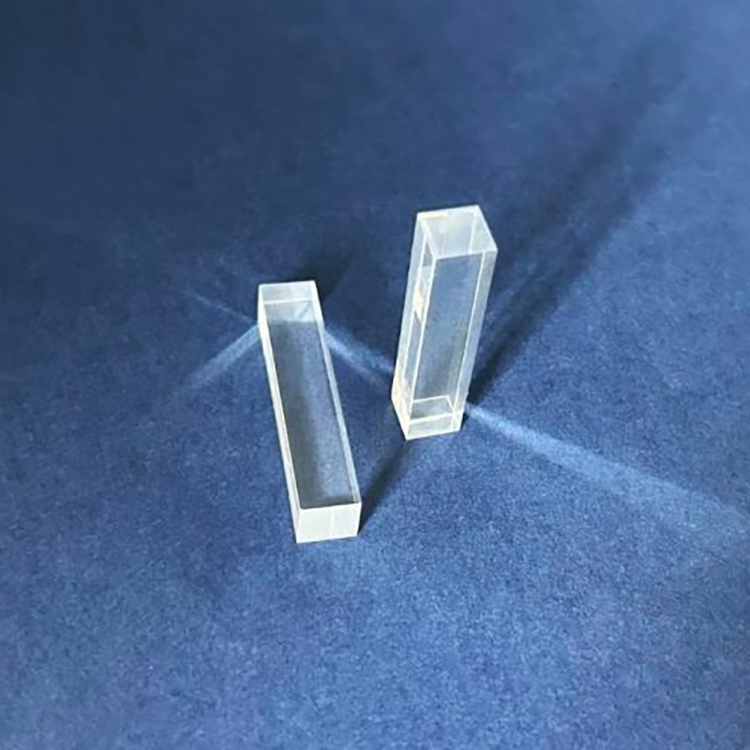

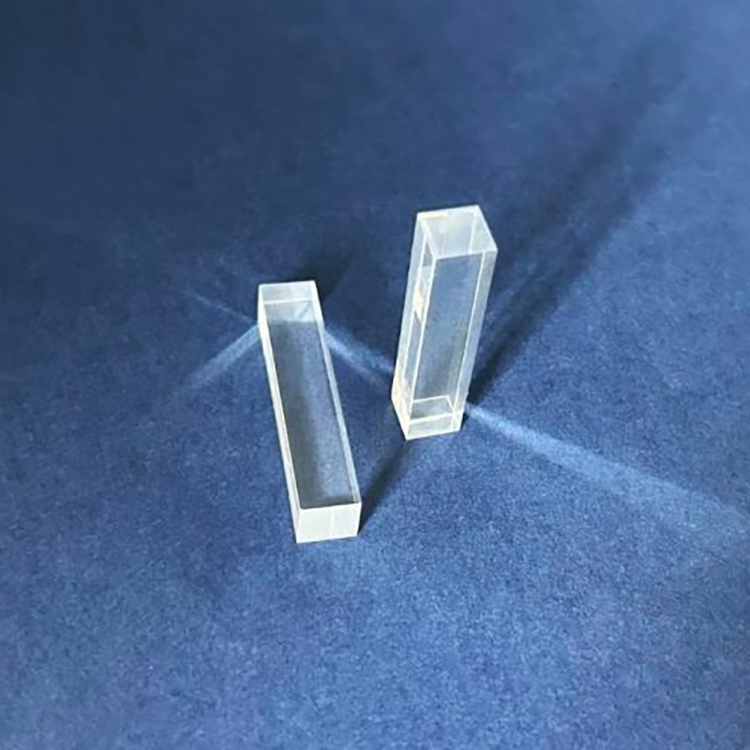

- Wide Transmission Range: Excellent optical transmission from 120 nm (VUV) to 6 μm (IR).

- Low Refractive Index: ~1.39 at 400 nm, advantageous for minimal Fresnel losses.

- Radiation Resistance: High durability against X-rays and high-energy particle irradiation.

- High Optical Homogeneity: Suitable for precision optics and laser systems.

- Good Mechanical Properties: Higher hardness compared to other VUV transparent materials like CaF₂.

- Low Birefringence: Enabling better performance in polarization-sensitive applications.

- Chemical Stability: Moderate chemical inertness; surface can be protected with appropriate coatings if needed.

-

- High Electro-optic Coefficient: Enables efficient light modulation

- Excellent Nonlinear Optical Properties: Ideal for frequency conversion processes

- Wide Transmission Range: Suitable for UV, visible, and infrared applications

- Strong Piezoelectric Response: Essential for SAW and MEMS devices

- Photorefractive Effect: Useful for holography and optical data storage

- Chemical and Thermal Stability: High reliability in demanding environments

- Availability of Stoichiometric and MgO-doped Variants: Reduces photorefractive damage and enhances performance in high-power lasers

- Precise Crystal Growth and Wafer Fabrication: Ensures high uniformity and low defect densities

-

- Wide Transparency Range: 160 nm to 2600 nm

- Broad Phase-Matching Capability: Suitable for SHG, THG, OPO, SFG, DFG across UV to IR

- High Damage Threshold: >2 GW/cm² for 1064 nm, 10 ns pulse

- Low Walk-Off Angle: Ideal for high-beam-quality laser systems

- High Nonlinear Coefficients: Enables efficient frequency conversion

- Excellent Optical Homogeneity: Δn < 10⁻⁶/cm

- Good Mechanical Hardness: Mohs hardness ~6

- Stable Physical and Chemical Properties: Resistant to humidity and environmental degradation

- Nonhygroscopic: No special humidity control required

-

- High Purity: Ensures consistent and reliable thin-film deposition.

- Superior Electrochemical Performance: Supports high energy density and stability.

- Customizable Options: Available in various sizes, shapes, and purity levels.

- Durable and Stable: Delivers reliable performance in demanding environments.

- Scalability: Suitable for both research-scale and industrial-scale applications.

-

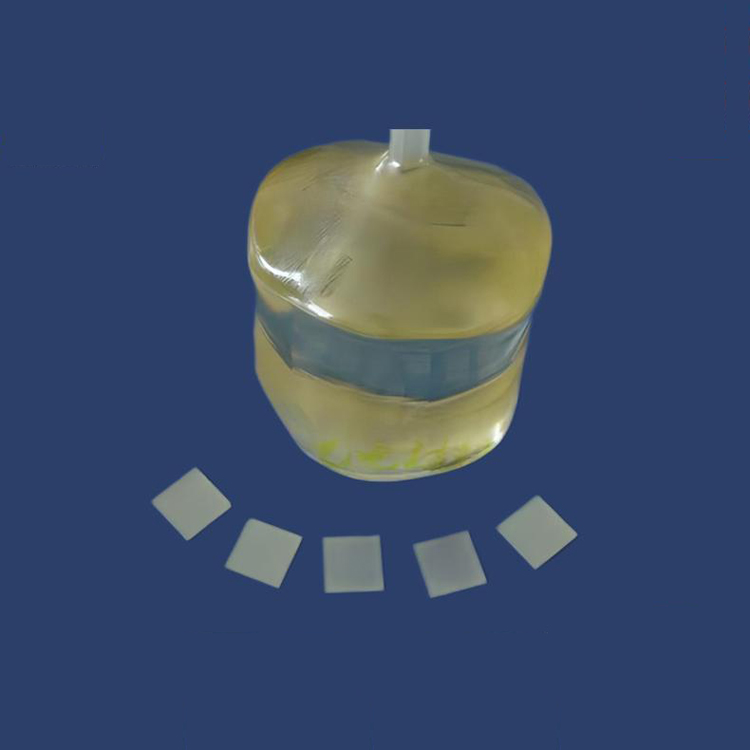

- Excellent Lattice Matching: Ideal match for many perovskite oxides such as YBCO, BST, and PZT

- High Thermal Stability: Maintains structural integrity under high temperatures

- Low Dielectric Loss: Suitable for microwave and dielectric applications

- High Crystallinity: Enables defect-free epitaxial film growth

- Good Mechanical Strength: Durable for various thin-film deposition processes

- Smooth Surface Finish: Atomic-level flatness for epitaxial growth

- High Chemical Stability: Resists degradation during processing

- Wide Application Range: Compatible with superconducting, ferroelectric, and oxide-based systems

-

- High Density: Lutetium is one of the densest rare-earth elements, providing superior durability in thin films.

- Optical and Catalytic Efficiency: Lutetium’s optical properties make it a valuable material for optical coatings, while its catalytic properties are utilized in industrial processes.

- High Purity: Lutetium pellets are available in high-purity forms, ensuring consistent film quality in evaporation processes.

- Thermal Stability: Lutetium films maintain stability at high temperatures, making them suitable for high-performance applications.

-

- High Density: Lutetium is one of the densest of the lanthanides, giving it unique properties for use in specialized materials and applications.

- Corrosion Resistance: Lutetium is resistant to oxidation and corrosion, making it durable in various environments.

- Radioisotope Lu-177: Lutetium-177, a radioactive isotope, is used in targeted radionuclide therapy (TRT), particularly for treating neuroendocrine tumors.

- Stable Catalyst: Lutetium is used as an efficient catalyst for cracking hydrocarbons in petroleum refining and polymerization reactions.

- Luminescent Properties: Lutetium compounds are employed in certain light-emitting applications due to their luminescence when excited by radiation.