Showing 85–96 of 678 results

-

- Multiferroic Properties: BiFeO₃ demonstrates both ferroelectric and antiferromagnetic properties, making it ideal for multifunctional devices.

- Room Temperature Functionality: One of the few multiferroic materials that operates effectively at room temperature, allowing for broader application in consumer electronics and industrial devices.

- Photovoltaic Effects: BiFeO₃ can be used to create thin films that convert light into electricity, opening avenues for energy harvesting and improving photovoltaic technologies.

- Customizable: The size, shape, and purity of BiFeO₃ sputtering targets can be tailored to meet specific requirements for various deposition techniques.

-

- Low Melting Point: Excellent for low-temperature soldering and thermal interface materials.

- Thermoelectric Properties: Exhibits promising performance in energy harvesting systems.

- Customizable Particle Size: Available in various sizes tailored to application needs.

- High Purity: Ensures reliable performance in precision applications.

- Environmentally Friendly: Contains no lead, making it suitable for eco-friendly applications.

-

- High Purity: BiSb pellets are typically available in high purity (99.9% or higher), ensuring the production of high-quality thin films free from contaminants.

- Thermoelectric Efficiency: The combination of Bismuth and Antimony provides exceptional thermoelectric properties, which is crucial for enhancing energy conversion efficiency in thin films.

- Uniform Evaporation: The spherical or irregular shape of the pellets allows for even melting and vaporization during the evaporation process, resulting in uniform deposition on substrates.

- Low Melting Point: BiSb alloys have a relatively low melting point, making them easier to handle in evaporation systems without the need for extreme temperatures.

-

- Excellent Thermoelectric Performance: BiSbTe is known for its high thermoelectric efficiency, which makes it ideal for thermoelectric cooling and energy conversion applications.

- Wide Temperature Range: BiSbTe thin films perform effectively across a broad range of temperatures, particularly between 200 K and 400 K, making them suitable for various environmental conditions.

- Customizable Compositions: The composition of BiSbTe sputtering targets can be adjusted by varying the ratio of bismuth, antimony, and tellurium to meet specific thermoelectric performance requirements.

- High Purity: BiSbTe sputtering targets are available in high-purity grades to ensure the highest quality thin films for critical applications in energy harvesting and temperature regulation.

- Stable & Durable: Bismuth Antimony Telluride thin films exhibit excellent stability, long-term durability, and resistance to degradation under prolonged thermal cycling.

-

- High Purity: ≥ 99.9% purity ensures high-quality thin films with precise optical and magnetic properties.

- Superior Magneto-Optical Performance: Provides excellent Faraday rotation and low optical loss.

- Stable Composition: Chemically stable and reliable for prolonged usage.

- Customizability: Available in various shapes, sizes, and thicknesses to fit specific sputtering systems.

- Compatibility: Suitable for both RF and DC magnetron sputtering methods.

-

- High Purity: Available in purities up to 99.999% for optimal film quality.

- Superior Deposition Uniformity: Enables precise and consistent thin-film formation.

- Thermal Stability: Performs well under high-temperature deposition conditions.

- Versatile Compatibility: Suitable for various sputtering systems, including DC and RF setups.

-

- High Electro-optic and Photorefractive Properties: Suitable for real-time holography and optical data processing.

- Cubic Crystal Structure: Isotropic optical properties, facilitating easier device integration.

- High Photoconductivity: Enhances photorefractive response and device efficiency.

- Broad Transparency Range: From ~450 nm to 7000 nm.

- High Optical Damage Threshold: Suitable for high-intensity light exposure.

- Excellent Thermal and Chemical Stability: Reliable under varied operating conditions.

-

- High Purity: Offers high purity to ensure the quality of thin films and optimal device performance.

- Excellent Thermoelectric Properties: Ideal for thermoelectric applications where high efficiency is crucial.

- Uniform Deposition: Provides uniform and stable sputtering, ensuring consistent thin film quality.

- Thermal Stability: Excellent resistance to heat and thermal cycling, making it suitable for high-temperature applications.

-

- High Thermal Conductivity: Boron nitride exhibits excellent thermal conductivity, which helps in evenly distributing heat within the crucible, ensuring uniform melting and preventing hot spots in high-temperature applications.

- High-Temperature Resistance: BN crucibles can withstand temperatures up to 3000°C in an inert atmosphere, making them ideal for high-temperature processes like metal melting, sintering, and crystal growth.

- Chemical Inertness: BN crucibles are highly resistant to chemical corrosion, including resistance to molten metals, acids, and alkalis, making them ideal for use in aggressive chemical environments.

- Low Thermal Expansion: Boron nitride has a low coefficient of thermal expansion, which minimizes the risk of cracking and warping under thermal stress and temperature fluctuations.

- Electrical Insulation: BN possesses excellent electrical insulation properties, which can be beneficial in applications where electrical conductivity must be minimized.

- Non-Toxic and Environmentally Friendly: Unlike some other high-performance materials, boron nitride is non-toxic and environmentally safe, making it a preferred choice for many industries.

-

- High Thermal Conductivity: Excellent ability to dissipate heat, ideal for high-temperature applications.

- Electrical Insulation: Acts as an efficient insulator while maintaining high thermal conductivity.

- Chemical Stability: Resistant to chemical corrosion, oxidation, and high-temperature degradation.

- Lubrication Properties: Provides natural lubrication in extreme environments, reducing friction and wear.

- Customizable Particle Size: Available in various sizes, tailored for specific applications.

-

- High Thermal Conductivity: Excellent heat dissipation properties.

- Electrical Insulation: Exceptional dielectric strength, ideal for electronic applications.

- Chemical Inertness: Resistant to oxidation and most chemicals.

- High Purity: Available with ≥99% purity for consistent and reliable performance.

- Lubricating Properties: Superior lubricity, even at high temperatures.

- Customizable Particle Sizes: Nano (<100 nm) and micro (1–50 µm) options available or customized.

-

- High Thermal Conductivity: BN targets are ideal for applications requiring effective heat management.

- Electrical Insulation: Provides excellent dielectric properties, essential for insulating layers in various electronic devices.

- Chemical Inertness: Highly resistant to most chemicals, ensuring long-term durability in aggressive environments.

- Easy to Sputter: BN sputtering targets have excellent sputtering properties, ensuring consistent and uniform deposition.

- High Purity: Available in high-purity grades for precision applications.

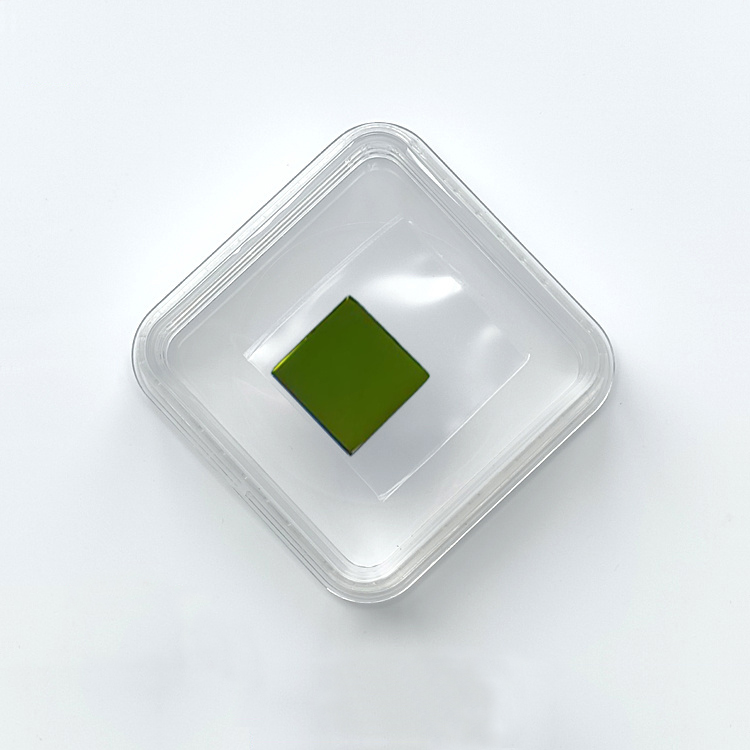

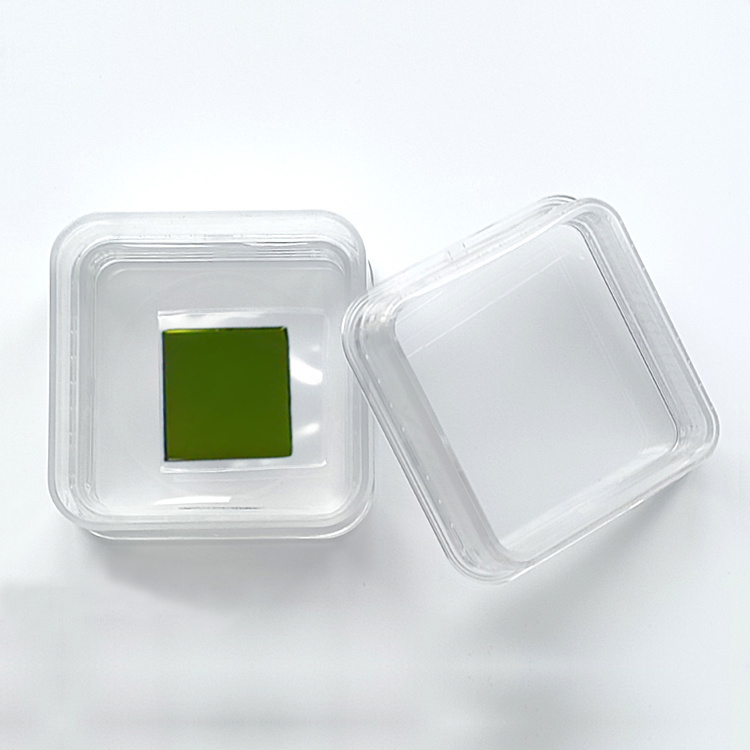

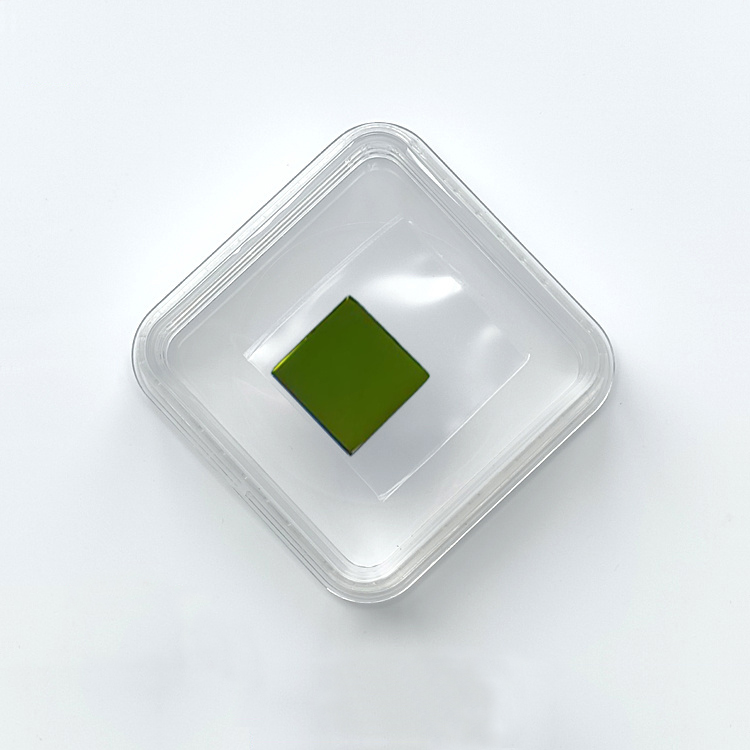

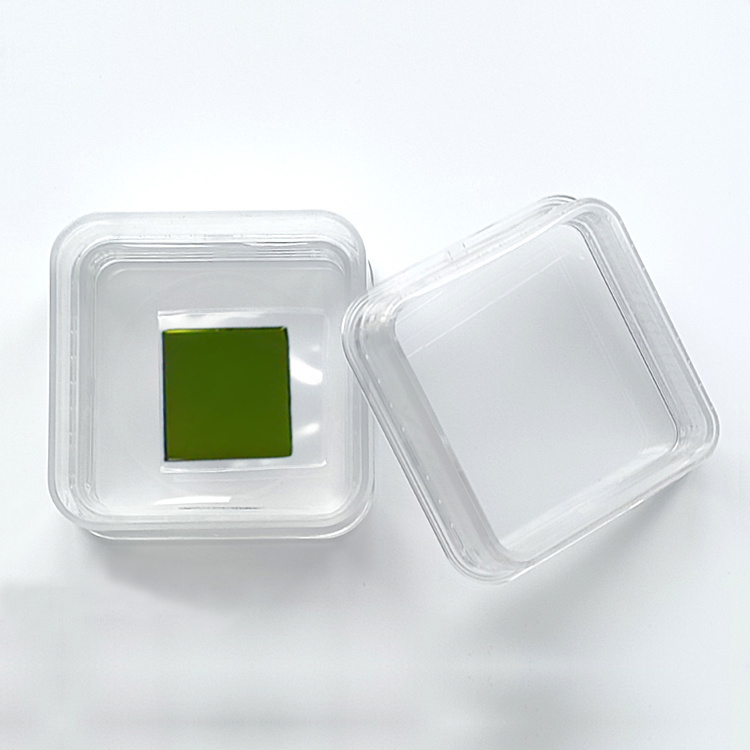

ZnO Single Crystal Substrate , 10×10×0.5 mm, Single-Side Polished (O-Face Polished)

ZnO Single Crystal Substrate , 10×10×0.5 mm, Single-Side Polished (O-Face Polished)