Showing 481–492 of 678 results

-

- High Hardness: Si₃N₄ thin films are extremely hard and wear-resistant, making them ideal for applications in harsh mechanical environments.

- Excellent Thermal Stability: Si₃N₄ offers high thermal stability, ensuring reliability and performance in high-temperature applications, such as semiconductors and aerospace components.

- Low Thermal Expansion: Silicon Nitride exhibits low thermal expansion, contributing to its stability and performance under thermal stress.

- Chemical Resistance: Si₃N₄ is chemically inert and resists corrosion from most acids, bases, and chemical agents, which makes it suitable for protective coatings in chemically aggressive environments.

- Insulating Properties: Si₃N₄ films are used as dielectric materials due to their excellent electrical insulating properties, ensuring their use in semiconductor and electronic applications.

-

- High Hardness: SiC is one of the hardest materials available, making it ideal for protective coatings and abrasive applications.

- High Thermal Conductivity: SiC efficiently dissipates heat, making it suitable for high-temperature coatings in optical and electronic devices.

- Chemical Stability: SiC is highly resistant to corrosion and oxidation, which is beneficial for coatings in harsh environments.

- Wide Bandgap: In electronics, SiC thin films enable higher efficiency in power management and thermal resistance.

-

- Exceptional Hardness: Mohs hardness of 9.2, ideal for abrasives and wear-resistant applications.

- Thermal Resistance: Stable in high-temperature environments up to 2,700°C.

- High Thermal Conductivity: Efficient heat transfer for thermal management.

- Chemical Inertness: Resistant to corrosion and oxidation in harsh conditions.

- Customizable Particle Sizes: Nano and micron sizes for specialized applications.

- Eco-friendly: Minimal environmental impact during use.

-

- Exceptional Hardness: Ideal for durable, wear-resistant coatings.

- High Thermal Stability: Performs well under extreme temperatures.

- Wide Bandgap Properties: Suitable for high-power and high-frequency applications.

- Chemical Resistance: Resilient to corrosive environments.

- Customizable Configurations: Available in various sizes, purities, and bonding options.

-

- Wide bandgap (3.2 eV for 4H-SiC)

- High thermal conductivity (~4.9 W/cm·K)

- Excellent chemical resistance

- High voltage breakdown strength

- Radiation hardness

- Suitable for GaN-on-SiC and epitaxial SiC device growth

-

$46.00 – $200.00

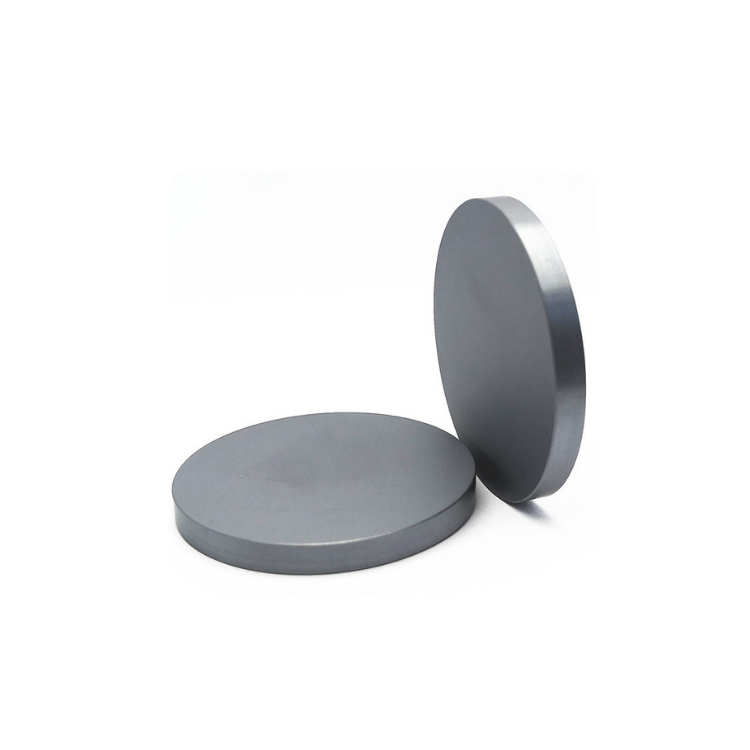

- Ultra-high purity 5N (99.999%) for superior thin-film quality and minimal contamination.

- Stable electrical properties due to controlled N-type doping.

- Excellent sputtering performance with uniform deposition and low particle generation.

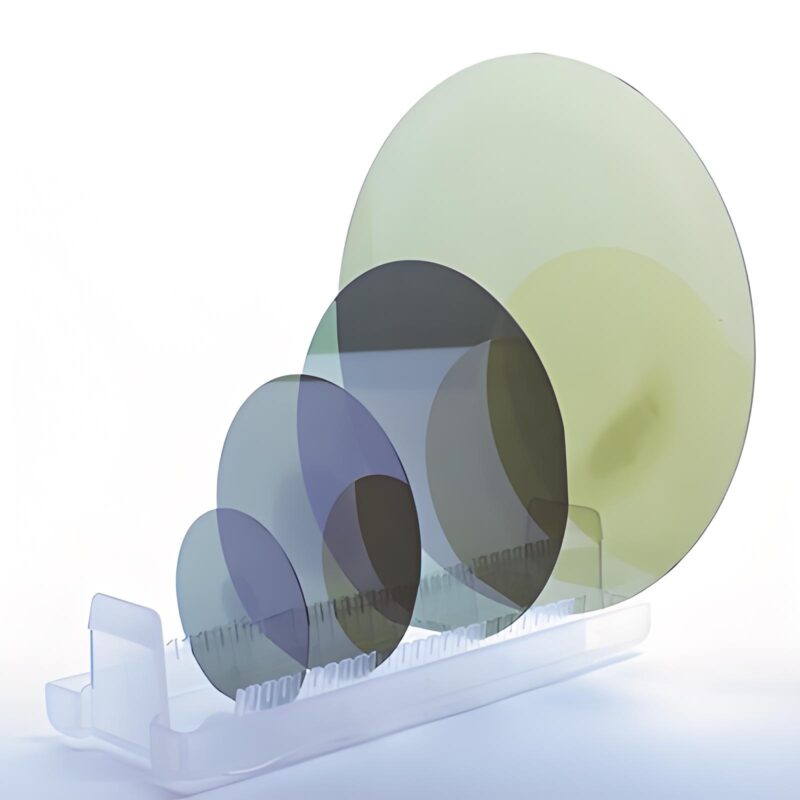

- Available in multiple diameters for different PVD systems.

- Customizable in purity, doping type, diameter, thickness, and bonding options.

-

$46.00 – $200.00

- Ultra-high purity 5N Silicon ensures extremely low impurity levels and superior thin-film quality.

- Stable p-type electrical conductivity ideal for semiconductor and solar applications.

- Excellent sputtering uniformity with minimal particle generation.

- Multiple standard diameters in stock for fast order fulfillment.

- Fully customizable target dimensions, purity, and doping concentration.

-

- High Purity: SiO pellets are typically manufactured with a purity of 99.9% or higher to ensure high-quality film deposition.

- Transparency in UV and Visible Range: SiO has good transmission properties in both the UV and visible light spectrum, making it suitable for optical applications.

- Hard and Durable Coating: Coatings formed from SiO are known for their hardness and durability, providing a protective layer for sensitive optical and electronic devices.

- Excellent Adhesion: SiO films exhibit strong adhesion to substrates, which is crucial for long-lasting coatings.

-

- High Purity: ≥99.5% for reliable performance in critical applications.

- Excellent Optical Properties: Ideal for thin-film optical coatings.

- Thermal Stability: Performs well in high-temperature environments.

- Versatile Particle Sizes: Available in nano and micron scales.

- Low Oxygen Deficiency: Ensures consistency in applications.

- Energy Storage Compatibility: Suitable for advanced battery systems.

-

- High Purity: Ensures superior film quality and consistent performance.

- Wide Optical Transparency: Suitable for coatings across UV, visible, and IR ranges.

- Stable and Durable: High thermal and chemical stability for demanding processes.

- Customizable Options: Available in various sizes, purities, and configurations.

-

- High Transparency: SiO2 is transparent across a wide spectral range, from UV to IR, making it ideal for optical applications.

- Excellent Insulating Properties: With high dielectric strength and low electrical conductivity, SiO2 is a perfect insulator for microelectronics and semiconductor applications.

- High Melting Point: SiO2 has a melting point of approximately 1,713°C, making it suitable for high-temperature deposition processes.

- Chemical Stability: SiO2 is highly resistant to most acids, bases, and solvents, offering long-lasting protective coatings.

- Mechanical Strength: It provides excellent hardness and durability, ensuring the stability and longevity of thin films.

-

- Excellent Insulator: SiO₂ has a high dielectric strength, making it a perfect insulating material for electronic devices and integrated circuits.

- High Optical Transparency: SiO₂ is highly transparent in the UV, visible, and near-IR regions, making it suitable for optical coatings and protective layers.

- Chemical Stability: SiO₂ exhibits strong chemical resistance, ensuring that deposited films are durable and stable under harsh environmental conditions.

- Thermal Stability: Silicon Dioxide can withstand high temperatures, making it reliable for use in applications that involve thermal stress.

- Hardness: SiO₂ provides a protective layer that is scratch-resistant and durable, making it ideal for surface coatings.