Showing 325–336 of 678 results

-

- High Refractive Index: Lu2O3 has a high refractive index, making it ideal for use in optical coatings where precise control over light transmission and reflection is critical.

- Excellent Thermal Stability: Its high melting point and thermal conductivity make it suitable for high-temperature applications and vapor deposition processes.

- High Purity: Available in high-purity grades (≥ 99.9%) to ensure consistent film quality and performance in sensitive applications such as semiconductor manufacturing and optical device production.

- Transparency in the Visible and Infrared: Lutetium oxide provides excellent optical transparency across a broad wavelength range, from the visible to infrared (IR), enhancing its applicability in optical devices.

-

- High Purity: ≥99.9% purity, ensuring consistent performance in sensitive and high-tech applications.

- Excellent Thermal and Optical Properties: High melting point (around 2600°C), excellent thermal conductivity, and transparency to UV and visible light.

- Fine Powder: Available in various particle sizes to suit different processing needs, including nano and micron sizes.

- Stability: Chemically stable under high temperature and pressure conditions, making it suitable for demanding applications.

- Environmentally Friendly: Non-toxic and safe for industrial use with minimal environmental impact.

-

- Lightest Structural Metal: Exceptionally low density for weight-sensitive applications

- Excellent Specific Strength: High strength-to-weight ratio

- Anisotropic Mechanical Properties: Ideal for deformation and slip system studies

- High Ductility at Elevated Temperatures: Improved formability in warm/hot conditions

- Good Machinability: Easier to process compared to other metals

- High Thermal Conductivity: Facilitates efficient heat dissipation

- Superior Homogeneity: Enables reproducible experimental results

- Corrosion Sensitivity: Useful for corrosion research and protective coating studies

-

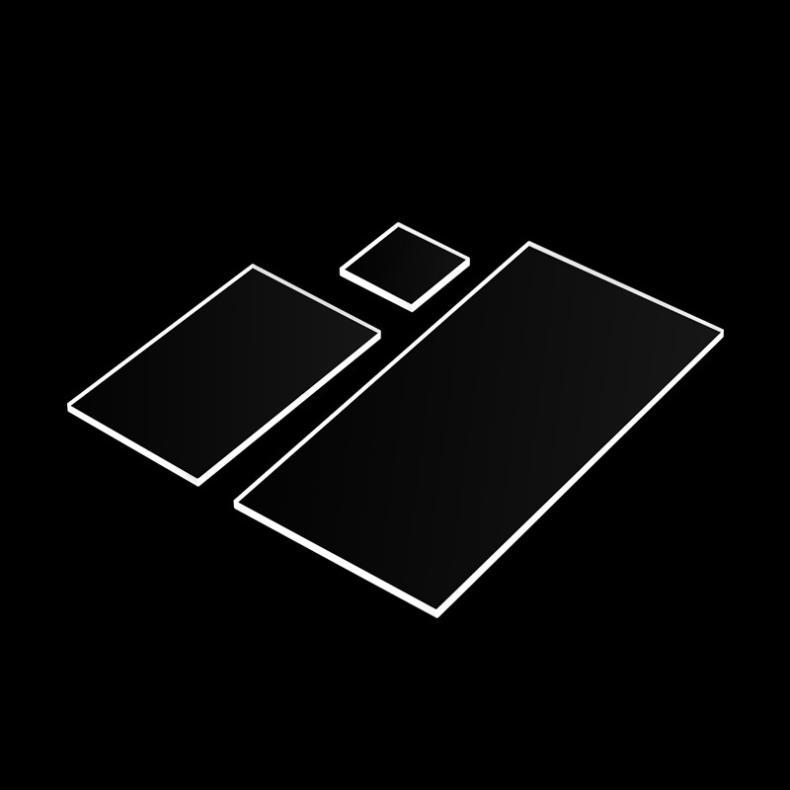

- Excellent Thermal Stability: Suitable for high-temperature processing (melting point ~2135°C)

- Wide Optical Transmission: From 200 nm (UV) to 5000 nm (Mid-IR)

- Superior Mechanical Strength: High hardness and fracture toughness

- Low Thermal Expansion: 8.5 × 10⁻⁶ /°C at 25°C

- High Chemical Resistance: Stable in both acidic and alkaline environments

- Low Dielectric Loss: Favorable for microwave and RF applications

- Surface Quality: Polished to atomic-level smoothness (Ra < 5 Å)

- High Purity: Low levels of impurities ensuring consistent and repeatable results

-

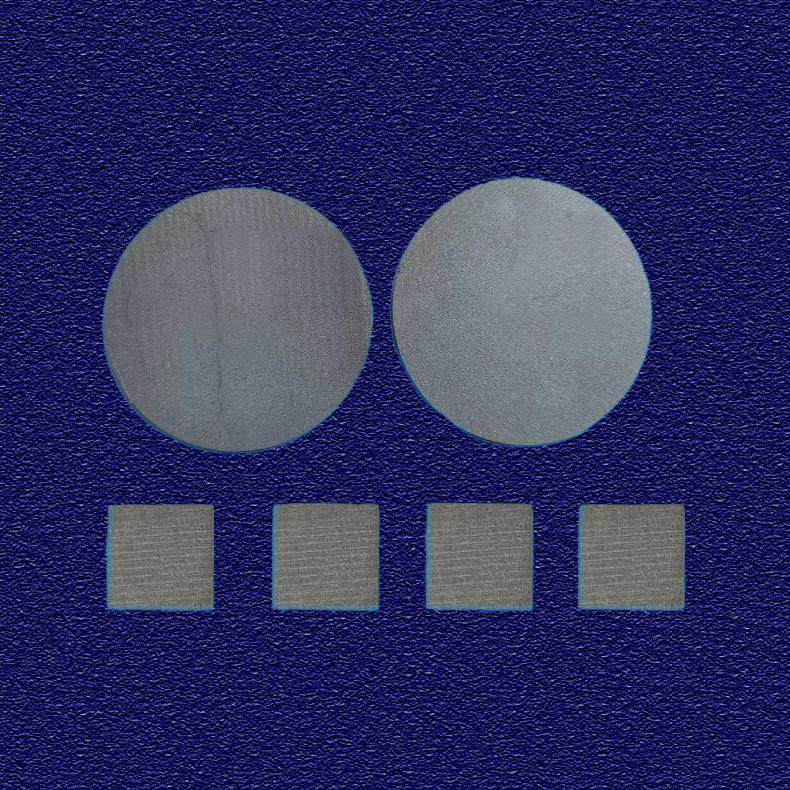

- Excellent lattice matching for oxide thin films

- Wide transparency from UV to IR regions (0.3μm–6μm)

- High thermal conductivity and melting point (2852°C)

- Chemically inert to most acids and alkalis

- Low dielectric constant (ε ≈ 9.65 at 1MHz)

-

$895.00

- High purity: 99.9% (3N) for consistent film composition

- Precise alloy ratio (1:1 at%) for uniform deposition

- Indium bonding + copper backing plate for efficient heat transfer

- Compatible with magnetron sputtering systems

- Supports stable deposition rates & low impurity levels

- Customizable sizes, thicknesses, and atomic ratios available

-

- High Purity: Magnesium pellets are available with high purity levels (99.9% or higher), ensuring the creation of thin films with minimal impurities.

- Lightweight: Magnesium is one of the lightest structural metals, offering the advantage of lightweight coatings in applications where weight savings are critical.

- Reactivity: Magnesium is highly reactive, making it ideal for creating compounds or alloys for specific functional coatings.

- Good Reflectivity: Magnesium provides good reflective properties, especially in the UV and visible spectrum, making it suitable for optical applications.

- Easy Deposition: Magnesium pellets evaporate easily at relatively low temperatures, making them convenient for deposition in vacuum systems.

-

- High Thermoelectric Efficiency: Magnesium Bismuth is recognized for its high Seebeck coefficient and low thermal conductivity, making it an efficient material for thermoelectric applications.

- Low-Temperature Thermoelectrics: Mg3Bi2 is particularly effective at lower temperatures, which makes it suitable for a wide range of thermoelectric devices that operate in ambient conditions.

- Customizable Film Properties: The thin films produced using Mg3Bi2 targets can be tailored in terms of thickness and crystallinity, allowing for optimization in various applications.

- Chemical Stability: Magnesium Bismuth films exhibit good stability, ensuring reliable performance over time in demanding environments.

-

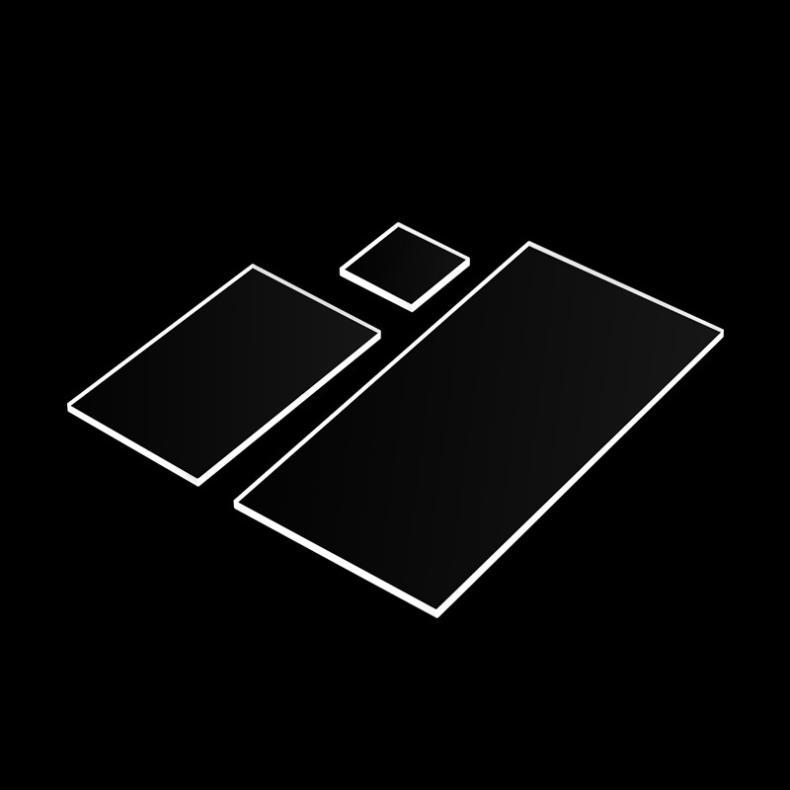

- Wide Transmission Range: Transmits from UV (~120 nm) to IR (~7 µm) wavelengths, making it versatile for a variety of optical applications.

- Low Refractive Index: MgF2 has a low refractive index (~1.38 at 550 nm), making it ideal for anti-reflective coatings.

- High Durability: Magnesium fluoride is resistant to mechanical wear and scratches, providing longevity to coated optical surfaces.

- Chemical Stability: It is chemically inert and highly resistant to most acids and alkalis, ensuring its stability in harsh environments.

- High Damage Threshold: MgF2-coated optics have high laser damage thresholds, making them suitable for high-power laser systems.

-

- Broad Transparency Range: MgF₂ has excellent transmission across UV, visible, and IR spectra, making it an ideal material for high-performance optical coatings.

- Low Refractive Index: The low refractive index of MgF₂ helps reduce light reflection, enabling its use in anti-reflective coatings for various optical applications.

- High Hardness and Durability: Magnesium Fluoride films are known for their hardness and resistance to scratching, making them suitable for protective coatings in high-durability environments.

- Chemical and Environmental Stability: MgF₂ coatings are chemically inert and stable under extreme temperature conditions, enhancing their use in both optical and electronic applications.

-

- Lightweight: Offers a lower density compared to other metals, making it suitable for applications where weight is a concern.

- Enhanced Strength: The combination of magnesium and manganese improves mechanical strength and durability.

- Corrosion Resistance: Provides good resistance to oxidation and corrosion, enhancing the longevity of components.

-

- High Dielectric Constant: MgO is known for its high dielectric constant, making it an effective insulating material for electronic applications.

- Optical Transparency: Exhibits excellent transparency across a wide spectral range, from UV to IR, making it suitable for optical applications.

- High Melting Point: With a melting point of approximately 2852°C, MgO can withstand high-temperature processing conditions, making it ideal for high-temperature coatings and insulation.

- Thermal Stability: Magnesium oxide is highly stable in a range of temperatures, providing durability in both deposition and application.

- Chemical Resistance: MgO is chemically inert, resistant to most acids and bases, making it suitable for protective layers in harsh environments.