Showing 97–108 of 252 results

-

- High Purity: Ensures minimal contamination during deposition processes.

- Excellent Infrared Performance: Optimal for devices requiring sensitivity in the infrared spectrum.

- Uniform Film Deposition: Supports consistent and reliable thin-film production.

- Customizable Options: Tailored shapes, sizes, and purity levels to meet specific project requirements.

-

- High Purity: Iridium sputtering targets are available in ultra-high purity (up to 99.99%) to ensure the deposition of superior thin films for sensitive electronics and optical components.

- Thermal Stability: Iridium’s high melting point (~2446°C) makes it ideal for thin films that must withstand extreme heat in aerospace, semiconductor, and other high-temperature environments.

- Corrosion Resistance: Iridium is one of the most corrosion-resistant metals, ensuring long-lasting films in harsh chemical environments.

- Electrical Conductivity: Iridium thin films offer excellent electrical conductivity, making them essential for electronic applications requiring efficient current flow.

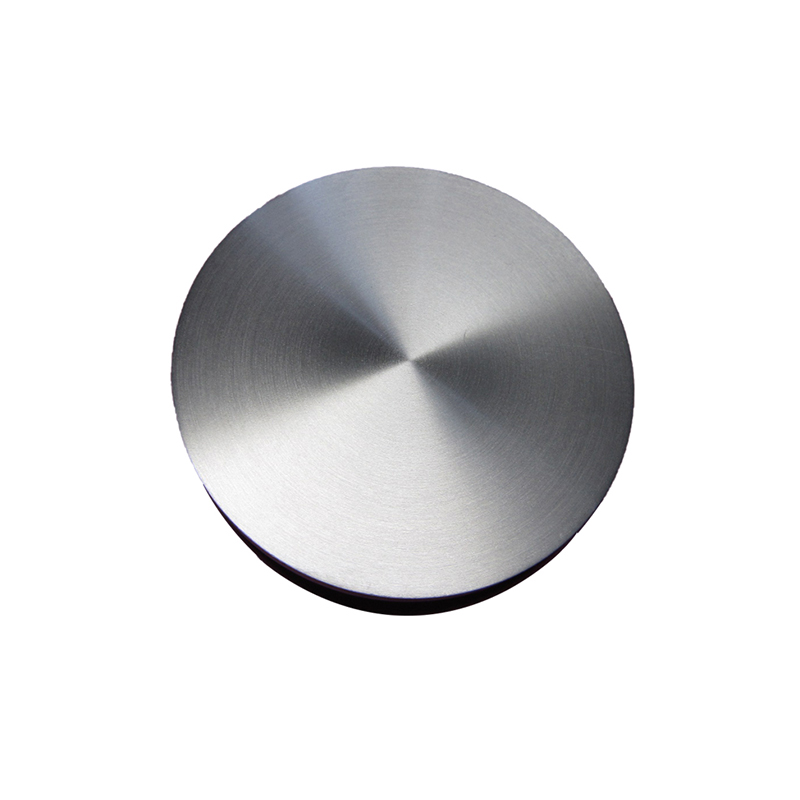

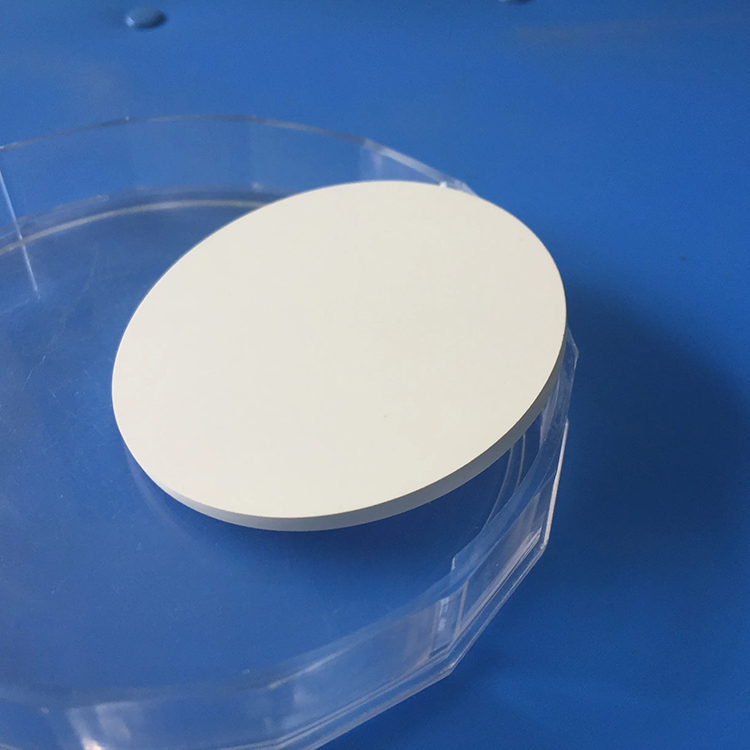

- Customizable Size and Shape: Available in various forms, including discs, plates, and custom geometries, to fit different PVD systems.

-

- Antiferromagnetic Properties: IrMn alloy thin films exhibit strong antiferromagnetic behavior, which is essential for magnetic pinning in spintronic devices and memory storage.

- High Corrosion Resistance: Iridium provides excellent corrosion resistance, ensuring the durability and longevity of the deposited thin films, even in harsh environments.

- Thermal Stability: IrMn alloy films are thermally stable, making them ideal for high-temperature applications in electronic and magnetic devices.

- Customizable Size and Shape: IrMn sputtering targets are available in various sizes and shapes, including discs, plates, and custom geometries, to suit a wide range of deposition systems.

-

- High Transparency and Conductivity: ITO offers a balance of excellent transparency in the visible spectrum and good electrical conductivity, making it a perfect material for applications requiring both.

- Adjustable Stoichiometry: The ratio of In2O3 to SnO2 in ITO can be adjusted to optimize its electrical and optical properties for specific applications.

- Thin-film Uniformity: ITO films are known for their uniform thickness and quality, essential for ensuring consistent performance across large-area coatings like touchscreens and solar panels.

- Durability: ITO films are chemically stable and durable, providing long-term performance in various environmental conditions.

- Custom Purity Levels: ITO sputtering targets are available in a variety of purities (up to 99.999%) to meet the stringent requirements of high-performance electronic and optical devices.

-

- High Optical Transparency: Enables the creation of efficient transparent films.

- Superior Conductivity: Provides excellent electrical performance for electronic applications.

- Thermal and Chemical Stability: Ensures reliability in high-temperature and reactive environments.

- Customizable Material Composition: Optimized for specific TCO requirements.

- Compatibility: Suitable for RF and DC sputtering systems.

-

Lanthanum sputtering targets are crucial for creating thin films with specific electronic, optical, and catalytic properties, making them valuable in advanced technologies such as semiconductors, optics, superconductors, and energy storage systems. Despite its reactivity, lanthanum’s unique characteristics provide significant advantages in various high-tech industrial and scientific applications.

-

- High Dielectric Constant: La₂O₃ exhibits a high dielectric constant, making it an excellent material for advanced electronic components, such as gate dielectrics in MOSFETs.

- High Refractive Index: Its high refractive index makes it ideal for enhancing optical properties in coatings for lenses, filters, and other precision optical devices.

- Thermal and Chemical Stability: La₂O₃ is highly stable under extreme temperatures and chemically resistant, making it suitable for high-performance applications.

- Catalytic Efficiency: Lanthanum oxide’s catalytic properties are leveraged in thin films used for environmental and energy applications.

-

- High Dielectric Constant: LaAlO₃ has a high dielectric constant (k-value), which enhances its performance in capacitors and other high-k dielectric applications.

- Thermal Stability: LaAlO₃ exhibits excellent thermal stability, making it ideal for high-temperature processing and devices that operate in extreme environments.

- Structural Integrity: The perovskite structure of LaAlO₃ contributes to its high mechanical strength and chemical stability, ensuring long-lasting performance in demanding applications.

- Oxide Electronics: LaAlO₃ is widely used in complex oxide electronics due to its ability to form high-quality interfaces with other materials like SrTiO₃ and LaNiO₃.

-

- High Thermal Stability: Performs well in high-temperature environments.

- Superior Electrical Conductivity: Ideal for electronic and thermionic applications.

- Low Work Function: Enables efficient electron emission.

- Oxidation Resistance: Long-lasting performance under challenging conditions.

- Customizable Specifications: Tailored to meet specific application needs.

-

- Exceptional Ionic Conductivity: Enhances energy transfer in battery technologies.

- Stable and Durable: Chemically stable under a wide range of operating conditions.

- High Dielectric Constant: Ideal for electronic and capacitor applications.

- Customizable: Available in multiple sizes, shapes, and purity levels to meet specific application needs.

- Compatible: Works efficiently with various sputtering deposition systems.

-

- High Purity: Guarantees low contamination for critical applications.

- Chemical Stability: Resistant to degradation, ensuring durable coatings.

- Superior Ionic Conductivity: Optimal for battery and energy storage films.

- Consistent Deposition: Ensures uniform and reliable thin-film performance.

- Customizable Dimensions: Adaptable to different sputtering systems and requirements.

-

$1.00 – $424.00

- High Stability: Li₄Ti₅O₁₂ has excellent chemical and structural stability, making it an ideal material for long-lasting energy storage devices.

- Low Volume Expansion: This material shows minimal expansion and contraction during charge/discharge cycles, improving battery longevity.

- Thermal Safety: Li₄Ti₅O₁₂ has a high thermal stability, reducing the risk of overheating in energy storage devices.

- Fast Charging Capability: The material is recognized for its fast charge/discharge properties, making it suitable for high-performance batteries.