Showing 529–540 of 678 results

-

- High Corrosion Resistance: Tantalum provides superior protection against corrosion, especially in acidic and high-temperature environments.

- High Melting Point: Tantalum has a melting point of 3017°C, making it suitable for high-temperature applications.

- Excellent Adhesion: Tantalum adheres well to a variety of substrates, ensuring reliable and durable coatings.

- Biocompatibility: Tantalum is biocompatible and non-toxic, making it ideal for use in medical and dental applications.

- High Purity: Available in high-purity forms (≥ 99.95%) to ensure clean deposition with minimal impurities.

-

- High Melting Point: Melts at approximately 3,020°C, making it suitable for high-temperature applications.

- Corrosion Resistance: Inert to most acids and chemicals, ensuring durability in harsh environments.

- Biocompatibility: Non-toxic and suitable for medical implants.

- Excellent Conductivity: High electrical and thermal conductivity for advanced electronic applications.

- Customizable Particle Sizes: Available in various sizes to meet specific industrial needs.

-

- High Purity: Ensures contamination-free thin films for critical applications.

- Corrosion Resistance: Withstands harsh chemical environments.

- High Melting Point: Stable under extreme thermal conditions.

- Superior Electrical Conductivity: Suitable for advanced electronic devices.

- Customizable Options: Adaptable to specific design and operational requirements.

-

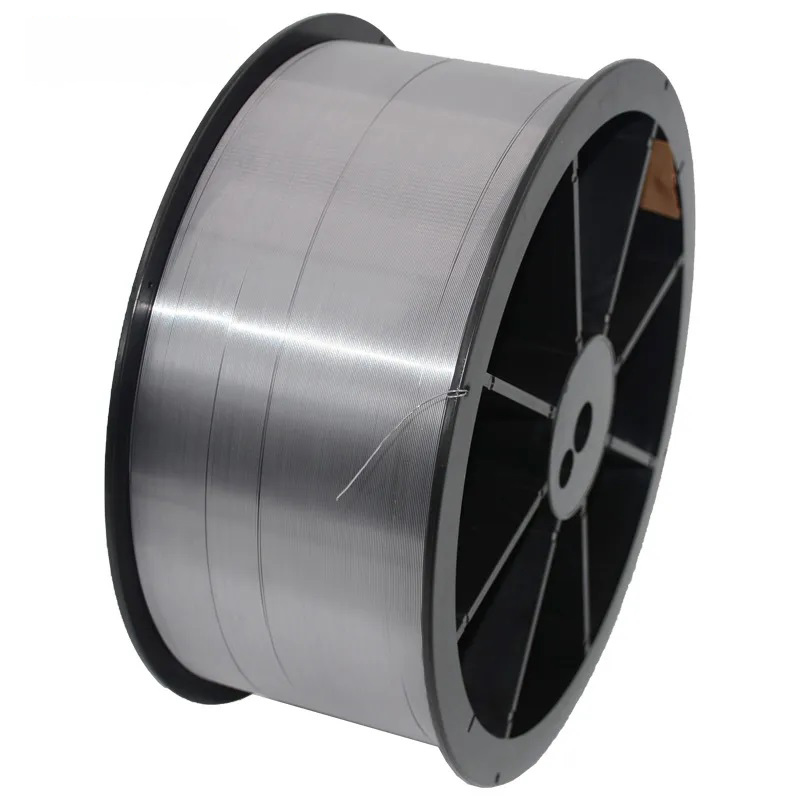

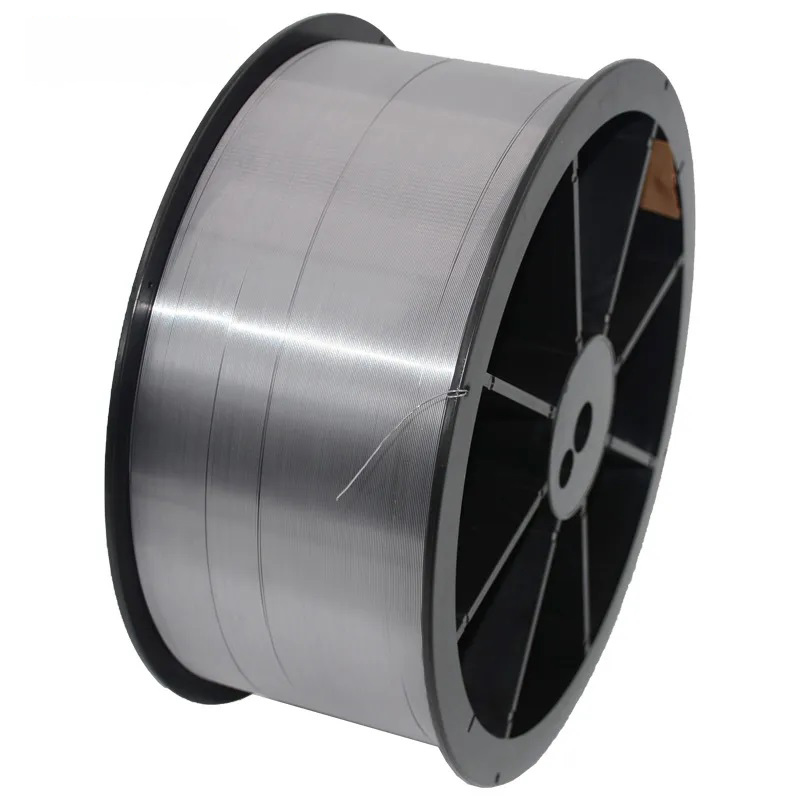

- High Melting Point: Tantalum has a melting point of approximately 3,020°C (5,468°F), which makes it an excellent material for high-temperature applications. This high melting point ensures that tantalum wires can perform effectively in environments where other materials would degrade or melt.

- Excellent Corrosion Resistance: One of the most remarkable properties of tantalum wires is their exceptional resistance to corrosion. Tantalum forms a protective oxide layer on its surface, which prevents corrosion even in highly acidic or alkaline environments. This makes tantalum wires ideal for use in the chemical industry and in environments where exposure to corrosive substances is common.

- Biocompatibility: Tantalum is biocompatible, meaning it does not cause any harm or rejection when implanted into the human body. This property makes tantalum wires ideal for use in medical applications such as implants, surgical devices, and electrodes.

- High Strength and Ductility: Despite its high melting point, tantalum wires maintain high mechanical strength and are highly ductile. This makes them easy to work with in manufacturing processes like wire drawing, while still providing durability under mechanical stress.

- Electrical Conductivity: Tantalum wires have good electrical conductivity, which makes them suitable for use in capacitors, resistors, and other electronic components that require stable and reliable performance.

- Thermal Stability: Tantalum wires maintain stability across a broad range of temperatures, from cryogenic levels to extremely high temperatures. This makes them ideal for applications that demand excellent thermal properties.

-

- High Strength: TA15 powder provides superior mechanical strength, ensuring durability in high-stress environments.

- Excellent High-Temperature Resistance: With excellent thermal stability, it performs well in extreme temperature conditions.

- Superior Fatigue Resistance: Offers excellent resistance to fatigue, making it suitable for dynamic and cyclic loading applications.

- Corrosion Resistance: TA15 exhibits excellent corrosion resistance, especially in harsh environments such as marine and chemical industries.

- Weldability: The alloy offers good weldability, ensuring high-quality joins in critical structural components.

- Biocompatibility: Safe for medical applications, ensuring no harmful reactions with the body.

-

- High Refractive Index: With a refractive index of around 2.1, Ta₂O₅ is ideal for multilayer coatings in optics, where light manipulation and reflection control are critical.

- Excellent Dielectric Properties: Ta₂O₅ offers a high dielectric constant, making it an effective insulator in capacitors and semiconductors.

- Wide Bandgap: Ta₂O₅ has a wide bandgap (~4 eV), which contributes to its transparency in the visible and NIR range and its low electrical conductivity.

- Thermal Stability: Ta₂O₅ exhibits excellent thermal stability, making it suitable for high-temperature processes and applications.

- Chemical Resistance: It is resistant to most acids and chemicals, ensuring longevity in harsh environments.

-

- High Purity: ≥99.9% purity, ensuring superior performance and reliability in sensitive applications.

- Dielectric Properties: High dielectric constant, making it ideal for capacitor applications and thin film deposition.

- Thermal Stability: Excellent stability under high temperatures, ensuring durability in harsh environments.

- Optical Properties: High refractive index, suitable for use in optical coatings and thin films.

- Fine Powder: Available in various particle sizes to meet different application needs, including nano and micron sizes.

- Chemical Stability: Highly resistant to corrosion, oxidation, and degradation, making it suitable for long-term use in demanding environments.

-

- High Dielectric Constant: Ta₂O₅ films exhibit a high dielectric constant, making them ideal for use in capacitors and semiconductor devices requiring high electrical insulation.

- Chemical and Thermal Stability: Ta₂O₅ provides excellent resistance to chemical attack and can withstand high temperatures, making it suitable for applications in harsh environments.

- Optical Transparency: Ta₂O₅ is transparent over a wide range of wavelengths, which makes it an excellent material for optical coatings that require high refractive index and low absorption.

- High Refractive Index: The high refractive index of Ta₂O₅ makes it ideal for optical multilayer coatings used in anti-reflective applications and optical filters.

- Durability: Ta₂O₅ films are known for their mechanical strength and durability, providing a robust protective layer in various high-performance applications.

-

- Exceptional Hardness: Provides excellent wear resistance in demanding conditions.

- High Thermal Conductivity: Ensures superior performance in high-temperature applications.

- Oxidation Resistance: Maintains stability in oxidative environments.

- Chemical Stability: Resistant to chemical degradation and corrosion.

- Versatility: Suitable for various industrial and scientific applications.

-

- Extreme Hardness: TaC coatings provide excellent hardness, making them ideal for cutting tools, wear-resistant coatings, and surfaces exposed to high friction.

- High Melting Point: With a melting point exceeding 3880°C, TaC is one of the most heat-resistant materials, suitable for high-temperature applications in aerospace and industrial processes.

- Corrosion Resistance: TaC films offer robust resistance to chemicals, making them ideal for protective coatings in chemically aggressive environments.

- Electrical Conductivity: TaC has good electrical conductivity, which is advantageous in certain electronic and semiconductor applications.

- Oxidation Resistance: The oxidation resistance of TaC enhances its performance in environments where exposure to high temperatures and reactive gases is common.

-

- Excellent Diffusion Barrier: TaN films provide an effective barrier against the diffusion of metals, such as copper, making them crucial for semiconductor devices.

- High Electrical Resistivity: TaN has a relatively high electrical resistivity, which makes it suitable for thin-film resistors and other resistive applications.

- Chemical and Thermal Stability: Tantalum Nitride exhibits excellent stability in extreme chemical and thermal environments, ensuring long-lasting performance in harsh conditions.

- Hardness and Wear Resistance: TaN films offer superior hardness and wear resistance, making them ideal for protective coatings in demanding industrial applications.

- Corrosion Resistance: TaN is resistant to corrosion, making it suitable for use in environments where exposure to chemicals or moisture is a concern.

-

- High Melting Point: With a melting point of 2996°C (5425°F), tantalum boats can operate in extreme high-temperature environments.

- Excellent Thermal Conductivity: Facilitates efficient heat distribution, ensuring uniform material evaporation.

- Corrosion Resistance: Highly resistant to chemical attack, especially from acids like hydrochloric and sulfuric acid.

- Durability: Exceptional mechanical strength and resistance to thermal shock, ensuring a long service life.

- Purity: Manufactured with high-purity tantalum to minimize contamination during evaporation processes.